Your eyewear supply chain has four main levels, or tiers, that take a product from raw material to retail. Tier 3 provides basic materials like acetate resin. Tier 2 turns those into components like hinges. Tier 1 is your factory, assembling the final frames. Tier 0 is your brand, managing the final sale and delivery to your customers.

First, A Map of the Journey: Understanding Supply Tiers

You need to understand that these tiers matter because they give you a map of your entire production landscape. This means you can pinpoint exactly where your product is at any given time and who is responsible for it. Think of it like building a house: you have a supplier for raw lumber (Tier 3), a craftsman who builds the wall frames (Tier 2), and a general contractor who assembles the house (Tier 1). Knowing who does what is the first step to managing the project successfully.

Most Importantly: A problem with your raw material supplier (Tier 3) will bring your final assembly factory (Tier 1) to a complete halt. A smart brand manager understands how all of these tiers are connected.

Tier 3 (The Origin): Raw Material Suppliers

This tier is the absolute foundation of your product, representing the source of its most basic ingredients. These suppliers are responsible for extracting and refining the fundamental substances, like acetate resin or titanium ore, that will eventually become your frames. They are the miners and chemical plants at the very beginning of the chain.

Tier 2 (The Parts): Component & Material Processors

Tier 2 is where raw materials become usable parts. These specialized factories take the basic substances from Tier 3 and transform them into the finished components your assembly partner will use. Their work requires unique equipment and deep expertise in one specific area.

For Example: This is where a company like Mazzucchelli turns acetate resin into beautifully patterned sheets, or a specialist factory produces high-quality hinges and nothing else.

Tier 1 (The Product): The Finished Goods Factory

This is your primary partner—the factory that assembles all the individual components into the complete, finished eyeglasses. Your Tier 1 partner manages the final, critical manufacturing processes that determine the quality, fit, and durability of the product your customer will hold. This is your master chef, combining all the ingredients.

Tier 0 (Your Business): Brand Headquarters & Operations

This final tier is you. It is your office, your warehouse, and your website—the part of the supply chain where you have direct control over the customer experience. Everything from managing your inventory to handling customer service and marketing happens right here at Tier 0.

Stage 1: From Dream to Design – The Eyewear Concept

The Spark: Defining Your Brand and Customer

Every great eyewear brand begins with a clear answer to a simple question: who are you designing for? The answer to this question—your target audience—drives every single decision that follows, from the materials you choose to the price you set. A luxury brand and a sports brand require entirely different partners and processes.

Best Practice: Create a detailed mood board to translate your brand idea into a concrete visual language. This becomes a powerful communication tool that closes the gap between your creative vision and your partner’s technical execution.

The Blueprint: Creating Your Tech Pack

The tech pack is the single most critical document in your entire supply chain. This is your master blueprint, containing every technical specification—from precise dimensions and material codes to logo placement. Its purpose is to eliminate any chance of misunderstanding between your design vision and the factory’s execution, acting as the ultimate source of truth for your product.

Remember This: Every detail in your tech pack, like CAD files and Pantone color codes, has a direct impact on your supply chain. An incomplete or inaccurate tech pack is the primary cause of costly production errors.

The Test: Prototyping Your Idea

A prototype is your first chance to see if your design works in the real world before you commit to producing thousands of them. The purpose is to test the fit, function, and feel of the frames, allowing you to catch problems when they are cheap to fix.

Common Mistake: Skipping the prototype stage to save time or money. This is the most expensive mistake you can make, as a flaw discovered during mass production can jeopardize your entire investment.

Stage 2: Sourcing the Soul – Materials & Components

The Foundational Decision: Choosing Your Frame Material

Your choice of frame material is the most important decision you will make in the sourcing stage. This single choice affects your manufacturing process, your brand’s story, and your final price point. Each material requires completely different Tier 2 and Tier 3 partners.

Option 1: Cellulose Acetate (The Artisan’s Choice)

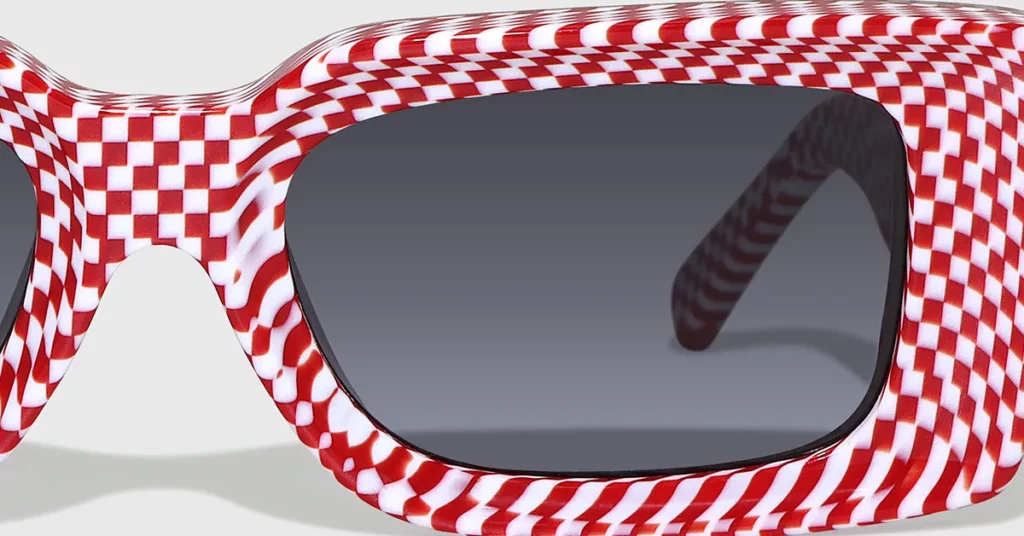

Cellulose acetate is a bio-based plastic that signals craftsmanship and luxury. Its main advantage is its unmatched potential for rich color and pattern depth, giving each frame a unique, premium appearance. The layers of color create a visual effect that is impossible to achieve with other materials.

| Feature | Italian Acetate | Japanese Acetate |

| Color Vibrancy | Exceptional depth and richness | Good color clarity |

| Durability | Moderate hardness | Superior hardness & density |

| Pattern Options | Nearly unlimited custom patterns | More limited standard patterns |

| Cost Impact | Higher material costs | Moderate material costs |

The Bottom Line: Acetate carries a higher material cost but allows you to build a brand around a story of artisan quality and handmade appeal. It’s the go-to choice for premium, independent eyewear brands.

Option 2: Metal (The Engineer’s Choice)

Metal frames are for customers who value durability, precision, and a clean aesthetic. Metal allows for much thinner and more refined designs while maintaining excellent strength. Titanium, in particular, offers the highest strength-to-weight ratio of any eyewear material.

| Feature | Stainless Steel | Titanium |

| Weight | Moderate and sturdy | Ultra-lightweight |

| Corrosion Resistance | Good | Excellent, resists sweat & salt |

| Hypoallergenic | Generally good | 100% hypoallergenic |

| Cost Structure | Lower material costs | Premium material costs |

The Bottom Line: Metal is perfect for creating a minimalist, modern, or industrial aesthetic. Stainless steel offers a great balance of cost and performance, while titanium is the clear choice for the high-end, performance-focused market.

Option 3: Injection Plastic (The Scalable Choice)

Injection molding is built for high-volume, high-consistency production. This process is the key to achieving a lower per-unit cost, making it the ideal choice for sports eyewear, children’s lines, or any brand planning for significant scale.

Critical Warning: While the per-unit cost is low, injection molding requires a massive upfront investment. The steel molds are extremely expensive to create, often costing tens of thousands of dollars for a single design. This path is best for brands with large, confirmed orders.

Sourcing Functional Parts: The Tier 2 Ecosystem

Beyond the frame itself, small functional components have a huge impact on the final product’s quality. Sourcing these parts involves building relationships with a network of specialized Tier 2 suppliers.

Component Focus: The Hinge

The hinge is the hardest-working part of any pair of glasses and a key indicator of its long-term durability. A better hinge leads to higher customer satisfaction and a stronger brand reputation.

Key Metric: Focus on the barrel count (3, 5, or 7). A higher count, like a 5-barrel hinge, distributes stress across more points. This makes the frame feel more solid and prevents the hinge from becoming loose over time.

Component Focus: The Lens

The lens is how your customer experiences the world, and its quality is a major factor in their perception of value. Different lens properties require different suppliers and add specific costs and manufacturing steps to your production plan.

Pro Tip: Decide early what functional properties your lenses need, such as UV protection, polarization, or blue light filtering. Each feature adds a layer of complexity and cost that you must account for in your planning.

Stage 3: The Art of Assembly – The Tier 1 Factory

Path A: Crafting an Acetate Frame

Acetate manufacturing is a process of subtraction and refinement. It begins with a solid block or sheet of material and uses skill and precision to carve it into a polished, finished frame.

- Step 1: CNC Machining: A computer-controlled machine precisely cuts the frame front and temples from the patterned acetate sheets. This ensures every piece is dimensionally perfect.

- Step 2: Core Wire Insertion: A metal wire is heated and skillfully inserted into the acetate temples. This provides the strength and adjustability needed for a perfect fit.

- Step 3: Tumbling: The cut parts are tumbled for over 72 hours in barrels filled with small wood chips. This slow, gentle process is what smooths all the rough edges without damaging the material.

- Step 4: Hand-Polishing: An artisan uses a series of buffing wheels to polish the frame. This final, manual step is what creates the deep, high-gloss luster that defines premium acetate.

Path B: Creating an Injection-Molded Frame

Injection molding is a story of heat and pressure. This manufacturing path is designed for speed, efficiency, and consistency across thousands of identical units.

The Bottom Line: The most important step is the creation of the expensive steel molds. The quality of this initial tool determines the precision of every frame you produce. The high upfront cost is traded for a much lower per-unit cost during mass production.

Final Touches: Where the Brand Comes to Life

These finishing steps transform a well-made product into a piece of your brand.

- Logo Application: Your logo can be applied via laser engraving, printing, or a metal inlay. The method you choose should reflect your brand’s aesthetic and commitment to durability.

- Glazing: This is the craft of cutting the lenses to the perfect shape and fitting them securely into the frame. Precise glazing is critical for both optical performance and safety.

- Bench Alignment: Before shipping, every single frame gets a final four-point alignment on a technician’s bench. This ensures the frame is perfectly balanced and sits straight, a critical final touch for professional-grade eyewear.

Stage 4: The Global Journey – Logistics & Quality

Quality Assurance: Your Eyes on the Factory Floor

Quality control is your system for ensuring the products you paid for meet the standards you promised your customers. An effective QA plan protects your financial investment and your brand’s reputation.

Definition: You will use the AQL (Acceptable Quality Level) standard. This is a statistical system that defines how many minor or major defects are acceptable in a batch before you reject it. It balances the need for quality with commercial reality.

Best Practice: Always perform a pre-shipment inspection. This is your last and best chance to find and fix errors before you send the final payment and the goods leave the factory. You can use the factory’s report or hire an independent third-party inspector for unbiased results.

International Shipping: Factory to Warehouse

Global logistics is the process of moving your finished goods from the factory to your warehouse. Your choice here is a direct trade-off between cost and speed.

| Method | Transit Time | Cost Impact | Reliability | Best For |

| Air Freight | 3-7 days | Very High | Very Reliable | Urgent orders, small batches |

| Sea Freight | 15-45 days | Low | Less Reliable | Large orders, planned inventory |

The Bottom Line: Your choice here is a direct trade-off between speed and cost. Air freight gets your product to market faster, ideal for urgent needs, while sea freight maximizes your profit margin on large, planned inventory shipments.

Remember This: You must work with a freight forwarder. They are the experts who will handle the complex process of customs clearance and ensure all import duties and tariffs are paid correctly.

Packaging: Protection and Experience

Packaging has two equally important jobs. The first is to protect your product and ensure it arrives safely after its long journey. The second is to create the “unboxing experience” that communicates the premium value of your brand.

Stage 5: The Last Mile – Warehouse to Customer

Warehousing and Inventory Management

This is the process of storing your bulk inventory and managing it so you can fulfill individual customer orders. Your choice is between storing it yourself or partnering with a 3PL (Third-Party Logistics) company.

Pro Tip: For most new brands, using a 3PL is the smartest choice. They are experts in the complex work of storing, picking, packing, and shipping. Outsourcing this frees you up to focus on what you do best: building your brand.

Fulfillment & Reverse Logistics

Fulfillment is the physical act of picking a product from a shelf, packing it in a box, and shipping it to a customer. Speed and accuracy here are critical for customer happiness. Reverse logistics is the process for handling customer returns, which is an inevitable part of selling eyewear.

Remember This: Your returns process is a crucial part of your brand experience. A simple, fair, and easy returns policy is one of the most powerful tools you have for building customer trust and encouraging repeat business.

Conclusion

The eyewear supply chain is not just a factory; it is a long, interconnected journey that relies on a chain of skilled partners. Each tier, from the raw material supplier to your final assembly factory, adds critical value. Understanding this entire path from start to finish empowers you to make smarter decisions, anticipate challenges, control costs, and build a resilient, high-quality brand that customers will love and trust for years to come.

Frequently Asked Questions

1. How long does the entire eyewear supply chain process take?

A typical timeline is 4-6 months for a new product. This includes about 4-8 weeks for design and prototyping, 2-4 weeks for sourcing, 6-8 weeks for manufacturing, and another 2-4 weeks for shipping and logistics.

2. What is the biggest supply chain mistake new eyewear brands make?

The most common mistake is skipping the prototype phase or choosing a factory based only on the lowest price. This almost always leads to serious quality issues, delays, and unexpected costs that can ruin a brand launch.

3. What is a realistic MOQ for a first production run?

For acetate frames, expect a Minimum Order Quantity (MOQ) of 300-500 units per style. For metal, it’s often 100-300 units. For injection-molded frames, MOQs are much higher, usually starting at 1,000-3,000 units per style.

4. How much should I budget for shipping and import duties?

A safe estimate is to budget 15-25% of your product’s manufacturing cost to cover shipping, duties, and logistics. Air freight can be higher, while sea freight is typically in the 10-20% range.

5. Why can’t I just use a factory from a B2B marketplace?

Building quality eyewear requires verifying a partner’s specialized skills, equipment, and quality systems. Rushing this critical vetting process often leads to communication problems, poor quality, and delays that cost much more in the long run.