You face a critical decision every time you evaluate acetate as your premium eyewear material. You must balance superior aesthetics against manufacturing complexities, sustainability claims against chemical realities, and artisanal quality against scalable production costs. This analysis provides the manufacturing-level insights you need to build both an informed product strategy and a rigorous partner selection framework.

Why Acetate Justifies a Premium Price

Deconstructing Cellulose Acetate: Core Properties

Cellulose acetate’s unique molecular structure fundamentally shapes your product development. This plant-based thermoplastic combines renewable wood pulp with specific plasticizers. This creates a material with distinct advantages over petroleum-based alternatives while introducing manufacturing considerations that directly impact your cost structure and quality standards.

Translating Material Superiority into Premium Features

Acetate’s plant-based origin provides your brand with legitimate sustainability credentials while delivering tangible performance benefits that justify premium pricing. Unlike petroleum-based plastics that rely on fossil fuel extraction, acetate derives from renewable cellulose sources, primarily wood pulp from sustainably managed forests.

The material’s thermoplastic properties enable post-production adjustability, which creates genuine value. When heated to controlled temperatures, acetate becomes moldable, allowing opticians to customize frame fit without compromising structural integrity. This adjustability translates into reduced return rates and enhanced customer satisfaction.

Critical Warning: Quality acetate requires extended curing periods of 12-18 months. Partners who rush this timeline compromise material stability, leading to warping and discoloration that damages your brand reputation and increases warranty claims.

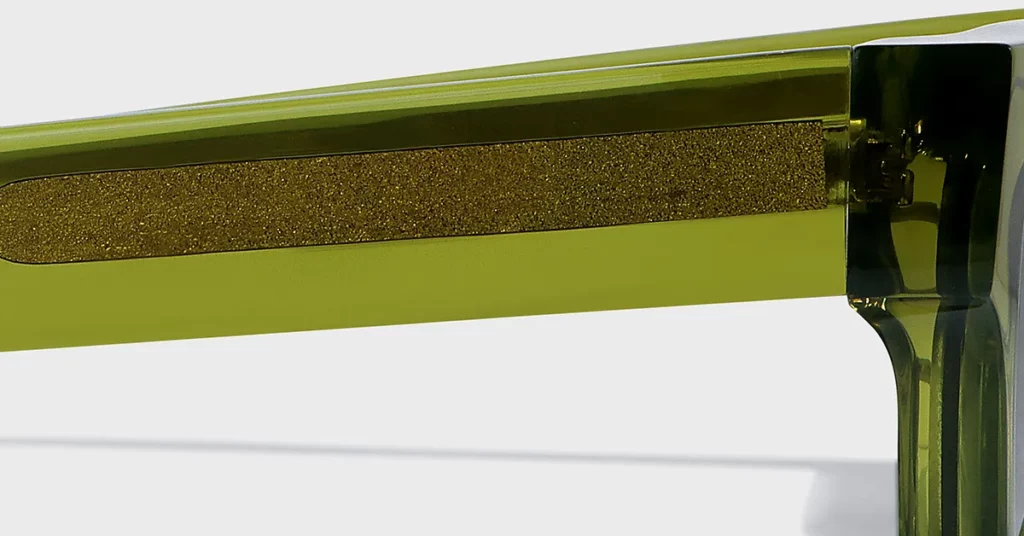

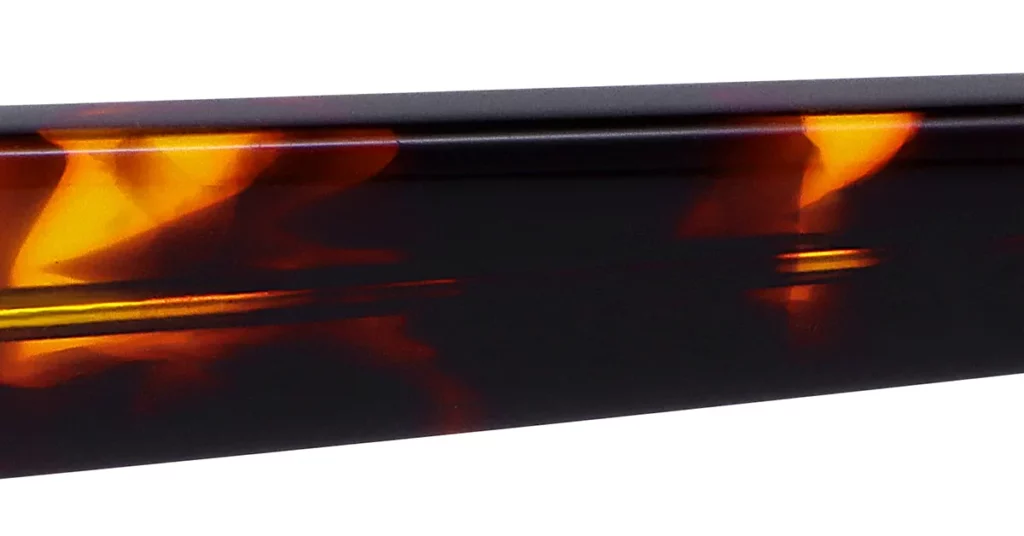

The Science of Color: Leveraging Layered Block Acetate

Block acetate’s layered construction creates color depth impossible to achieve through surface treatments. Multiple acetate sheets are pressed together, creating blocks where patterns and colors extend completely through the material. This manufacturing approach eliminates the color fading and peeling common in painted frames, supporting your brand’s durability claims and reducing warranty costs.

For Example: Mazzucchelli’s tortoiseshell patterns use up to seven different acetate layers to create dimensional depth. This makes premium frames instantly recognizable compared to printed or surface-applied alternatives. Manufacturers can create gradient effects, embedded patterns, and even metallic inclusions, enabling distinctive product differentiation.

Engineering for Comfort and Market Expansion

Acetate’s hypoallergenic properties expand your addressable market to consumers with metal sensitivities. Unlike frames containing nickel, properly processed acetate causes minimal skin reactions. This reduces customer complaints and opens opportunities in sensitive skin market segments.

The material’s weight creates a perception of quality while remaining comfortable for extended wear. Consumer psychology indicates that frames perceived as “too light” are associated with cheap construction, making acetate’s weight profile ideal for premium positioning.

Key Metric: Acetate frames weigh approximately 40% more than TR90 alternatives but 30% less than comparable metal frames. This hits the optimal weight range for premium perception while maintaining day-long comfort.

The Tactile Signature: Driving Perceived Value

Acetate’s natural luster and substantial hand-feel create an immediate quality perception that supports premium pricing. The material’s molecular structure allows for deep polishing that produces mirror-like surfaces impossible to achieve with most injection-molded alternatives. The 48-76 hour barrel tumbling process used in quality acetate finishing creates surfaces that feel substantial and refined.

Best Practice: Specify hand-polishing for visible frame areas and machine polishing for interior surfaces. This approach optimizes both aesthetic impact and cost control while maintaining the premium tactile experience that drives sales at the retail level.

The Perfect Fit as a Feature: Using Thermoplastic Adjustability

Acetate’s thermoplastic nature, combined with an embedded metal core wire in the temples, creates adjustability that becomes a genuine product feature. This capability extends the product lifecycle by maintaining a proper fit as a customer’s needs change over time.

Pro Tip: Partner with manufacturers who provide detailed adjustment protocols to your retail partners. Proper heating to 60-70°C is required; temperatures above this threshold cause the material to degrade, creating brittleness and potential cracking. This ensures consistent procedures that deliver customization benefits.

How to Engineer Around Acetate’s Inherent Risks

Proactively Engineering Around Material Limitations

Every material presents trade-offs. Acetate’s limitations require proactive engineering to prevent customer dissatisfaction and warranty claims. Understanding these constraints enables you to design products that maximize acetate’s advantages while minimizing exposure to its inherent weaknesses.

Mitigating Risk: Designing for Heat Sensitivity

Acetate’s thermoplastic nature creates a vulnerability to heat-related deformation. Frames left in hot cars or exposed to direct sunlight risk warping that cannot be corrected. Design solutions include frame geometry that distributes stress evenly and thicker sections in critical areas to provide greater thermal mass.

Critical Warning: Avoid acetate for products targeting extreme climate markets or outdoor sports. The material’s 60°C sensitivity threshold makes it unsuitable for these demanding environments. Customer packaging must include clear care instructions to set appropriate expectations.

Managing the Product Lifecycle: Setting Warranty Policies

Acetate’s relatively soft surface accepts scratches more readily than harder alternatives. However, it also enables repair and refinishing that extends the product lifecycle. Your warranty policies must acknowledge these material characteristics while maintaining customer confidence.

- Chemical Sensitivity: Premium grades using non-phthalate plasticizers show superior resistance to cosmetics and cleaning products compared to economy alternatives.

- Age-Related Brittleness: This emerges as plasticizers migrate from the material. Quality acetate maintains flexibility for 5-7 years, while inferior grades may become brittle within 2-3 years.

- Repair Services: Establish relationships with specialists who can refinish scratched acetate. This offers customers a restoration service that extends product life and reinforces your commitment to longevity.

Strategic Trade-Offs: Positioning Acetate’s Weight

Acetate’s 22-25 gram average weight positions it between ultralight TR90 (8-10 grams) and premium titanium (9-12 grams). Your market positioning must acknowledge this weight trade-off while emphasizing the benefits that justify the additional mass, such as adjustability and color depth.

The Bottom Line: Position acetate’s weight as a “substantial feel” rather than “heavy.” Emphasize the quality perception benefits while targeting customers who prioritize aesthetics and a custom fit over minimal weight.

How to Build a Defensible Sustainability Narrative

Building an Authentic Sustainability Narrative

Sustainability claims require substantiation with verifiable data and transparent supply chain documentation. Acetate’s plant-based origin provides legitimate environmental advantages, but these benefits depend entirely on sourcing practices, processing methods, and end-of-life considerations.

Deconstructing “Bio-Acetate”: Separating Fact from Marketing

Bio-acetate is a significant advancement, but marketing claims often exceed actual environmental benefits. Legitimate bio-acetate must contain a minimum of 62% plant-based content per ISO 14855 standards. Many products marketed as “bio-acetate” contain far lower percentages.

Definition: True bio-acetate must meet specific criteria to qualify for legitimate environmental claims. This includes a minimum 62% plant-based content, ISCC Sustainability Carbon Certification, ISO 14855 biodegradability compliance, and freedom from toxic plasticizers. You must demand detailed composition documentation from suppliers.

Sourcing for Trust: Certifications & Plasticizers

Wood pulp sourcing directly impacts your environmental credibility. FSC (Forest Stewardship Council) and PEFC certifications provide third-party verification of sustainable forestry practices that support authentic environmental positioning.

The use of non-phthalate plasticizers is a technical rule that eliminates health concerns and improves biodegradability. This operational choice mitigates future regulatory risk and aligns your product with modern consumer safety expectations.

Critical Warning: Avoid suppliers who cannot provide complete supply chain documentation. Undocumented sourcing creates liability for false environmental claims and regulatory compliance issues that can result in significant financial and reputational damage.

Addressing the Full Environmental Impact

Biodegradability claims require careful qualification. While acetate can biodegrade under specific industrial composting conditions, standard landfill environments lack the necessary oxygen and microbial activity for decomposition. This makes its end-of-life impact more complex than marketing suggests.

For Example: M49 bio-acetate formulations achieve complete biodegradation within 120 days under composting conditions. This demonstrates a viable pathway for genuine environmental improvement, but you must be transparent with customers about the required disposal conditions.

Why Your Manufacturing Method Defines Your Brand

The Manufacturing Crossroads: Aligning Method with Strategy

Your choice between block acetate craftsmanship and injection molding efficiency fundamentally shapes your product strategy. This decision impacts everything from price points and design possibilities to your target market. Understanding the technical and economic implications enables strategic alignment between manufacturing capabilities and brand objectives.

| Manufacturing Attribute | Block Acetate (Artisanal) | Injection Molding (Scalable) |

| Core Method | Frames are CNC-milled from solid, cured blocks of layered acetate. | Thermoplastic pellets (e.g., TR90) are melted and injected into a steel mold. |

| Material Waste | High (40-60%), as shapes are cut from rectangular blocks. | Minimal (<5%), with runners often being recycled into the process. |

| Cost Structure | Low tooling cost, high per-unit labor and material cost. | High initial mold investment ($15k-$50k), very low per-unit cost at volume. |

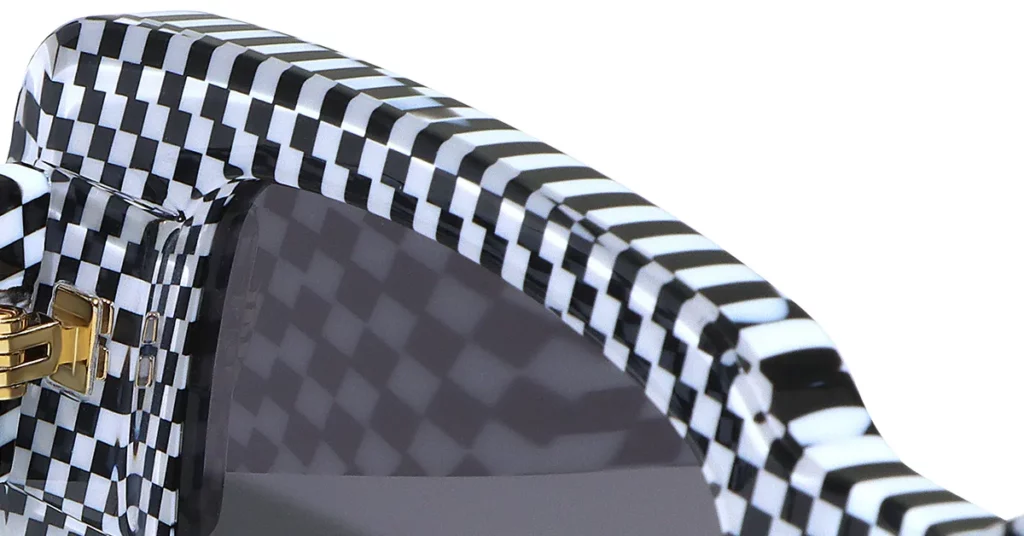

| Design Capability | Unlimited. Allows for intricate, embedded, multi-tonal patterns. | Limited to solid colors or simple multi-shot effects. No embedded patterns. |

| Adjustability | Fully adjustable via an embedded metal core wire in the temples. | Typically no metal core, making the frame non-adjustable for a custom fit. |

| Ideal Use Case | Premium fashion and luxury lines where aesthetics and feel are paramount. | Performance, sports, or price-sensitive lines where scalability is key. |

The Block Acetate Method: The Foundation of Quality

Block acetate manufacturing represents the pinnacle of eyewear craftsmanship. This approach requires significant investment in skilled labor and extended production timelines but enables design possibilities and quality levels unachievable through other methods.

The Process Deconstructed

- Curing: Production begins with a 12-18 month curing process for premium blocks, creating stable material that resists warping.

- CNC Milling: Raw blocks are milled into precise components with tolerances within ±0.1mm, ensuring consistent fit.

- Tumbling: A 48-76 hour barrel tumbling process with beech and birch wood chips achieves the mirror-like surface finish.

- Polishing: Multiple hand-polishing stages create the depth and clarity customers associate with luxury products.

The ROI of Craftsmanship: Analyzing Costs vs. Brand Equity

Block acetate manufacturing generates 40-60% material waste and requires significantly more skilled labor. However, this investment enables product differentiation and premium pricing that can generate 200-300% margin improvements over mass-market alternatives.

Best Practice: Calculate total value creation rather than focusing only on manufacturing costs. The premium positioning enabled by block acetate craftsmanship often generates profit margins that dwarf the additional production expenses while building long-term brand equity.

Unlocking Design Freedom: The Choice for Intricate Patterns

Complex pattern creation requires the layered construction only possible with block acetate. Multiple colored sheets pressed together create patterns that extend through the material, ensuring they never fade or peel. This allows for gradients and color flows that make each frame a unique artistic statement.

For Example: Mazzucchelli’s advanced block construction enables embedded wood grain patterns with over 20 distinct color variations. This creates remarkable realism while providing the durability and adjustability impossible with actual wood materials.

Finishing as a Key Differentiator

You must choose between hand-polishing and lacquering. Hand-polishing creates superior surface depth and clarity. Lacquering is faster but can chip or peel over time and prevents effective repairs, creating warranty issues.

The Bottom Line: Hand-polishing requires 3-4 times longer but creates visual and tactile characteristics that justify premium pricing. It also enables repair services that enhance customer satisfaction and create additional revenue opportunities.

The Injection Molding Method: The Path to Scalability

Injection molding offers compelling advantages for brands prioritizing scalability, cost control, and speed to market. This approach enables high-volume production with minimal labor, providing design flexibility sufficient for many market applications.

The Process Deconstructed

Injection molding transforms thermoplastic pellets (like Nylon or TR-90) into finished frames via high-pressure injection into a precision steel mold. The process typically requires only 30-60 seconds per frame, enabling immense production volumes. Automated finishing processes then remove molding flash and apply surface treatments with minimal labor.

Key Metric: Initial mold investment for injection molding ranges from $15,000-$50,000 per design. However, this enables per-unit costs that are 60-80% lower than block acetate alternatives once a volume threshold of 5,000-10,000 units is met.

The Financial Model

The economics of injection molding favor high-volume production where the initial mold cost can be amortized across thousands of units. Material efficiency is extremely high, approaching 95-98%, which significantly impacts margins on large production runs. This method provides the scalability needed to meet seasonal demand surges without proportional increases in labor costs.

The Inevitable Compromise

Injection molding creates uniform material, which eliminates the possibility of layered, embedded patterns. This limits you to surface-level colors, which can lack depth and are prone to wear.

Critical Warning: Injection-molded frames typically lack the metal core wire systems essential for professional adjustment. This limitation prevents fit customization, which can lead to lower customer satisfaction and higher return rates compared to adjustable acetate frames.

A Use-Case Analysis

Injection-molded frames excel in applications requiring extreme flexibility and impact resistance, where acetate’s rigidity is a liability. Materials like TR90 provide exceptional recovery from deformation, making them ideal for performance and sports-focused lines.

Best Practice: Deploy injection molding for performance-focused product lines where function outweighs aesthetic considerations. Reserve block acetate for fashion-focused applications where visual impact, tactile feel, and adjustability create the primary value.

How Acetate Wins in a Competitive Landscape

The Competitive Landscape: A Comparative Analysis

Effective positioning requires identifying your target customer’s priorities and showing how your chosen material delivers superior value for those specific needs. This approach enables premium pricing and builds sustainable competitive advantages.

Acetate vs. Standard Petroleum-Based Plastics

| Attribute | Cellulose Acetate | Petroleum-Based Plastics |

| Material Source | Plant-based (renewable wood pulp and cotton fibers). | Fossil-fuel-based (non-renewable petroleum). |

| Color Quality | Color is embedded through the entire material; will not chip or fade. | Color is a surface coating or paint; prone to chipping and peeling. |

| Adjustability | Fully adjustable for a custom fit via an integrated metal core wire. | Not adjustable; fit is fixed, limiting comfort and customization. |

| Quality Perception | Substantial hand-feel and high-gloss luster are perceived as premium. | Often feels lightweight and less substantial, perceived as lower quality. |

Acetate vs. Metal Frames (Titanium, Stainless Steel)

| Attribute | Cellulose Acetate | Metal Frames |

| Hypoallergenic | Naturally hypoallergenic, preventing skin irritation for all wearers. | Can contain nickel, causing skin irritation for 10-15% of the population. |

| Weight & Profile | Heavier, “substantial” feel (22-25g) that allows for bold shapes. | Lighter, minimalist profile (9-18g) for a less visible look. |

| Color & Finish | Inherent color runs through the material and can be re-polished. | Relies on coatings (plating, paint) that can chip, scratch, or wear off. |

| Adjustability | Temples and frame front are highly adjustable for a perfect fit. | Limited adjustability, primarily at the nose pads and temple tips. |

Acetate vs. High-Performance Polymers (TR90)

| Attribute | Cellulose Acetate | High-Performance Polymers (TR90) |

| Target Market | Premium fashion and lifestyle, where aesthetics are the priority. | Athletic and children’s eyewear, where flexibility is the priority. |

| Aesthetic | Rich, deep colors and a high-luster polish are achievable. | A matte, utilitarian finish with limited color and pattern options. |

| Adjustability | Fully adjustable via a metal core for a customized, secure fit. | Not adjustable; relies on material flexibility to grip the head. |

| Impact Resistance | Good durability and flexibility, but can break under high impact. | Extremely flexible and virtually unbreakable; ideal for sports. |

The Blueprint for Vetting a Manufacturing Partner

The Partner Vetting Blueprint

Choosing the right manufacturer determines whether your acetate sunglasses deliver on their quality promise or become a warranty nightmare. This framework enables a systematic evaluation of critical capabilities.

Auditing Material Sourcing and Handling

Material quality forms the foundation of your product. Partners who understand acetate’s unique requirements and maintain proper sourcing relationships demonstrate the competency essential for consistent quality.

- Verify Provenance: Demand specification sheets for materials, especially from premier suppliers like Italy’s Mazzucchelli or top Japanese producers.

- Assess Curing: A partner’s protocol for curing blocks reveals their commitment to quality. Demand documentation proving a 12-18 month curing period.

- Ensure Integrity: Require Material Safety Data Sheets (MSDS) for all inputs to verify the use of non-phthalate plasticizers and confirm cellulose purity.

Evaluating Core Manufacturing Craftsmanship

Manufacturing capability assessment requires a systematic evaluation of equipment, processes, and quality systems. This determines the final product quality and consistency.

- Distinguish Crafting from Molding: You must verify the presence of CNC milling machines and barrel tumbling systems. A facility that relies only on high-pressure molding equipment cannot produce true block acetate frames.

- Evaluate Hinge Integration: Prioritize partners who use heat-inserted hinges. This technique creates a molecular bond with the acetate, distributing stress and preventing failures common with cheaper riveted hinges.

- Conduct the Hand-Polish Test: A flawless, mirror-like finish is a key indicator of a partner’s commitment to premium finishing. Request samples to visually confirm their hand-polishing capabilities.

Mitigating Risk: Reviewing QC Protocols

A partner’s Quality Control (QC) system is your primary defense against defects and inconsistency. A mature QC protocol is a non-negotiable requirement for any premium product line.

Key Metric: Quality partners maintain color variation tolerances within ΔE<2.0 across production batches. Demand to see their color-matching procedures and equipment. Review their defect tracking systems to understand their historical performance and commitment to process improvement.

Conclusion

Understanding acetate’s manufacturing complexities—from the distinction between 18-month cured blocks versus rushed alternatives to the precision of hand-polishing—empowers you to develop superior products. Your success depends on matching material properties to your target market while selecting partners who can execute on your brand’s quality promise. Kssmi’s two decades of acetate expertise provides the manufacturing partnership essential for translating your vision into market-leading products that build lasting brand equity.

Frequently Asked Questions

1. How does acetate curing time impact frame durability?

Answer: A proper 12-18 month curing period allows solvents to evaporate and internal stresses to relax. This creates a stable material that resists warping and cracking for 5-7 years. Rushed curing leads to premature failure and adjustment issues.

2. What is the cost difference between block vs. painted acetate?

Answer: Block acetate’s embedded color requires a longer, more wasteful process but will never peel or fade. Creating a similar look via injection molding and surface painting can cut unit costs by 60-70% but introduces high warranty risk from coating failure.

3. How do I verify a supplier uses bio-based plasticizers?

Answer: Demand a full Material Safety Data Sheet (MSDS) identifying all chemical components. Require third-party lab analysis confirming the absence of phthalates and verify bio-based content percentages with ISCC, FSC, or PEFC certifications.

4. How do heat-inserted vs. riveted hinges affect frame life?

Answer: Heat-inserted hinges create a strong molecular bond with the acetate, distributing stress evenly. Riveted hinges concentrate stress at the insertion point, making them a common failure point that can lead to cracking and loosening.

5. How do I calculate material waste for acetate vs. injection molding?

Answer: Cutting frames from block acetate generates 40-60% material waste. Injection molding waste is typically under 3% due to runner recycling. However, a true sustainability analysis must also account for energy use, chemical processing, and biodegradability.