Embellishments on acetate frames fall into three main types. Surface-applied elements, like crystals, are bonded on top of the frame. Integrated embellishments, like metal inlays, are embedded into the acetate for a seamless finish. Finally, subtractive techniques, like laser etching, create texture by removing material from the frame’s surface.

The Strategic Role of Embellishments

Why Embellishments are a Strategic Tool

When developing a new eyewear collection, it’s easy to see embellishments as a final decorative touch. In my two decades in this industry, I’ve learned the most successful brands treat them as a fundamental strategic tool—a calculated decision to solve the problem of creating a generic, forgettable product.

Every detail you add is a business decision that impacts your brand’s story, its perceived value, and its ability to connect with a specific customer. Understanding this allows you to design with purpose, creating eyewear that doesn’t just look good but also performs as a powerful asset for your brand.

Concept: Medical Device to Fashion Accessory

The most important shift in our industry has been eyewear’s evolution from a medical device to a primary fashion accessory. For today’s consumer, glasses are a way to express their personality. This change is a major force behind the global eyewear market’s growth, which is expected to reach an estimated USD 335.90 billion by 2030.

Your customers aren’t just looking for vision correction; they are looking for style and a statement piece. Embellishments are one of the most powerful tools you have to meet this demand, allowing you to infuse a frame with a specific character—be it glamorous, minimalist, or classic—that transforms it from a simple tool into a coveted accessory.

Economic Principle: Justifying a Higher Price

Embellishments have a direct and measurable impact on your product’s bottom line. In an industry where markups can exceed 500% from the production cost, the details you choose are critical in justifying a premium price. Intricate designs and custom hardware signal higher quality and craftsmanship to the consumer.

Simple Analogy: Think of a leather handbag. A plain bag is functional, but one with custom brass hardware and detailed stitching communicates a higher level of design. This perceived value allows a brand to command a higher price. Embellishments on eyewear work in exactly the same way.

Branding Insight: Signature Hardware as a Brand Code

The most strategic brands use embellishments to create a signature—a recognizable visual element that instantly identifies their product. Over time, this signature hardware becomes a powerful brand code, transforming a functional component into a valuable marketing asset that requires no logo to be recognized.

For Example: The iconic gold Medusa head on Versace’s “Medusa Biggie” frames is a perfect case study. That single piece of hardware is so distinctive that it defines the product line. Brands like Native Sons and SALT. also use custom hardware to build immediate brand recognition.

Market Advantage: Visual Differentiation

The global luxury eyewear market is projected to reach over USD 50 billion by 2033, fueled by rising fashion consciousness. In such a competitive environment, visual differentiation is not a luxury; it’s a necessity. Embellishments are your primary tool for carving out a unique space for your brand.

Whether you choose the bold, hand-applied crystals of a brand like Francis Klein or subtle integrated metal details, these choices create a distinct visual identity. This prevents your products from blending in with countless other generic frames, giving customers a clear reason to choose your brand.

Pro Tip: A single, well-placed detail can define an entire product collection. You don’t need to over-design. A custom-shaped rivet or an engraved pattern on the temple core wire, applied consistently, creates a cohesive brand story and makes your collection instantly recognizable.

Defining the Canvas: Frame Anatomy

Before you can decide what embellishment to use, you need to understand where you can apply it. An acetate frame is your canvas, and mastering this basic anatomy is the first step toward making intentional and technically sound decisions. Familiarizing yourself with these professional terms will also help you communicate your vision clearly to manufacturers.

The Temples (Arms): The Largest Area for Branding

The temples are the “arms” of the glasses that rest behind your ears. Because of their length and high visibility from the side, the temples offer the largest surface area for branding and decorative details. This is the prime real estate for telling your brand’s story and is often the most memorable element of the frame.

The End Pieces: Where Function Meets Form

The end pieces are the small parts of the frame front that connect to the temples via the hinges. This area is a perfect example of where a functional component can be transformed into a beautiful design detail. The rivets holding the hinge in place can be a custom shape—like a dot or diamond—that becomes a subtle signature for your brand.

The Frame Front & Rims: Accents to Define Shape

The rims are the parts of the frame that surround the lenses. While the entire frame front can be embellished, small, strategic accents on the rims are particularly effective. Placing a detail here can help to define and accentuate the frame’s overall shape, enhancing its core design without overwhelming it.

For Example: Adding a small cluster of crystals to the upper corner of a cat-eye frame will draw attention to its iconic upswept shape. This is a subtle but powerful way to enhance the frame’s core design.

The Bridge: A Subtle Opportunity for Contrast

The bridge is the part of the frame that arches over the nose. While it’s a less common area for embellishment, it offers a sophisticated opportunity for unique design. Adding a metal bridge to an otherwise all-acetate frame creates a striking material contrast that feels custom and high-end.

A Visual Glossary of Embellishment Techniques

Now that you understand the strategy and the anatomy, let’s move to the “how.” This is your practical guide to the core manufacturing techniques. Your choice of technique directly impacts manufacturing complexity, cost, and durability. This knowledge will help you bridge the gap between a design idea and a manufacturable product.

Category 1: Surface-Applied Embellishments

This category includes techniques where decorative elements are added onto the surface of a finished acetate frame. It’s an additive process, meaning you are bonding a new material to the canvas. This approach is often the most direct way to achieve a look of glamour, luxury, and bold fashion.

Technique: Crystal & Rhinestone Application

This is the classic technique of applying crystals, like those from Swarovski, to the acetate surface for a sparkling, jewel-like effect. For a luxurious look, designers often use a “micro pavé” setting with many tiny crystals set close together. This method is a favorite of high-fashion brands like Dolce & Gabbana and Jimmy Choo.

- Manufacturing Complexity: Low to Medium. The process is primarily manual, requiring skilled hands. It involves careful surface preparation and precise placement of each stone.

- Relative Cost Tier: Low to Medium. The cost is driven by the price of the crystals and the amount of skilled labor time required for application.

- Best For: Brands targeting glamour, luxury, or “maximalist” fashion trends who want to make a bold, eye-catching statement.

Pro Tip: Use multiple crystal sizes (SS5 to SS12) for a more professional, gap-free look. A common mistake is using a single size. To achieve a high-end look, you should specify a range of sizes, typically from SS5 (about 1.8mm) to SS12 (about 3.2mm), to fill all the gaps.

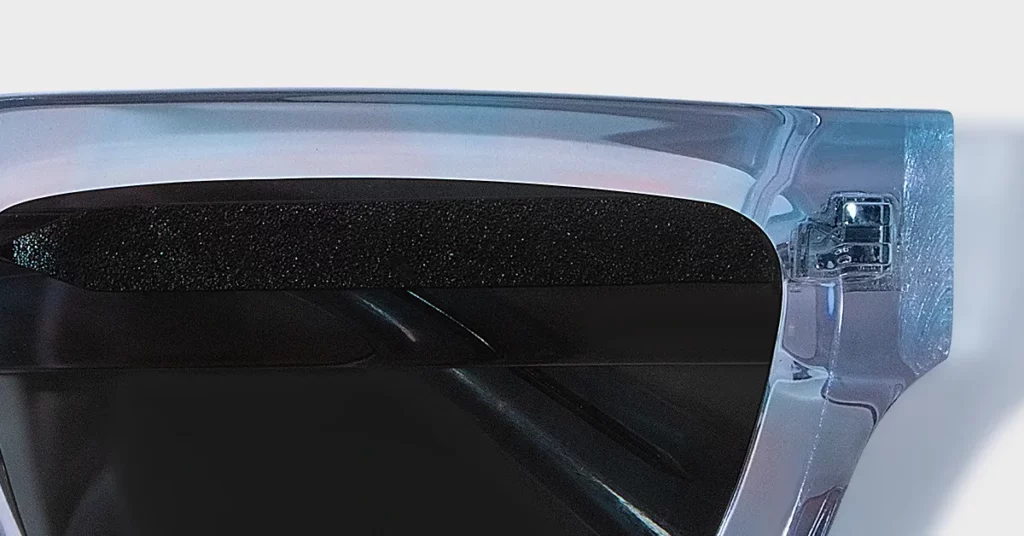

Category 2: Integrated Embellishments

This category represents a more advanced and permanent method. Instead of adding elements to the surface, these techniques physically integrate metal hardware into the acetate material itself. This approach creates a seamless, durable, and distinctly premium feel, signaling a higher level of manufacturing quality.

Technique: Metal Inlays

This technique involves embedding a custom-shaped metal piece into a precisely milled cavity in the acetate, making the metal perfectly flush with the surface. This creates an incredibly sleek look that feels smooth to the touch and signals superior design intent.

A metal inlay is created by embedding a piece of hardware so that it sits perfectly level with the frame’s surface. This means you are physically setting the metal into the acetate, not just gluing it on top. Think of it like a woodworker creating an inlay on a piece of furniture—the two different materials become one seamless, elegant surface.

Definition: Heat or ultrasonic embedding is the industrial process for metal inlays. A specialized machine uses high-frequency vibrations to generate friction between the metal and acetate. This friction creates localized heat, momentarily melting the acetate so the inlay can be pressed into place, locking it in permanently.

- Manufacturing Complexity: High. This technical process requires precision CNC milling, specialized ultrasonic machinery (which can cost from $50,000 to over $500,000), and a skilled operator.

- Relative Cost Tier: High. The cost is driven by the high capital investment in machinery, the need for highly skilled labor, and custom tooling for each inlay design.

- Best For: Luxury and heritage brands that want to communicate quality, permanence, and attention to detail with flush-mounted logos or patterns.

Best Practice: The inlay should be perfectly flush with the acetate surface with no visible gaps. Run your fingertip over the inlay. You should feel a perfectly smooth transition between the metal and the acetate. Any raised edges or visible gaps are signs of poor execution.

Technique: Custom Hardware & Functional Rivets

This technique transforms a necessary component into a key decorative element, most commonly the rivets that secure the hinge. Instead of a standard flat-head rivet, a brand can design its own custom shape—such as dots, diamonds, or shields—that becomes an iconic part of its design language.

A functional rivet is a small metal pin that passes completely through the acetate to physically hold the hinge in place. This means the embellishment is also a structural component, making it incredibly durable. Think of it like the difference between a glued-on button and one sewn through the fabric—the rivet provides a mechanical lock that won’t fail.

Definition: “Custom Hardware Integration” is the strategy of designing, sourcing, and incorporating unique, brand-specific metal components into a frame. It involves creating proprietary hardware that contributes to the brand’s identity.

- Manufacturing Complexity: Medium to High. The process involves precision drilling and peening (flattening) the back of the rivet to secure it, requiring skill to avoid cracking the acetate.

- Relative Cost Tier: Medium to High. The main cost driver is the custom hardware itself, which requires tooling and manufacturing. This is more costly than gluing.

- Best For: Timeless, heritage brands. The use of visible, functional rivets evokes a sense of classic, old-world craftsmanship and durability.

Best Practice: Rivet heads should be smooth, symmetrical, and perfectly finished. When you inspect a frame, look closely at the rivets. They should be polished, free of rough edges, and perfectly symmetrical in their placement.

Technique: Screw-Fastened Hardware

This method is used to attach larger decorative metal pieces, like logo plaques, onto the acetate surface using miniature screws. This provides a very strong and secure mechanical bond, distinct from an adhesive bond or a seamless inlay.

- Manufacturing Complexity: Medium. The primary challenge is precision drilling and tapping (creating threads) in the acetate with very high accuracy to align with the hardware.

- Relative Cost Tier: Medium. The cost is influenced by the manufacturing of the custom hardware and the manual labor required for assembly.

- Best For: Attaching larger, custom-designed metal pieces that require maximum durability and will remain secure through years of daily wear.

Best Practice: Screws should be flush, secure, and made of a corrosion-resistant metal. Inspect the finished product to ensure the screw heads sit flush with the hardware’s surface and are tight. Confirm with your manufacturer that the screws are stainless steel to prevent corrosion.

Category 3: Subtractive Embellishments

The final category is unique because it doesn’t add any new material. Instead, these techniques create a decorative effect by precisely removing or altering the surface of the acetate itself. This approach is perfect for creating subtle textures, intricate patterns, and a modern, material-focused aesthetic.

Technique: Laser Etching & Engraving

This technique uses a computer-controlled laser beam to etch a design directly onto the acetate surface. The laser vaporizes a thin layer of material, creating a permanent mark with incredibly fine details. This results in a “carved effect” that feels both technical and artisanal.

- Manufacturing Complexity: Medium. The process requires a CO2 laser system and expertise to properly calibrate the laser’s power and speed to avoid burning the acetate.

- Relative Cost Tier: Low to Medium. The primary expense is the laser machine. Once set up, the cost per unit is relatively low as the process is fast and highly automated.

- Best For: Creating subtle, intricate patterns, micro-branding, or a textured feel. It is perfect for brands with a minimalist or modern aesthetic.

Pro Tip: This technique works best with solid-colored acetate to maximize contrast. The effect is a subtle, tonal change. On a busy, multi-colored pattern like tortoiseshell, a delicate laser-etched design can easily get lost.

| Feature | Crystal Application (Surface) | Metal Inlay (Integrated) | Laser Etching (Subtractive) |

| Manufacturing | Low to Medium (Labor-intensive) | High (Requires specialized machinery) | Medium (Requires calibration) |

| Relative Cost | Low to Medium | High | Low to Medium |

| Durability | Medium (Risk of stones falling off) | High (Permanent, integrated) | High (Part of the material) |

| Aesthetic | Glamorous, Bold, Maximalist | Seamless, Premium, Understated | Subtle, Textural, Intricate |

| Best For | Fashion-forward, Trend-driven | Luxury, Heritage, Timeless | Minimalist, Modern, Tech-focused |

The Bottom Line: Your choice of technique sends a clear message about your brand. Surface applications shout glamour and fashion, integrated hardware whispers timeless quality and craftsmanship, and subtractive methods signal modern, minimalist sophistication.

From CAD to Creation: Key Considerations

Material Science for the Designer

A foundational understanding of your materials is non-negotiable. Your ability to specify the right materials separates a professional design from an amateur one. This knowledge ensures your final product is not only beautiful but also durable, comfortable, and of high quality.

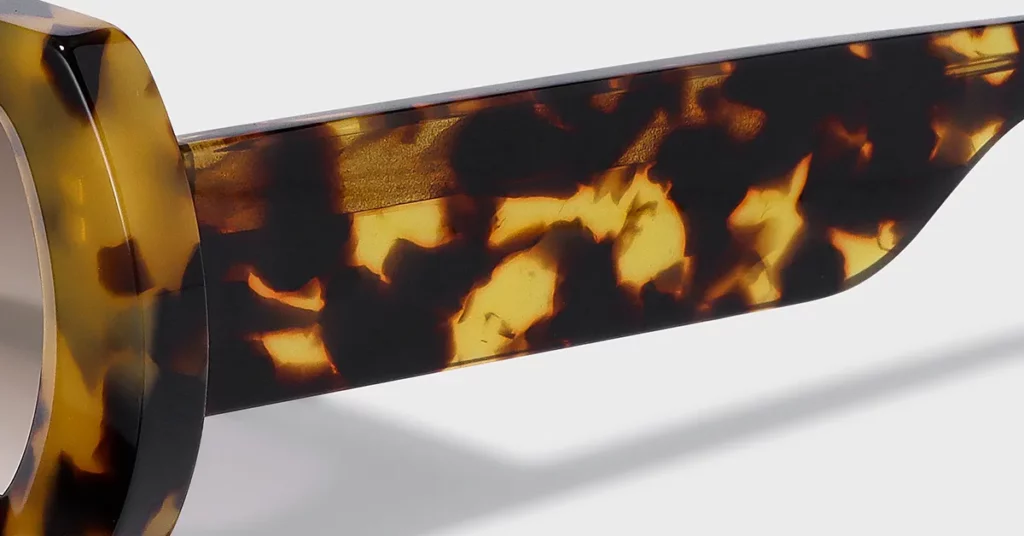

Why Premium Cellulose Acetate is the Ideal Canvas

Not all “plastic” frames are equal. Premium brands choose cellulose acetate because it’s a plant-based bioplastic derived from cotton and wood pulp. This makes it stronger, more flexible, and more durable than standard injection-molded plastic. Carved from layered blocks, it allows for incredibly rich and deep colors that won’t peel or fade.

Choosing the Right Metal for Your Hardware

The metal you choose for rivets, inlays, and screws directly impacts the frame’s durability and hypoallergenic properties.

- Stainless Steel: A top-tier choice. It is extremely strong, highly resistant to corrosion, and generally hypoallergenic, making it safe for skin contact.

- Nickel Silver: A copper alloy with nickel and zinc. Its nickel content means it is not hypoallergenic and can cause skin irritation, so it must be coated with a protective plating.

- Plated Alloys: A cost-effective option where a base metal (like Monel) is coated. Quality varies dramatically; a low-quality plating can wear away, exposing the base metal.

Understanding Professional Adhesives

When bonding embellishments, the adhesive is critical to longevity. Consumer craft glues are not sufficient for a commercial product.

- Epoxy Resins: These are industrial-strength, two-part adhesives that create an incredibly strong, durable, and permanent structural bond. They are the professional choice for bonding metal or crystals to acetate.

- Gem Glues: This category includes cyanoacrylate (“super glue”), which forms a brittle bond that can crack on flexible acetate. Water-based “tacky” glues are flexible but lack the industrial-grade strength of epoxy.

The Importance of Surface Preparation

Adhesives struggle to bond to a perfectly smooth, glossy surface. To ensure a permanent bond, the area where the embellishment will be placed must first be lightly abraded or sanded.

Proper surface preparation creates a microscopic, rough texture known as a “key.” This means you are intentionally scratching the polished surface so the glue has something to grab onto. Think of it like trying to climb a smooth, glass wall versus a brick wall—the rough texture of the bricks gives you handholds, creating a much stronger connection.

The Value of Italian Acetate

Where your acetate comes from matters. For decades, Italian acetate—particularly from the manufacturer Mazzucchelli—has been the global benchmark for quality. Specifying “Mazzucchelli acetate” in your tech pack is a clear way to signal your commitment to using the highest quality materials available.

The Designer’s Checklist: Form vs. Function

A successful eyewear design is a masterclass in balancing aesthetics with functionality. An embellished frame that is beautiful but uncomfortable or easily broken is a failed design. Before you finalize your concept, you must run it through a checklist of these real-world constraints.

1. The Impact of Added Weight on Comfort

Every element you add contributes to the frame’s total weight and affects its balance on the wearer’s face. A heavy metal plaque or a dense application of crystals can cause the frames to constantly slide down the nose or put uncomfortable pressure on the bridge.

Best Practice: Always consider the weight of your embellishments. If you are adding a significant detail to the temples, you may need to ensure the frame front has enough weight to act as a counterbalance. The goal is a frame that feels secure for all-day wear.

2. Allowing for Temple Adjustments

This is one of the most critical and frequently overlooked functional constraints. Acetate frames are designed to be adjusted by an optician for a custom fit. This process involves gently heating the temple arms to make them pliable, then bending them to conform behind the wearer’s ear.

Critical Warning: This adjustment happens on the final third of the temple arm. If you place a large, rigid embellishment in this “adjustment zone,” you make it impossible for the optician to perform their job. The frame becomes un-fittable, leading to a poor customer experience.

3. Durability for Daily Wear and Tear

Your design must be robust enough to withstand the realities of daily life. The embellishments, and the methods used to attach them, must be specified for longevity. An industrial-grade epoxy will provide a far more durable bond than craft glue, and a functional rivet provides a mechanical lock that is superior to a surface-bonded detail.

4. Manufacturing Tolerances and Feasibility

What looks perfect in a 3D CAD rendering may be prohibitively expensive to produce consistently at scale. You must design with manufacturing tolerances in mind. A metal inlay requires a precise fit, but not one so tight that it can’t be consistently assembled in a factory setting.

Best Practice: This is where early collaboration with your manufacturing partner is invaluable. They can provide feedback on your design’s feasibility and help you define realistic tolerances that ensure a high-quality result without a high defect rate.

5. Repairability: Planning for Accidents

While you should design for durability, it’s wise to consider the entire lifecycle of the product. Accidents happen. Can replacement crystals be sourced and applied by an optician? Is screw-fastened hardware a standard size? Planning for these scenarios shows a commitment to customer service and builds brand loyalty.

Avoiding Amateur Mistakes: A Checklist

Mistake #1: The Embellishment Fights the Frame Shape

A great design feels cohesive, where every element works in harmony. When an embellishment “fights” the frame, it looks like a tacked-on afterthought and cheapens the entire product. The shape, scale, and flow of your embellishment should echo or accentuate the silhouette of the frame.

Pro Tip: Print a 1:1 scale drawing of the frame to sketch ideas directly on paper first. This simple method gives you an immediate and intuitive feel for the scale and flow of the design, helping you spot potential aesthetic conflicts early.

Mistake #2: A Design That Is Too Complex or Costly

This is the classic gap between a creative vision and the reality of production. A stunning design might require manufacturing techniques that are either too expensive or beyond your partner’s capabilities. Always consult with your manufacturing partner early in the design process.

Remember This: When choosing a technique, you must balance cost, complexity, and the final look. Gluing is low-cost for fast-fashion. Riveting is mid-cost for a durable, heritage feel. Inlaying is high-cost for a premium, seamless finish.

Mistake #3: Using the Wrong Adhesive

For any design that involves surface-applied elements, the choice of adhesive is a critical point of potential failure. Using a cheap, consumer-grade glue is a recipe for disaster, leading to embellishments falling off, angry customers, and costly warranty claims.

Common Mistake: Many people assume “super glue” (cyanoacrylate) is the strongest option. This is incorrect for eyewear. Cyanoacrylate creates a rigid and brittle bond. Because acetate is flexible, this bond will crack and fail. A professional-grade epoxy is required.

Remember This: Adhesives need “cure time” to reach maximum strength. Rushing this step results in a weak bond. A full, proper cure for industrial epoxies can take several hours, so it’s best practice to let them set overnight for maximum durability.

Mistake #4: Forgetting About Frame Adjustments

This is the ultimate functional mistake that can render a beautiful design useless. It stems from forgetting that an eyewear frame is a medical device that must be professionally fitted. Placing a large, rigid embellishment along the entire temple makes this impossible.

The Bottom Line: You must keep rigid embellishments clear of the final third of the temple arm. This is a non-negotiable rule of professional eyewear design. This single consideration will ensure your beautiful designs are also functional, wearable, and respected by the professionals who sell them.

Conclusion

To create truly exceptional eyewear, you must treat embellishments as a strategic business decision, not just decoration. A successful design always balances your creative vision with the realities of manufacturing and the functional needs of the wearer. By mastering these professional techniques and avoiding common mistakes like blocking the temple adjustment zone, you can create products that add tangible value and build a powerful, lasting brand.

Frequently Asked Questions

1. What is the most durable type of embellishment?

Integrated embellishments are the most durable. Techniques like functional rivets or ultrasonic metal inlays create a permanent, mechanical bond, making them part of the frame’s structure and highly unlikely to detach.

2. How much cost does custom hardware add to a frame?

The cost varies widely but is a significant factor. It can add anywhere from a few dollars to over twenty dollars to the unit cost, as it requires investment in tooling and uses more expensive materials than acetate alone.

3. Can embellished frames be adjusted for fit?

Yes, but only if designed correctly. An optician must be able to heat and bend the final third of the temple arm. Any large, rigid embellishments must be kept clear of this “adjustment zone” to allow for proper fitting.

4. What’s the difference between a cheap and premium embellished frame?

The difference is the quality of materials and technique. A premium frame uses high-grade Italian acetate, corrosion-resistant metals, and professional methods like riveting. A cheaper frame uses lower-grade plastic with surface-glued embellishments prone to falling off.

5. How do I communicate my embellishment idea to a manufacturer?

Use a comprehensive technical package (“tech pack”). This must include detailed, to-scale drawings (CAD files) with precise measurements and specifications for all materials (e.g., “stainless steel,” “Mazzucchelli acetate”) and the exact manufacturing technique required.