Choosing the right materials for your eyewear can feel overwhelming. You might know the difference between acetate and titanium for a frame front, but what about the hinges, the screws, or the tiny wire inside the temple? Making a mistake on these small components can lead to product failure, unhappy customers, and damage to your brand’s reputation. This guide moves beyond the basics, giving you a component-by-component framework to make informed decisions for every single part of your product.

A premium pair of glasses is an assembly of up to 13 distinct parts, each requiring specific materials to ensure quality, comfort, and longevity. True product excellence is achieved by selecting the right material for each component, from the frame front down to the screws, creating a final product that is far greater than the sum of its parts.

The Anatomy of Premium Eyewear: A 13-Part Breakdown

An Exploded View of a Well-Made Frame

A complete pair of glasses is an assembly of many distinct components, each demanding specific material properties to create a high-quality product. To truly engineer superior eyewear, you must understand how these parts work together across three functional zones:

- The Frame Front: This is the primary aesthetic zone, including the rims, bridge, and end pieces. It’s responsible for holding the lenses and defining the style.

- The Temples: This zone ensures a secure, comfortable fit and includes the temple arms, core wires, and temple tips.

- The Hardware: These are the mechanical workhorses that provide functionality and adjustability, comprising the hinges, screws, pad arms, and nose pads.

Most Importantly: Specifying materials at the component level is what separates premium eyewear from mass-market products. A brand that specifies high-grade titanium for its pad arms and nylon-coated screws can prevent common failures, reduce returns, and justify a premium price. With the global eyewear market projected to reach USD 335.90 billion by 2030, this granular knowledge is a significant competitive advantage.

Best Practice: This guide is structured to help you build a superior technical pack (tech pack)—the blueprint you send to your manufacturer. Instead of writing “metal hinge,” a professional tech pack specifies “5-barrel stainless steel hinge.” Using this guide will provide the specific data you need to reduce ambiguity and prototyping errors.

1. The Rim (or Eyewire): The Foundation of Style and Structure

The Common Problem: Rims That Feel Flimsy or Crack Under Stress

A common failure in low-quality frames is a weak rim that allows lenses to pop out or develops stress fractures when prescription lenses are inserted. In cheap plastics, this can lead to cloudy discoloration, while low-grade metals can corrode at the weld points connecting the rim to the bridge, leading to total frame failure. This is a direct result of poor material selection.

Function: Securing the Lens and Defining the Aesthetic

Definition: The rims, also called eyewires, perform two primary functions: they securely hold the lenses under constant tension and define the overall shape and character of the eyeglasses. The rim is the main structural chassis of the frame front, and its material integrity is paramount to the product’s longevity. The material and thickness of the rim are also key aesthetic communicators, with thin titanium conveying minimalism and thick acetate making a bold statement.

Premium Material Options for Rims

For premium frames, you have several excellent material choices, each with distinct benefits:

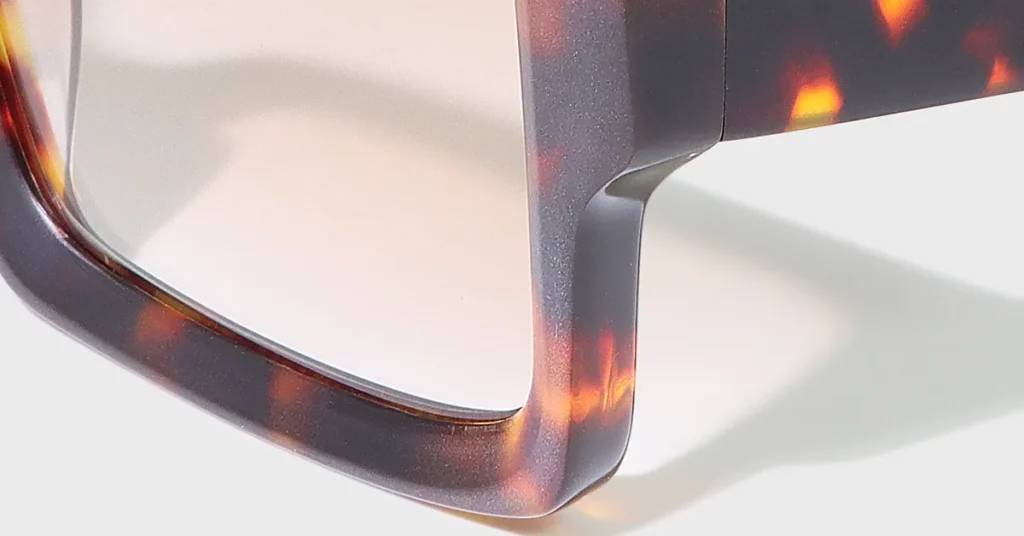

- Mazzucchelli Acetate: The industry gold standard for unparalleled color and depth. This plant-based plastic is hypoallergenic, renewable, and allows for rich, layered patterns impossible with other plastics.

- Bio-Acetate: A sustainable option that uses vegetable-based plasticizers, making it biodegradable. Suppliers like Mazzucchelli (M49) offer materials with up to 68% bio-based content.

- Titanium (Pure & Beta): A premium metal known for its high strength-to-weight ratio, corrosion resistance, and hypoallergenic properties. Beta titanium, an alloy, offers more flexibility for thinner designs.

- Stainless Steel: A strong, lightweight, and corrosion-resistant metal that provides a sleek, modern look at a more accessible price point than titanium.

- Carbon Fiber: Offers an unparalleled strength-to-weight ratio for a high-tech, performance aesthetic. However, its rigidity makes it difficult to adjust, and manufacturing is complex.

- TR90: A thermoplastic with “shape memory”, allowing it to bend under pressure and return to its original form. This makes it incredibly durable and ideal for sports or children’s eyewear.

2. The Bridge: Comfort, Fit, and Structural Integrity

The Common Problem: Frames That Slide Down the Nose or Leave Red Marks

A poorly designed bridge is the main cause of discomfort and slippage. It fails to properly distribute the frame’s weight, creating pressure points. This is often the result of a mismatch between the bridge design and the wearer’s anatomy, a problem that a “one-size-fits-all” approach cannot solve in premium eyewear, which must serve a global market with diverse facial structures.

Function: Connecting the Rims and Distributing Weight

Definition: The bridge is the component that connects the two rims and rests on the wearer’s nose, supporting the majority of the frame’s weight. The design of the bridge is the most critical factor in determining the overall comfort and fit of a pair of glasses.

Simple Analogy: Think of the bridge as the suspension of the frame. Just as a car’s suspension absorbs shock and ensures a smooth ride, the bridge of a frame absorbs and distributes weight for comfortable, all-day wear.

Premium Material & Design Options

- Saddle Bridge (Acetate): A smooth, curved design sculpted directly into an acetate frame. This design spreads weight evenly across a larger surface area of the nose, eliminating pressure points.

- Keyhole Bridge (Acetate): A design shaped like a keyhole that rests on the sides of the nose rather than the top. This provides a specific fit for certain nose shapes and offers a classic, vintage aesthetic.

- Metal Pad Arm Bridge (Titanium/Steel): A design that uses adjustable arms to hold separate nose pads. This allows an optician to precisely customize the fit for any nose shape, offering maximum adjustability.

3. The End Piece: The Critical Connection Point

The Common Problem: Hinges That Loosen or Break Away from the Frame Front

When a hinge breaks off the frame front, the failure is often not in the hinge itself but in the end piece where the hinge is mounted. This area is a high-stress fulcrum point that bears significant mechanical stress. If the end piece is too thin or made of weak material, it cannot provide a secure anchor for the hinge, leading to breakage.

Function: Linking the Frame Front to the Hinge

Definition: The end pieces are the small parts on the frame that extend outward from the rims and serve as the mounting point to connect the temples via the hinges. The repeated action of folding and unfolding the temples places immense torsional and tensile stress directly on the end piece.

Pro Tip: When evaluating a frame’s quality, inspect the end piece. In acetate frames, it should be thick and substantial enough to securely embed the hinge. In metal frames, the weld or solder joint connecting the hinge should be clean and robust, with a large surface area for a strong bond.

4. The Hinge: The Engine of the Eyewear

The Common Problem: Hinges That Seize Up, Turn Green, or Feel Flimsy

Low-quality hinges corrode, loosen, or break prematurely. This is a direct result of using inferior materials like nickel-based alloys and insufficient barrel construction. Sweat is saline and acidic, which causes galvanic corrosion in these alloys, appearing as a green or white residue that can cause the hinge to seize or break.

Function: Allowing the Temples to Fold Securely

Definition: Hinges are the mechanical joints that connect the end pieces to the temples, allowing the temples to fold inward for storage. The tactile experience of opening and closing the temples is a key indicator of quality.

Simple Analogy: A premium hinge is like a luxury car door—smooth, silent, and built to last. While the ISO 12870 standard requires a 500-cycle endurance test, premium manufacturers often test their hinges for 20,000 cycles or more to ensure long-term durability.

Hinge Construction Types: A Comparative Analysis

- Standard Barrel Hinge (3, 5, or 7 barrels): This robust workhorse consists of interlocking barrels held together by a screw. More barrels equal greater stability. A 5-barrel hinge is the standard for quality, while a 7-barrel hinge offers maximum strength.

- Spring (Flex) Hinge: This design contains a small spring that allows temples to flex outward beyond 90 degrees, providing a more secure fit and resistance to damage. However, it is more complex to repair if the spring fails.

- Embedded (Hidden) Hinge: In this high-end design, the hinge mechanism is concealed within the acetate, creating a seamless exterior line. This requires precise milling and is a marker of superior craftsmanship.

Premium Material Options for Hinges

- Nickel Silver: The industry standard alloy of copper, nickel, and zinc. It is cost-effective but can cause allergic reactions and is prone to corrosion.

- Stainless Steel: A superior choice offering excellent strength and high resistance to corrosion. It is also generally hypoallergenic.

- Titanium: The premium option, offering the best combination of strength, low weight, corrosion resistance, and biocompatibility. It is 100% hypoallergenic.

5. The Screw: The Smallest Part with the Biggest Job

The Common Problem: Screws That Constantly Loosen and Fall Out

The single most frequent point of failure in eyewear is a lost hinge screw, which renders the glasses unusable. This preventable issue is caused by using basic, uncoated screws that inevitably loosen over time due to the vibration and micro-movements of the hinge. This gradual backing out is known as “screw creep.”

Function: Acting as the Pivot and Fastener for the Hinge

Definition: The hinge screw acts as the axle pin that holds the interlocking barrels of the hinge together, allowing the temple to pivot. A single loose screw can render a pair of glasses unusable.

Simple Analogy: The screw is the linchpin holding the entire system together. Like the pin on a wheel, this tiny component is all that prevents the structure from falling apart. This is why a simple component deserves a premium material solution.

Material Showdown: Standard vs. Premium Screws

For premium eyewear, screws must be made from high-grade materials. High-strength machined screws are created on a lathe for precise, clean threads, while low-quality molded screws have imprecise threads prone to stripping.

Best Practice: The baseline for durability is high-grade stainless steel, which provides the necessary tensile strength and corrosion resistance. The critical innovation is a nylon-coated, thread-locking patch (like Nylok) bonded to the threads. This nylon compresses when tightened, creating strong friction that resists loosening and effectively locks the screw in place.

6. The Temple (or Arm): Ensuring a Secure and Comfortable Fit

The Common Problem: Temples That Break Easily or are Impossible to Adjust

Temples on low-quality frames either snap under pressure or cannot be adjusted for a custom fit. This is due to the use of brittle materials or, in plastic frames, the absence of a metal core wire for reinforcement. An acetate temple without a core is weak, and a metal temple made from a brittle alloy will fracture when an optician tries to adjust it.

Function: Extending from the Hinge to Rest Over the Ears

Definition: The temples are the long arms that extend from the frame front to sit over the ears, securing the glasses on the wearer’s face. The temple’s length, curvature, and material are key to long-term comfort and preventing slippage.

Pro Tip: While bridge fit is important, the final security of the frame is achieved by an optician carefully bending the temple tips to contour perfectly behind the wearer’s ears. This adjustability is a key feature of all premium eyewear.

Premium Material Options for Temples

- Acetate (with a core wire): This combination allows for the rich color possibilities of acetate while providing the strength and adjustability of a metal skeleton.

- Titanium: Ideal for minimalist designs, titanium temples can be made incredibly thin and light while retaining exceptional strength for all-day comfort.

- Stainless Steel: Another excellent option for thin, durable metal temples, offering performance similar to titanium at a more accessible cost.

- Carbon Fiber: These temples are extremely lightweight and rigid, offering a high-tech aesthetic, but they cannot be adjusted for fit.

7. The Core Wire: The Hidden Skeleton of Acetate Frames

The Common Problem: Acetate Temples That Snap or Cannot Be Adjusted

When a customer complains that their plastic frames feel weak or their optician was unable to adjust them, it is a tell-tale sign of a frame made without a core wire. Its absence is a deliberate cost-cutting measure that severely compromises the frame’s quality and functionality.

Most Importantly: All high-quality, hand-crafted acetate frames will have a metal core wire. Cheap, mass-produced injection-molded frames almost never do. The presence of a core wire is an immediate and reliable indicator of superior construction.

Function: Providing Strength and Adjustability to Acetate Temples

Definition: The core wire is a metal rod inserted into an acetate temple to provide structural reinforcement and allow for precise fitting adjustments. The wire is inserted through a process called “temple shooting,” where the heated acetate is injected around the wire.

Simple Analogy: The core wire is like rebar in concrete, providing hidden tensile strength. Just as rebar reinforces concrete, the core wire provides the strength that the surrounding acetate lacks, preventing it from breaking or losing its shape.

Material & Design Insights

The material choice for the core wire matters. Here is a breakdown of your options:

- Good: Nickel Silver is a common, cost-effective option but can cause allergic reactions if the acetate wears down and it becomes exposed.

- Better: Stainless Steel offers superior strength and corrosion resistance, preventing issues if moisture gets inside the temple.

- Best: Titanium provides the ultimate combination of strength, lightness, and is 100% hypoallergenic, making it the premium choice.

Best Practice: In high-end eyewear, engraved core wires visible through translucent acetate serve as a subtle signature of craftsmanship and a premium design element. A key quality marker is ensuring the wire is perfectly centered within the temple.

8. The Temple Tip: The Point of Contact for Comfort

The Common Problem: Irritation or Slippage Behind the Ear

Discomfort behind the ear is often caused by a temple tip made from a hard, slippery material or one that causes an allergic reaction. The material choice for this direct contact point must prioritize both long-term skin comfort and sufficient grip to prevent the frame from sliding.

Function: Cushioning the End of the Temple Behind the Ear

Definition: The temple tip is the covering on the end of the temple arm that rests behind the ear, providing comfort and a secure fit. The transition from the temple to the temple tip should be seamless, with no sharp edges or rough textures.

Premium Material Options

- Acetate: On acetate frames, the tip is an integrated, polished part of the temple. On metal frames, a separate acetate tip can be added for a smooth, hard, and hypoallergenic contact point.

- Soft-touch Silicone: Silicone tips provide a soft, rubbery texture that increases grip, making them ideal for performance and sports frames where preventing slippage during activity is critical.

- Rubberized coatings: A thin rubberized coating can be applied to metal temple tips to provide a soft-touch feel and enhance grip, combining a slim profile with the comfort of a softer material.

9. The Pad Arm: The Key to a Customized Fit

The Common Problem: The Frame Sits Too High, Too Low, or Crooked

A common complaint with metal frames is a poor fit that could easily be solved by adjustable pad arms. This issue is frequent in low-cost metal frames that have fixed, non-adjustable nose pads, removing the most important element of fit customization.

Function: Connecting the Nose Pad to the Frame Rim

Definition: Pad arms are the small metal arms that extend from the rims to hold the nose pads in place. Their primary function is to be adjustable, allowing an optician to customize the fit. By carefully bending the pad arms, an optician can fine-tune the position of the nose pads, ensuring the frame sits at the correct height and distance from the face.

Material Showdown: Stainless Steel vs. Titanium

Both stainless steel and titanium are excellent materials for pad arms. Titanium offers slightly better flexibility and memory, making it more resistant to breaking after repeated adjustments. It is also 100% hypoallergenic, making it the superior choice for preventing any potential skin irritation on the nose.

Critical Warning: The joint connecting the pad arm to the rim is a high-stress point. Standard soldering can create a weak joint. Superior manufacturing uses high-temperature brazing or, for titanium, laser welding in an argon gas environment to create a much stronger, more reliable bond.

10. The Nose Pad: Supporting the Frame in Comfort

The Common Problem: Frames That Slide Down the Nose or Cause Allergic Reactions

Slippage and skin irritation are often caused by using hard, low-grip PVC nose pads or materials that are not hypoallergenic. The nose pad material must provide enough grip to support the weight of the frame and must be biocompatible to avoid causing skin reactions.

Function: Resting on the Nose to Provide Grip and Support

Definition: Nose pads are the small, cushioned components that rest on the sides of the nose to distribute the frame’s weight and prevent it from slipping.

Pro Tip: For heavier frame and lens combinations, high-grip silicone nose pads are essential to keep the eyewear securely in place. The choice of nose pad material is a small detail that has a massive impact on the wearer’s daily comfort.

Material Showdown: Silicone vs. Titanium vs. PVC

| Feature | Silicone | PVC (Polyvinyl Chloride) | Titanium |

| Grip & Slip-Resistance | Excellent | Poor | Moderate |

| Comfort & Softness | Very High (Soft & Pliable) | Low (Hard & Rigid) | Moderate (Hard but Smooth) |

| Durability & Discoloration | Good (Porous, can yellow over time) | Excellent (Non-porous, no discoloration) | Ultimate (Non-porous, no corrosion) |

| Hypoallergenic Properties | Generally good | Can cause reactions | 100% Hypoallergenic |

| Best For | All-purpose comfort and grip | Durability in clean environments | Ultimate durability & sensitive skin |

11. The Lens: The Heart of the Eyewear

The Common Problem: Lenses That are Heavy, Distort Vision, or Shatter Easily

A premium frame can be completely ruined by a poor lens choice. Heavy, low-clarity lenses create an uncomfortable and optically inferior product, regardless of frame quality. The lens material must be selected based on the user’s prescription strength, lifestyle, and the frame type.

Function: The Optical Element Providing Vision Correction or Protection

Definition: Lenses are the transparent components, made from glass or optical-grade polymers, that are ground to a specific prescription to correct vision or are treated to provide protection from UV light.

Pro Tip: The frame’s design must support the weight and thickness of the required lens. For high-prescription wearers, a smaller, thicker frame is often a better choice as it can better support and conceal the edge thickness of a strong lens.

Premium Lens Material Options

- CR-39: An optical plastic with the highest clarity of any plastic lens material (Abbe value of 58), minimizing color fringing. It has excellent scratch resistance but requires a separate UV coating.

- Polycarbonate: Extremely impact-resistant, making it the standard for safety and children’s eyewear. However, it has poor optical clarity (Abbe value of ~30).

- Trivex: Offers the best of both worlds: the impact resistance of polycarbonate combined with excellent optical clarity (Abbe value of ~45). It is also the lightest of all lens materials.

- Nylon: A top choice for high-end sunglasses, nylon lenses are extremely lightweight, flexible, and impact-resistant, with excellent optical clarity (Abbe value ~45-50).

- High-Index Plastics: For strong prescriptions, these materials (e.g., 1.67, 1.74) bend light more efficiently, allowing the lens to be made significantly thinner and lighter. An anti-reflective coating is mandatory.

12. Rimlocks & 13. Top Bar: Specialized Structural Components

Rimlocks: The Lens-Securing Mechanism

Definition: The rimlock is the tiny screw-based mechanism on a metal frame that allows the eyewire to be opened for lens insertion and then securely tightened to hold the lens in place. The rimlock screw must be made of high-tensile stainless steel to withstand the required torque without stripping the threads or head.

Top Bar: The Reinforcing Brow Bar

Definition: A top bar (or brow bar) is a second bar that connects the rims above the bridge. It adds structural stability and is a key design feature of aviator and other vintage-inspired styles. The top bar is almost always made from the same material as the rest of the frame front (e.g., Titanium, Steel) to ensure aesthetic and structural consistency.

Why Frames Fail: A Manufacturer’s Guide to Common Component Issues

Understanding Acetate Discoloration (“Blooming”)

Definition: “Blooming” is a white, hazy film that forms on acetate frames. It is caused by plasticizers within low-grade material migrating to the surface and oxidizing upon exposure to UV light and skin oils.

Best Practice: This is prevented by sourcing high-quality, properly cured cellulose acetate from top suppliers like Mazzucchelli. Ensuring the material undergoes a multi-week curing process stabilizes the plasticizers and guarantees product longevity.

Diagnosing Hinge & Screw Corrosion

Definition: Galvanic corrosion occurs when dissimilar metals (like a nickel-alloy hinge and a steel screw) are in contact in the presence of an electrolyte like sweat. This electrochemical reaction degrades the less noble metal, leading to the green residue and structural failure common in cheap hardware.

Simple Analogy: Think of galvanic corrosion like a tiny, destructive battery. The two different metals and the salty sweat create a circuit that eats away at one of the metals, causing it to fail. This is why using a single, corrosion-resistant material like stainless steel or titanium for all hardware is the best prevention.

The Anatomy of a Weld Break

Critical Warning: When welding metals like titanium, any exposure to oxygen during the process will contaminate the weld, creating an extremely brittle joint that is destined to fail. This is a common manufacturing defect in facilities with poor quality control.

Best Practice: Welding titanium must be done in an oxygen-free environment, typically a chamber flooded with inert argon gas. This prevents contamination and creates a strong, ductile weld that is actually stronger than the surrounding material, ensuring the joint will never be the point of failure.

Beyond the Basics: How Premium Components are Tested for Quality

Hinge Cycle Testing for Long-Term Durability

The Kssmi Protocol: We mandate automated testing for 20,000+ open-and-close cycles. While the ISO 12870 standard only requires 500 cycles, this rigorous testing simulates years of real-world use to ensure no structural failure and minimal loss of tension over the product’s lifespan.

The Salt Spray Test for Corrosion Resistance

The Kssmi Protocol: We mandate standardized salt spray tests (ISO 9227) for 24-72 hours. This accelerated corrosion test simulates a lifetime of exposure to sweat and guarantees that our coatings will not peel and our base materials will not corrode or tarnish.

Verifying Purity with Hypoallergenic XRF Analysis

The Kssmi Protocol: We require X-ray fluorescence (XRF) analysis reports from our suppliers. This non-destructive test provides scientific proof of the elemental composition of our metal components, verifying that nickel content is below the 0.5% threshold that could cause contact dermatitis.

The Kssmi Component Material Matrix: A Strategic Decision Framework

How to Use This Framework to Build a Superior Product

The following matrix is more than just a table of data; it’s a strategic decision-making tool. Most brands only consider material choices for the frame front, but true quality comes from making deliberate, informed decisions for every single component. This framework allows you to do just that.

Simple Analogy: Think of this matrix as a nutritional label for your product’s components. It allows you to see the trade-offs between different material “ingredients” for each part. You can balance cost against performance, align material choices with your brand’s market position, and write a tech pack with unparalleled precision. This system transforms a simple list of parts into a powerful, data-driven method for engineering a superior product.

The Master Reference Table

| Component | Material Option | Durability & Longevity (1-5) | Mfg. Complexity & Cost (1-5) | Weight & Comfort (1-5) | Aesthetic & Design Versatility (1-5) |

| Rim/Frame Front | Good: Stainless Steel | 4 – Very strong, corrosion-resistant. | 3 – More affordable than titanium. | 3 – Lightweight, but denser than Ti. | 3 – Good for thin, minimalist designs. |

| Better: Mazzucchelli Acetate | 4 – Durable and holds shape well. | 4 – Labor-intensive CNC milling. | 4 – Lightweight and warm feel. | 5 – Unparalleled color and depth. | |

| Best: Beta Titanium | 5 – Ultimate strength and flexibility. | 5 – Very complex to weld, high cost. | 5 – Highest strength-to-weight ratio. | 4 – Excellent for ultra-thin designs. | |

| Hinge | Good: 5-Barrel Nickel Silver | 3 – Good strength but prone to corrosion. | 2 – Industry standard, inexpensive. | 3 – Standard weight. | 2 – Standard functional appearance. |

| Better: 5-Barrel Stainless Steel | 4 – Excellent strength & corrosion resistance. | 3 – More costly but very durable. | 3 – Standard weight. | 3 – Clean, industrial look. | |

| Best: 7-Barrel Titanium | 5 – Max strength, zero corrosion. | 5 – Most expensive, precise mfg. | 5 – Lightest and strongest option. | 4 – A mark of high-end engineering. | |

| Screw | Good: Standard Stainless Steel | 3 – Strong but will loosen over time. | 2 – Inexpensive and mass-produced. | 5 – Negligible weight. | 1 – Purely functional. |

| Better: Machined Stainless Steel | 4 – Precise threads for a more secure fit. | 3 – Machining adds cost but improves quality. | 5 – Negligible weight. | 1 – Purely functional. | |

| Best: Nylon-Coated Machined Steel | 5 – Nylon patch prevents loosening entirely. | 4 – Coating is an additional mfg. step. | 5 – Negligible weight. | 2 – Blue patch is a quality indicator. | |

| Core Wire | Good: Nickel Silver | 3 – Provides rigidity but can be an allergen. | 2 – Inexpensive and easy to work with. | 3 – Adds necessary weight for balance. | 2 – Functional, can be engraved. |

| Better: Stainless Steel | 4 – Stronger and corrosion-resistant. | 3 – More difficult to “shoot” into acetate. | 3 – Adds necessary weight for balance. | 3 – Can be polished to a high shine. | |

| Best: Titanium | 5 – Highest strength, lowest weight. | 4 – Most difficult to work with. | 5 – Reduces overall temple weight. | 4 – Ideal for premium engraved designs. | |

| Nose Pad | Good: PVC | 3 – Very durable and does not discolor. | 1 – Very inexpensive. | 1 – Hard and can be uncomfortable. | 2 – Standard clear or frosted look. |

| Better: Silicone | 4 – Excellent grip and very comfortable. | 2 – Inexpensive but can yellow over time. | 5 – Softest and most comfortable option. | 3 – Available in various shapes/sizes. | |

| Best: Titanium | 5 – Extremely durable, 100% hypoallergenic. | 4 – Most expensive pad material. | 3 – Hard surface but lightweight/smooth. | 5 – Premium metallic look. |

Conclusion

A premium frame is the result of a holistic approach where every part, from the rim material down to the screw coating, is specified for performance. By using the Kssmi Component Material Matrix, you can move beyond simple frame-front choices and begin making the component-level decisions that prevent product failures, build brand trust, and create a truly superior product. Let’s work together to build your next collection with this level of detail.

Frequently Asked Questions

1. What is the single most important component to upgrade for perceived quality?

The hinge. The tactile feel of opening and closing the temples provides immediate feedback. A smooth, sturdy, multi-barrel hinge feels significantly more premium than a flimsy one.

2. Why do some acetate frames feel cheap while others feel luxurious?

The difference is the material source and manufacturing process. Luxurious acetate (e.g., Mazzucchelli) is plant-based, cured for weeks, and CNC-milled from a block. Cheap frames use injection-molded plastic that is brittle and lacks a metal core wire for reinforcement.

3. Are titanium frames really worth the extra cost?

Yes, for users who prioritize comfort, durability, and skin safety. Titanium is significantly lighter and stronger than steel and is 100% hypoallergenic, making it worth the investment for those with nickel allergies.

4. How can I tell if a hinge is high-quality just by looking at it?

Count the barrels. A high-quality standard hinge will have five or seven interlocking barrels, which provides more stability than a basic three-barrel hinge. Also, look for the absence of any green or white corrosion.

5. What is the most common point of failure on a pair of glasses?

The hinge screw. The constant vibration from daily use causes standard screws to loosen and fall out. This is why premium frames use nylon-coated, self-locking screws to prevent this common failure.