Thick acetate frames (4mm-10mm) offer bold aesthetics and maximum strength, making them ideal for high prescriptions but adding significant weight. Thin acetate frames (1.5mm-3mm) provide exceptional comfort and a minimalist look, but they demand high-density materials to avoid feeling flimsy. Your choice is a strategic balance between visual impact and wearer ergonomics.

The Core Trade-Offs for Designers

Understanding acetate thickness isn’t just about looks—it’s about preventing the real-world problems your customers complain about. The thickness you select creates a cascade of effects, from the cost of raw materials to the way a frame feels on someone’s face after eight hours of wear. Making an uninformed choice can lead to costly returns and a damaged brand reputation.

At a Glance: Thick vs. Thin Acetate

To make a smart decision, you need to see the key differences side-by-side. This table breaks down the five most critical factors that will influence your design, your budget, and ultimately, your customer’s happiness. Focus on how each choice serves a different strategic purpose.

| Design Consideration | Thick Acetate (4mm-10mm) | Thin Acetate (1.5mm-3mm) |

| Weight & Comfort | Heavier feel (25-35g); stable if well-designed | Ultra-lightweight (15-25g); ideal for all-day wear |

| Durability | Maximum impact resistance and structural integrity | Durable only with high-density acetate (HDCA) |

| Lens Compatibility | Excellent for hiding thick, high-prescription lenses | Best for low-to-moderate prescriptions (under ±4.00) |

| Aesthetic Impact | Bold, statement-making, communicates heritage | Clean, minimalist, communicates modern engineering |

| Manufacturing Cost | Higher material usage (+30-40%) | Requires precision tooling and HDCA (+15-35%) |

The Bottom Line: There is no single “best” choice. A thick frame excels at creating a powerful brand statement and solving the technical challenge of high-prescription lenses. A thin frame, when engineered correctly with high-density material, delivers a level of all-day comfort that thicker frames simply cannot match.

Common Problems & Engineering Solutions

In my two decades of helping brands, I’ve seen the same issues appear again and again. They almost always trace back to a mismatch between the frame’s design and the user’s needs. Let’s look at the most common complaints and how to engineer your way around them.

Problem 1: Frames Are Heavy & Slide Down

This is the number one customer complaint in the eyewear world, and it’s a direct result of poor weight management.

- The Symptom: Your customer complains about red marks on their nose. This means the frame’s weight is too concentrated. It typically happens when a frame exceeds 32 grams, creating pressure points that become painful over time.

- The Symptom: The glasses constantly slip. This occurs when the center of gravity is too far forward, often because of heavy lenses, causing the entire fitting to fail. This forces your customer to constantly push their glasses back up—a major annoyance.

- The Symptom: The user reports headaches or temple pressure. This is a classic sign of a frame that is too heavy for its design. The weight creates leverage, transferring excessive pressure to the sides of the head and behind the ears.

The Engineering Solution: High-Density Thin Acetate

You can solve the weight problem by using High-Density Cellulose Acetate (HDCA). This material gives you the strength of a much thicker frame but at a significantly lower weight.

Pro Tip: An HDCA frame can be engineered as thin as 1.5mm while supporting the same prescriptions as 4mm standard acetate. This means you can deliver a durable, stylish frame that your customers will barely feel, eliminating the most common source of returns.

Problem 2: Frames Feel Flimsy or Break

A premium brand cannot afford for its products to feel cheap or fragile. Perceived flimsiness destroys customer confidence and leads to warranty claims that hurt your bottom line.

- The Symptom: Frames break at the hinge points during normal use. This is a classic failure point. As frame thickness drops below 3mm in standard acetate, the stress becomes too concentrated for the material to handle, causing a catastrophic failure.

- The Symptom: Thin temple arms snap under pressure. This often happens where the temple begins to curve. Remember This: The metal wire core, which allows an optician to adjust the frame, can create weak points if not perfectly integrated during manufacturing.

- The Symptom: Customers are concerned about fragility, especially for kids or active users. This is a perception issue that directly impacts sales. People instinctively associate thinness with weakness, so your design must prove that assumption wrong.

The Engineering Solution: Thick Acetate for Integrity

When maximum durability is your primary goal, a thicker frame is the clear winner. Thick acetate (5mm+) provides the raw structural integrity to withstand daily abuse.

Key Metric: The extra material in a thick frame allows you to use robust 5-barrel or 7-barrel hinges. These are significantly stronger and distribute stress more effectively, virtually eliminating the most common point of breakage and ensuring a product that feels substantial and reliable.

Problem 3: High-Prescription Lenses Look Bulky

The dreaded “coke bottle effect” is a major concern for users with strong prescriptions. It’s a technical challenge where your frame design is the only solution.

- The Symptom: The thick edges of the lenses are visible from the side. This happens when a prescription is over ±6.00 diopters, as the lens becomes thicker than the frame itself. This is often a source of self-consciousness for the wearer.

- The Symptom: The eyewear feels heavy and unbalanced. High-prescription lenses can add 8-15 grams of weight, shifting the center of gravity forward and causing the frame to constantly slide down the user’s nose.

The Engineering Solution: Thick Acetate for Concealment

A thick acetate frame (6mm+) is the best tool for this job. It provides the necessary depth to completely hide the edge of a thick lens, creating a clean and aesthetically pleasing profile.

Best Practice: For any prescription above ±5.00, your frame’s thickness should match or exceed the lens’s expected edge thickness. This strategic choice turns a technical problem into a seamless part of the design, giving your customer a product they can wear with confidence.

From Style to Strategy: Business Implications

Your decision on acetate thickness is a business decision. It affects your brand’s message, your manufacturing costs, and your customer’s long-term satisfaction.

Aligning Thickness with Your Brand Archetype

The physical presence of your frame sends a powerful message. Make sure it aligns with the story you want to tell.

- Luxury Heritage: Thick acetate (7mm+) feels substantial and valuable in a customer’s hands. It communicates traditional craftsmanship and justifies a premium price. Think of it like a luxury watch—the weight is part of the appeal.

- Modern Minimalist: Thin acetate (1.5-3mm) signals engineering and innovation. It tells a story of advanced material science, appealing to customers who value precision, technology, and understated sophistication.

- Bold Fashion: Exaggerated thickness (8-12mm) is a deliberate statement. It’s for brands that are built on creative confidence and want to offer a unique product that stands out and starts conversations.

Impact on Durability and Returns

Your thickness choice directly impacts your operational costs. Avoid the common mistake of ignoring how a material choice can affect your return rates.

Critical Warning: Thin frames made from standard, low-density acetate have a much higher failure rate. This leads to warranty replacements and negative reviews that damage your brand’s reputation. Investing in HDCA for thin designs is not a cost—it’s insurance against returns.

The Science Behind the Style

To make truly expert decisions, you need to understand the materials you’re working with. The differences between standard acetate and its high-density counterpart are fundamental.

Standard vs. High-Density Acetate (HDCA)

Not all acetate is created equal. The manufacturing process dramatically changes how the material performs.

- [Core Fact]: Standard acetate has a relatively loose molecular structure.

- [This means…]: There are tiny gaps and inconsistencies within the material itself. While this makes it easy to work with, it limits its strength, especially in thin profiles, and can make it prone to warping over time.

- [Think of it like…]: A loosely packed snowball. It holds its shape, but it can’t withstand much pressure before it starts to fall apart. This is why thin standard acetate frames can feel flimsy.

- [Core Fact]: High-Density Cellulose Acetate (HDCA) is created under extreme pressure.

- [This means…]: The molecules are forced into a tightly compressed, uniform structure with almost no internal gaps. This process dramatically increases its strength, stability, and resistance to aging.

- [Think of it like…]: Compressing that snowball into a hard, dense ball of ice. You’re using the same core material, but the compressed structure makes it vastly stronger and more durable.

Most Importantly: HDCA is the technology that makes strong, ultra-thin frames possible. It solves the classic trade-off between strength and weight, opening up new possibilities for your designs.

How Thickness Impacts Manufacturing

Every millimeter of thickness you add or subtract sends ripples through the entire production process, affecting time, labor, and cost.

The Art of Polishing

The quality of the polish is what separates a good frame from a great one. It’s a highly manual process where thickness plays a huge role.

Definition: A premium polish is a deep, uniform, liquid-like luster across every surface of the frame. It should reflect light without any distortion, which requires multiple stages of tumbling in wood chips followed by skilled hand-buffing.

The complex curves and larger surface area of a thick frame require significantly more hand-polishing time to achieve this finish. A skilled artisan might polish 240 simple, thin frames in a day but only 150 complex, thick ones. This difference in labor is a direct and often underestimated cost.

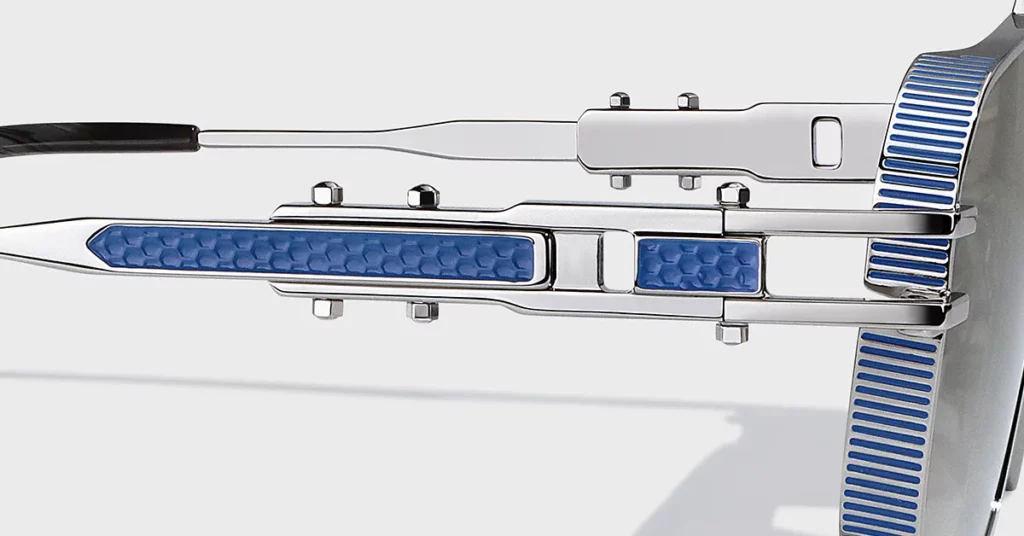

Hardware Integration

Your choice of hinges and wire cores depends entirely on the thickness of the acetate.

For Example: A thick frame (5mm+) can easily accommodate a premium 5- or 7-barrel hinge, which provides superior strength and a smoother feel. A thin frame simply doesn’t have enough material to support this type of robust hardware, limiting your options.

Common Mistake: A poorly inserted wire core in a thin temple is a common failure point. If you can see the wire through the acetate, it signals a low-quality manufacturing process and a high likelihood of future breakage.

Conclusion

Your choice of acetate thickness is a strategic decision that defines your product’s performance, your brand’s message, and your customer’s experience. Move beyond thinking about it as a simple style choice. Instead, see it as an opportunity to build a better, more successful product. By carefully balancing the bold integrity of thick frames with the lightweight comfort of thin ones, you can create eyewear that truly delivers on its promise.

Frequently Asked Questions

1. Why do my thick acetate frames keep sliding down my nose?

Sliding is usually caused by weight. If a frame weighs more than 30 grams, it can create too much pressure on the nose bridge. The solution is to either choose a lighter material like HDCA or ensure the frame’s design includes large nose pads to better distribute the weight.

2. Is it worth paying more for High-Density Acetate (HDCA)?

Yes, for most modern designs. The material costs 15-25% more, but it creates a frame that is stronger at a lower weight. This directly reduces comfort-related returns and breakage, making it a smart investment in customer satisfaction and brand reputation.

3. Why is Italian acetate considered the best?

Manufacturers like Italy’s Mazzucchelli use a traditional, time-intensive process. They cure the acetate for up to 90 days, which results in richer colors and superior durability. This artisanal approach is why their material is the benchmark for luxury eyewear.

4. Can thin acetate frames handle a strong prescription?

Thin frames work well for prescriptions under ±4.00 diopters. Beyond that, the lens edge becomes too thick to hide effectively. For higher prescriptions, you should always choose a thicker frame (6mm+) to ensure a clean, seamless look.

5. Is it cheaper to manufacture thin or thick frames?

It’s a trade-off. Thin frames use less raw material but require more expensive high-density acetate and precision machinery. Thick frames use more material and require far more manual polishing time. Overall, the costs are surprisingly similar, so the decision should be based on design goals, not perceived savings.