As a brand manager or designer, you constantly hear “Mazzucchelli acetate” used as the benchmark for premium eyewear. But what does that really mean for your product and your story? This guide is your exclusive, behind-the-scenes tour. We will move past the marketing buzzwords and break down the entire artisanal process, from raw cotton pulp to a polished luxury good, giving you the expert knowledge to choose and communicate your materials with total confidence.

Mazzucchelli acetate is a premium, plant-based bioplastic crafted from cotton and wood pulp. Its unique manufacturing process involves casting colored acetate dough into solid blocks, which are then cured for several weeks. This time-intensive method creates an unmatched depth of color, pattern complexity, and long-term durability that is impossible to achieve with standard, petroleum-based injection-molded plastics.

What Is Mazzucchelli Acetate & Why It Matters

Defining Premium: More Than Just Plastic

First, understand that while cellulose acetate is a type of plastic, comparing it to the cheap, petroleum-based plastic in mass-market frames is like comparing a hand-stitched leather shoe to a vinyl flip-flop. Their origins, creation, and performance are worlds apart. They simply aren’t in the same category.

Definition: Cellulose acetate is a plant-based bioplastic, meaning its core ingredient comes from nature, not petroleum. This is the fundamental difference that dictates its quality, feel, and sustainability profile. In the industry, you’ll often hear it called by its traditional name, zyl or zylonite.

This premium material is derived from purified cellulose, a natural polymer from renewable resources like cotton linters (the fine fibers on cotton seeds) and responsibly managed, FSC-certified wood pulp. This natural origin is key to the material’s superior feel and performance.

The core difference lies in how frames are made. Standard plastic frames are produced through injection molding—a fast, additive process. In contrast, premium acetate frames are made through a subtractive process. We start with a solid block of acetate and use precision machinery to carve the frame components out of it, preserving the material’s integrity.

You need to understand that the difference between subtractive and additive manufacturing is fundamental to quality. Additive injection molding is fast and cheap, building a frame layer by layer. Think of it like using a 3D printer. The subtractive method, however, is like a sculptor carving from a block of marble—it reveals the inherent beauty within the material, resulting in superior strength and pattern continuity.

Because it’s derived from natural sources, Mazzucchelli acetate is hypoallergenic and biocompatible. It is rigorously tested to ensure it is safe for prolonged skin contact. This translates to a more comfortable experience for your customers, eliminating the risk of irritation common with cheaper materials.

The Mazzucchelli Benchmark: A Legacy of Craft

To understand premium acetate, you have to understand the company that perfected it. Mazzucchelli 1849 is a sixth-generation, family-owned Italian company that is the gold standard in acetate production. For over 175 years, they have been the undisputed leader and innovator in the field.

The company’s journey began in 1849, when founder Santino Mazzucchelli crafted combs from natural materials like animal horn and tortoiseshell. This expertise in organic materials provided the foundation for their evolution. As technology advanced, the family pioneered the use of celluloid and, in 1936, transitioned to cellulose acetate, becoming a world leader.

This “Made in Italy” heritage represents a culture of artistry, meticulous attention to detail, and generational knowledge. This is why the world’s most respected luxury eyewear brands, from Linda Farrow to Oliver Peoples, exclusively use Mazzucchelli acetate. They are investing in a guarantee of quality and a story of authentic craftsmanship.

Pro Tip: For a new brand, specifying Mazzucchelli acetate is a powerful strategic tool. It works as “ingredient branding,” much like “Intel Inside” for computers. It instantly signals quality, justifies a premium price point, and leverages a 175-year-old legacy to build trust in your own products.

The Core Ingredients of Mazzucchelli Acetate

To appreciate the final product, you need to understand the three fundamental components that create a sheet of Mazzucchelli acetate. Each ingredient plays a critical role in the material’s performance, beauty, and sustainability.

The Foundation: Starting with Natural Cellulose

The process begins with cellulose, the most abundant organic polymer on Earth. It is the structural component of plant cell walls and provides the core strength of the final acetate material. Mazzucchelli sources its cellulose in its purest form from two key renewable sources: cotton linters and wood pulp.

Best Practice: The wood pulp is sourced from forests certified by the Forest Stewardship Council (FSC). This ensures raw materials come from responsibly managed forests. This allows you to build a powerful and verifiable sustainability story for your brand, right from the source.

The Enabler: Bio-Based Plasticizers

Pure cellulose is rigid. To give it the flexibility and toughness needed for eyewear, it must be mixed with agents called plasticizers. While the industry standard was petroleum-based plasticizers, Mazzucchelli’s commitment to innovation led to a breakthrough.

Through extensive R&D, Mazzucchelli created M49®, a revolutionary bioplastic. In this patented formula, the traditional plasticizer is replaced with a proprietary solution from vegetable origins. This eco-innovation dramatically increases the material’s bio-based content, making it a more environmentally conscious product.

The Bottom Line: The result is a material that delivers premium durability while also being biodegradable. This solves a core challenge for modern brands: you can offer a product that is both exceptionally high-quality and authentically sustainable, without compromise.

The Soul: Artisanal Pigments & Dyes

The soul of Mazzucchelli acetate—its incredible color and pattern—comes from how it is colored. The process uses finely ground organic powdered pigments, which are meticulously mixed into the raw acetate paste. The color is an integral part of the material itself, not just a surface coating.

This method results in a depth and vibrancy that is second to none. The colors are embedded within the acetate, meaning they will never fade or peel. This technique allows for a richness and complexity that cannot be replicated with surface-level coloration. This mastery of color has allowed Mazzucchelli to build a historical archive of more than 25,000 different colors and patterns.

The Making of a Mazzucchelli Sheet: A Step-by-Step Journey

Now that you understand the ingredients, let’s walk through the life story of a single sheet of acetate. This is where science transforms into art, and raw materials are imbued with the quality that defines the Mazzucchelli name.

Step 1: Creating the Acetate “Dough”

The journey begins when the purified natural cellulose is mixed with acetic acid, solvents, and the bio-based plasticizers in large industrial mixers. This chemical reaction, acetylation, transforms the raw pulp into a thick, malleable, and transparent paste—the base material for everything that follows.

This is the moment of creation for color. The finely ground powdered pigments are added to the transparent paste. To ensure a perfectly uniform color, this “dough” is then passed through large rollers repeatedly. This intensive blending process is what gives the final material its flawless, homogenous color.

The Bottom Line: This initial, thorough mixing is a critical quality control step. It ensures a consistent color base and prevents any streaks or imperfections in the final product, guaranteeing every frame cut from the block is perfect.

Step 2: Building Color & Pattern into Blocks

Once the colored dough is mixed, it is placed into large molds and pressed under immense pressure. This process, known as block-casting, forms a solid, dense block of acetate completely free of air bubbles. This is the fundamental method that separates premium acetate from cheaper alternatives.

To create Mazzucchelli’s world-famous patterns, artisans employ incredible skill:

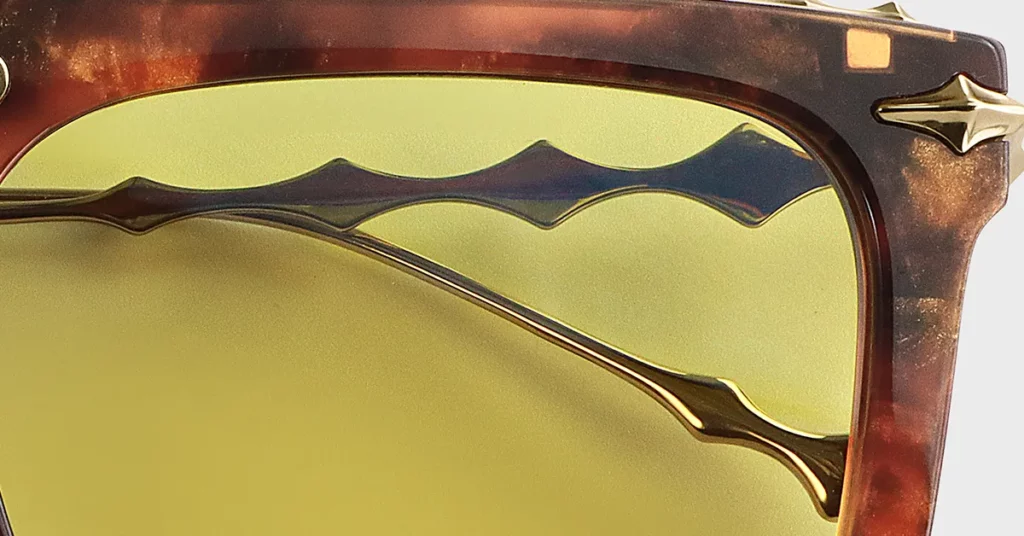

- The Tortoiseshell Technique: To achieve an iconic “Havana” pattern, solid blocks of different colors are cured, then chipped into small pellets. These colored chips are artfully arranged in a new mold and pressed again, fusing them into a new, multi-colored block with a stunning three-dimensional pattern.

- The Layering Method: For other designs, entire blocks of different colors are sliced into sheets, which are then layered. These layers are fused together with heat and pressure to create intricate, 3D patterns that run through the entire depth of the new block.

You need to understand that block-casting is the only way to achieve true pattern depth. While cheaper methods might print a pattern on the surface, block-casting builds it right into the material’s core. Think of it like the difference between a wood veneer and a piece of solid oak—one is a thin surface layer, while the other has grain and character running all the way through.

Step 3: The Critical Weeks-Long Curing Process

This next stage is perhaps the most critical step, and it’s the one most often skipped by low-cost producers. The solid, patterned blocks of acetate are moved into special ovens where they are left to “season” or cure for several weeks.

The science behind this is vital. The slow, gentle heat allows any residual solvents to slowly and completely evaporate. This stabilizes the acetate from the inside out, ensuring all its components are perfectly bonded. Rushing this step is simply not an option if you want to achieve a premium, stable material.

Simple Analogy: Think of it like aging a fine wine or a wheel of Parmesan cheese. Time is the most important ingredient. It develops complexity and ensures a stable, high-quality final product. This long, costly process is the secret to the material’s exceptional stability and durability.

The Bottom Line: Curing prevents future warping, shrinkage, and brittleness, and it permanently locks in the vibrancy of the pigments. For your brand, this step is a direct investment in the longevity of your product and the satisfaction of your customers.

Step 4: Slicing and Stabilizing the Final Sheets

After the long curing process, the seasoned blocks are moved to a slicing machine, where a large blade shaves the block into individual sheets of a specific thickness. This thickness can be precisely controlled, giving you, the designer, incredible flexibility for different applications and styles.

Finally, these freshly cut sheets are hung on large racks and placed in ovens for one last heat stabilization. This final step ensures the sheets are completely inert and will hold their shape perfectly through the next stages of manufacturing and for the lifetime of the product.

The Bottom Line: The final stabilization process guarantees dimensional stability. It ensures the acetate sheet will not warp or change shape when it is later milled into a frame, guaranteeing a consistent and reliable product for your customers.

From Sheet to Style: Crafting a Luxury Frame

Mazzucchelli’s role is to create the perfect raw material. The next stage involves turning that beautiful sheet into a finished, wearable piece of luxury eyewear. Understanding this final part of the journey helps you appreciate the full craftsmanship involved.

CNC Milling: Carving the Frame Components

The process of creating the frame parts begins with a Computer Numerical Control (CNC) machine. Following a precise digital design, the machine’s cutting tool carves the frame fronts and temples directly from the acetate sheets.

This reinforces the core difference between premium and mass-market eyewear. Unlike injection molding, an additive process of building up a shape, this is a subtractive process of carving away material to reveal the form within. This is what preserves the integrity of the acetate’s internal pattern.

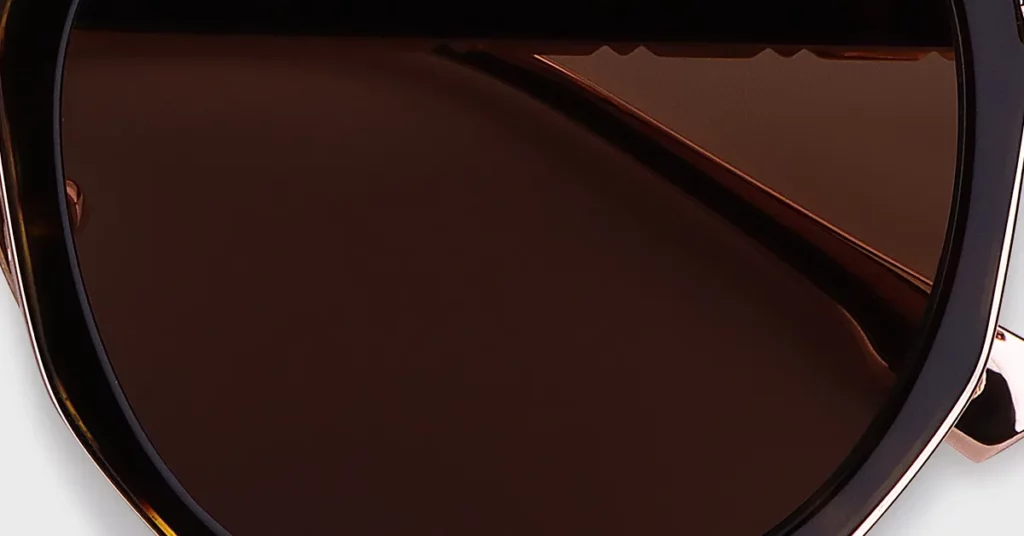

Pro Tip: Because the frame is cut from a solid, patterned block, the beautiful colors and layers flow seamlessly and organically around the curves of the frame. This creates a look of depth and authenticity that simply can’t be faked with surface-level printing.

The Final Polish: Tumbling and Hand-Buffing

After the parts are cut, they are still rough. To achieve their final, lustrous finish, they undergo a multi-stage polishing process. First, the parts are placed in large barrels filled with wood chips and polishing compounds. These barrels tumble for several days, allowing gentle abrasion to smooth out all rough edges.

After tumbling, the human touch comes in. Skilled artisans take each component and hand-polish it on buffing wheels. This meticulous process is what brings out the deep, high gloss that is the hallmark of premium acetate. The result is a seamless, smooth surface with a characteristic warm and silky feel, a clear sign of quality.

Adding Strength: Inserting the Metal Wire Core

The final structural step is one of the most important for function and fit. A heated metal wire core is “shot” directly into the center of each acetate temple (or “arm”). This metal core serves two critical purposes: it provides essential rigidity and strength, and most importantly, it enables adjustability.

You need to understand that the metal core is the key to a custom fit. The metal allows an optician to gently heat the temples and bend them to perfectly match the wearer’s unique head shape. Think of it like the hidden steel frame inside a sculpture—it provides the unseen strength and structure that allows for the final, perfect form.

The Bottom Line: Frames without this internal metal core can never be properly adjusted. The presence of this feature is a clear and immediate sign of higher-quality construction and a commitment to customer comfort.

Your Strategic Guide: Turning Process into Value

Understanding the “how” is only the first step. As a brand manager, your job is to translate these technical processes into real brand value. Here is a simple guide to help you communicate the premium nature of Mazzucchelli acetate to stakeholders and customers.

Justifying the Premium Cost to Your Stakeholders

When you choose a premium material, you need to confidently explain why it’s worth the investment. Here are four powerful stories rooted in the manufacturing process:

- The Story of Time: The most compelling justification is the time involved. Explain that each block is seasoned for weeks, a crucial step that cheaper materials skip. This process is a direct investment in a product that won’t warp or become brittle.

- The Story of Artistry: Emphasize the human touch. The iconic patterns aren’t automated; they are created by skilled artisans who artfully combine colored chips and layers by hand. This is true craftsmanship, not mass production.

- The Story of Quality: Connect the curing process directly to customer satisfaction. This step ensures the material is stable, strong, and durable. It’s the reason the frames will last for years, which prevents costly returns and builds brand loyalty.

- The Story of Sustainability: Lead with the plant-based origins. The material is made from renewable cotton and wood, not fossil fuels. With innovations like M49, you can tell a story of biodegradability, offering a truly responsible luxury product.

Key Metric: The premium eyewear market is increasingly driven by sustainability, with over 22% of new products in 2024 featuring eco-friendly materials. This is a story that matters to a growing segment of consumers.

Crafting a Compelling Product Story

Use the details of the manufacturing process to build a richer, more authentic narrative. Move beyond generic terms like “high-quality” and use specific, evocative language.

- Focus on Heritage: Leverage the Mazzucchelli legacy. “Our frames are crafted from acetate made by a sixth-generation family of Italian artisans who have been perfecting their craft since 1849.”

- Focus on Aesthetics: Highlight the unmatched color depth. “The rich color isn’t a surface coating; it’s embedded deep within the material, creating a vibrancy that will never fade.”

- Focus on Feel: Emphasize the unique tactile experience. “Made from natural cotton fibers, our frames have a warm, silky feel against the skin—a clear departure from the cold feel of petroleum-based plastic.”

- Focus on Durability: Explain how the process creates a long-lasting product. “Every sheet is seasoned for weeks to ensure your frames hold their shape perfectly, providing a comfortable and reliable fit for years to come.”

Conclusion

Understanding the journey from pulp to polish does more than build your technical knowledge; it equips you with the story of true craftsmanship. You can now see that the value of Mazzucchelli acetate isn’t just in the material, but in the time, artistry, and innovation embedded within it. By choosing this material, you are ensuring a superior product and inheriting a powerful narrative of quality that will elevate your brand. At Kssmi, we partner with brands like yours to navigate these choices, ensuring every material decision aligns perfectly with your vision.

Frequently Asked Questions

1. Is Mazzucchelli acetate really better than other acetates?

Yes. While other high-quality producers exist, Mazzucchelli’s combination of a 175-year heritage, unparalleled color artistry, massive scale, and industry-leading R&D (like M49 bioplastic) firmly establishes it as the global benchmark for premium cellulose acetate.

2. Why are some acetate frames so much more expensive than others?

The cost reflects time, skill, and raw material quality. The multi-week curing process, skilled labor for pattern creation, premium bio-based plasticizers, and higher material waste from carving frames (versus injecting them) all contribute to the higher cost and superior quality.

3. Can you tell the difference between acetate and cheap plastic just by looking?

Often, yes. Look for signs of quality: a deep, lustrous polish, rich colors that show dimensionality, and seamless patterns that flow around the frame’s curves. Premium acetate also feels denser, smoother, and warmer to the touch.

4. Is acetate a sustainable or “eco-friendly” material?

It is fundamentally more sustainable than petroleum-based plastics because its core ingredient, cellulose, is a renewable, plant-based resource. Innovations like Mazzucchelli’s M49, which uses vegetable-based plasticizers, make the material biodegradable, placing it among the most responsible material choices.

5. How does the manufacturing process affect the durability of the final glasses?

Every key step is designed for durability. The long curing process prevents warping and brittleness. The final heat stabilization ensures the material holds its shape. And the insertion of a metal core into the temples provides the necessary strength for a long-lasting, adjustable frame.