Custom Eyewear Brand from Vision to Victory Ultimate Guide

You can achieve scalable market entry through private label, OEM, or custom manufacturing partnerships. A successful launch hinges on integrating your market position with precise technical specs and a verified partner who meets global standards like CE, FDA, and ISO. Your competitive edge will come from smart material choices, robust quality control, and an efficient supply chain.

Phase 1: Architecting Your Brand Foundation and Market Strategy

From Market Analysis to Competitive Advantage

Your market positioning strategy determines every decision you’ll make, from materials to partners. The eyewear industry’s massive market value shows the opportunity is there, but your success requires you to find a precise niche and differentiate your brand clearly from the competition. Strategic analysis is your starting point for every decision that follows.

Deconstructing the Competitive Landscape

The eyewear market is generally broken down into three main tiers. Understanding where you fit helps you define your product, story, and price point.

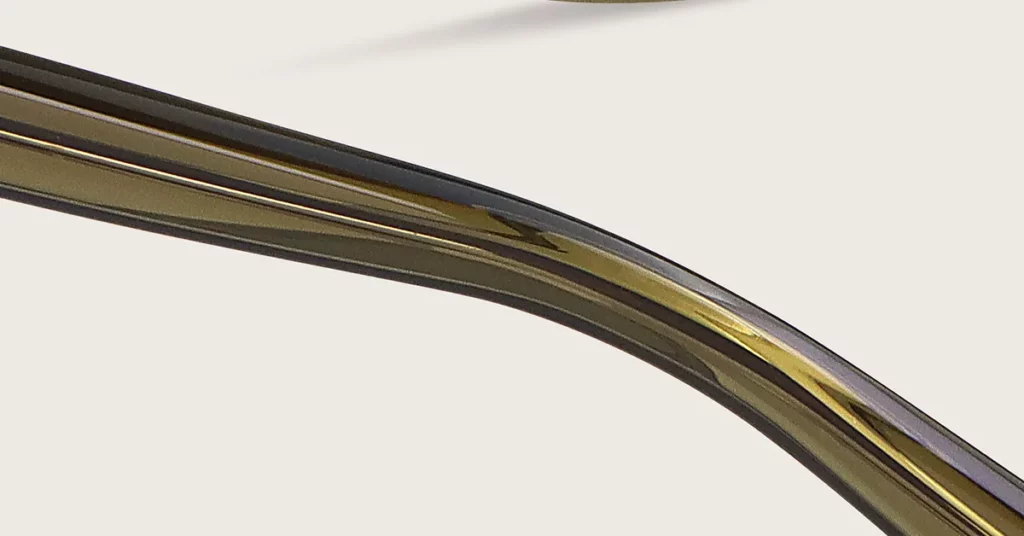

- Luxury: This tier commands premium prices through heritage, superior materials like Italian Mazzucchelli acetate, and artisanal craftsmanship. Brands like Tom Ford and Prada use their fashion house recognition to justify frames well over $400.

- Performance: Here, the focus is on technical innovation. Brands like Oakley lead with advanced lens technologies and lightweight materials for specific sports. Functionality is the key driver, creating space for highly specialized products.

- Direct-to-Consumer (DTC): This tier, led by brands like Warby Parker, changed the game by cutting out the middleman. Technology-driven experiences like virtual try-on lower customer acquisition costs while helping maintain a premium feel.

Identifying High-Value B2B and Consumer Niches

You can find powerful opportunities by targeting specific, underserved segments.

- Eco-Luxury: This fast-growing niche brings sustainability to the premium market. Bio-acetate and recycled materials attract environmentally conscious buyers who will pay more for responsible manufacturing.

- Specialized Sports: Think beyond mainstream athletics. Professionals in aviation, marine operations, or precision shooting need specific optical performance, justifying higher margins and building strong customer loyalty.

- Bespoke Fashion: This segment serves affluent clients who want unique, personalized designs. You can command premium prices here through deep customization and limited-edition releases that create a sense of scarcity.

Translating Macro-Level Trends into a Bankable Product Concept

Staying ahead of broad market shifts gives your product an immediate advantage.

- Digital Eye Strain: With remote work and screen time as the new normal, demand for blue light filtering lenses is soaring. This creates a powerful marketing angle centered on health and wellness benefits.

- Demographic Shifts: Aging populations in developed countries are driving demand for prescription eyewear, while emerging markets show strong growth in fashion-focused frames. Your geographic focus will shape your strategy.

- Smart Eyewear: The integration of augmented reality and other smart features is the future. Getting into this category early requires technical partnerships but offers a significant first-mover advantage.

Impact of “Made In” Designations on Positioning and Cost

Where your eyewear is made sends a strong message about your brand and directly impacts your cost structure.

| Manufacturing Origin | Positioning Impact | Cost Structure |

| Italy | Carries a strong premium and luxury association. | Significantly higher production costs. |

| China | Offers cost advantages with high quality from certified suppliers. | Substantial cost savings. |

Key Metric: You can typically expect 40-60% cost savings from established Chinese manufacturers compared to European production, while still maintaining exceptional quality through ISO certifications and robust quality control systems.

Defining Your Brand Identity and Unique Value Proposition (UVP)

Your brand identity is more than a logo; it’s the core value you promise your customers. Your UVP needs to resonate with your target audience and justify your price point while being something you can deliver on consistently. Successful brands build this identity on clear, unwavering pillars.

Establishing Your Core Pillars

- Unmatched Craftsmanship: This pillar emphasizes handmade production, premium materials, and artisanal finishing. It supports luxury pricing but demands a manufacturing partner with proven expertise in traditional techniques.

- Technological Innovation: This focus is on advanced materials, proprietary lens tech, or smart features. It requires R&D investment or strategic partnerships but carves out a defensible niche in crowded markets.

- Sustainability Leadership: This pillar addresses environmental consciousness through eco-friendly materials and responsible production. It appeals deeply to a growing segment of consumers and builds a powerful brand story.

Crafting a Compelling Brand Story

Your brand story is what turns a product feature into an emotional connection. An effective story speaks to your customer’s needs and positions your brand as the ideal solution. You can build this narrative around heritage and tradition, problem-solving innovation, or an authentic personal story from the founder.

Engineering Your Pricing Strategy

Your pricing must balance your market position, production costs, and profit goals. Premium pricing requires strong differentiation, while value pricing focuses on operational efficiency to stay competitive.

Pro Tips: In my two decades in this business, I’ve seen that successful eyewear brands consistently target 65-70% gross margins. This buffer is what allows you to invest in marketing, manage inventory effectively, and fund sustainable growth without compromising your position.

Building Defensibility Through Customization

Customization is a powerful way to create loyalty and justify premium prices.

- Bespoke Services: Offering complete customization from the frame shape to the lens specs. This is the highest tier of service and commands the highest prices.

- Personalized Options: Providing services like custom engraving, color choices, or fit adjustments. These options increase the average order value without overhauling your production line.

- Limited-Edition Releases: Using scarcity to create buzz and drive sales. Timed releases for seasons, collaborations, or special events are highly effective.

Solidifying Your Business Framework for Long-Term Success

A solid business framework is the foundation for scalable growth. It sets up your operations, protects your intellectual property, and manages your financial resources. Planning this from the start prevents expensive problems down the road and allows you to scale efficiently.

Selecting the Right Business Model

- DTC (Direct-to-Consumer): Offers higher margins and a direct line to your customer but requires heavy investment in marketing and operations.

- B2B Wholesale: Provides rapid market access through existing retail networks but requires different pricing strategies and partner support.

- Hybrid: Combines both DTC and wholesale to maximize reach and optimize margins, but requires careful channel management to avoid brand dilution or price conflicts.

Developing a Robust Financial Plan

You need to map out your startup costs, revenue projections, and funding strategy. A comprehensive launch, including sufficient inventory, typically requires an initial investment of $250,000 to $500,000. Your financial plan should include conservative projections for planning and more aggressive scenarios to evaluate your full potential.

Navigating Legal Essentials

Properly handling legal requirements is non-negotiable. This includes business registration, tax IDs, and any industry-specific licenses. For international brands, you must understand import/export licenses, customs, and duties. You also need to comply with industry regulations like FDA requirements in the US and CE marking in Europe to ensure market access.

Protecting Your Brand

- Trademarks: These protect your brand name and logo.

- Design Patents: These protect the unique aesthetic design of your frames.

Critical Warning: The eyewear market is saturated, leading to high rejection rates for new trademark applications. You must invest in a professional trademark search and filing strategy to avoid costly legal conflicts and ensure your brand is properly protected.

Phase 2: Translating Vision into a Market-Ready Product Blueprint

Mastering Frame Design and Material Science

Your choice of frame material affects everything—performance, cost, aesthetics, and brand position. Understanding material science is essential for making informed decisions and for establishing clear quality standards with your manufacturing partner.

Strategic Selection of Core Materials

Each material offers a different balance of properties, costs, and manufacturing needs.

| Material | Key Characteristics | Best For | Manufacturing Notes |

| Acetate | Unlimited color/pattern flexibility, comfortable, adjustable. | Fashion & Luxury | High-grade options like Mazzucchelli increase cost by 30-40%. |

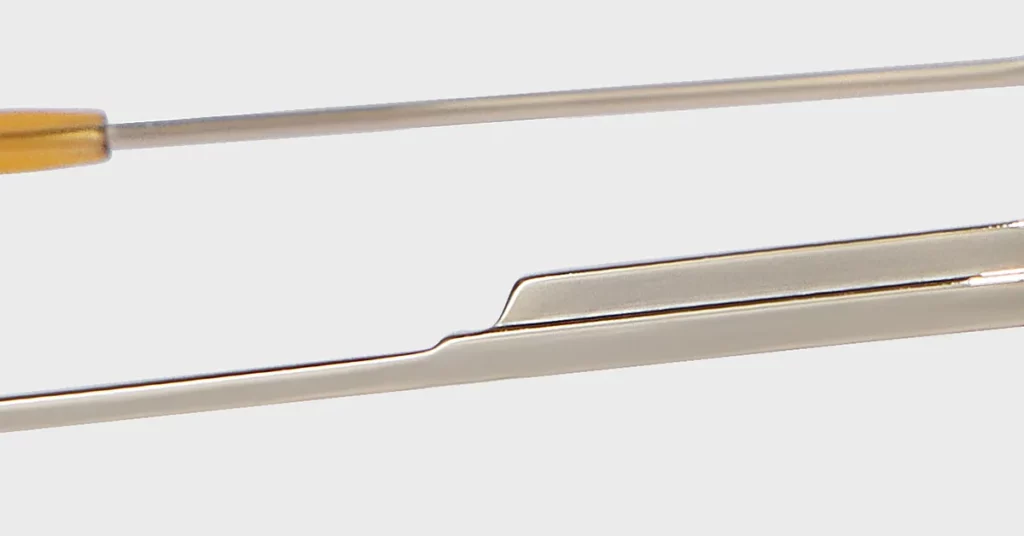

| Titanium | Exceptional strength-to-weight ratio, hypoallergenic. | Premium & Performance | Manufacturing requires specialized equipment and expertise. |

| Stainless Steel | Durable, modern aesthetic, good corrosion resistance. | Active Lifestyle & Value | Versatile for many finishing techniques. |

| Wood & Horn | Unique, natural aesthetic. | Eco-Luxury & Bespoke | Requires specialized processing; higher material waste rates. |

Innovating with Advanced Materials

New materials are constantly opening up new design possibilities.

- 3D-Printed Polymers: Offer limitless customization with minimal waste. The surface finish quality is improving rapidly, making this a viable option for small-batch production.

- Carbon Fiber: Provides exceptional strength and is incredibly lightweight, ideal for high-performance sports and premium lifestyle frames. Its complexity keeps it in specialized segments.

- Bio-Resins: Address the growing demand for sustainable products. These materials command a premium but appeal directly to eco-conscious consumers.

Balancing Material Properties

Your material choice creates a trade-off between weight, durability, and production complexity. Lighter frames are more comfortable for all-day wear but may cost more to produce. Durability needs vary; performance frames need impact resistance, while fashion frames prioritize a lasting finish.

Key Metric: Frame weight targets differ by category. Luxury acetate frames typically weigh 20-30 grams, titanium frames are lighter at 15-25 grams, and high-performance frames can be as light as 10-20 grams for optimal comfort.

Implementing Material Traceability for Sustainable Brands

If sustainability is one of your core pillars, supply chain transparency is essential. Documented material origins, certified sustainable sourcing, and carbon footprint tracking are what turn a marketing claim into an authentic brand value. This adds operational complexity but is a powerful differentiator.

Creating a Manufacturer-Ready Tech Pack

Your tech pack is the blueprint you give your manufacturer. It translates your design vision into a set of precise instructions. A comprehensive tech pack prevents costly misunderstandings and ensures you get consistent quality. It should include technical drawings, a complete bill of materials (BOM), and exact measurement specifications with tolerances.

Engineering the Perfect Lens

Lens technology is a major factor in your product’s performance and a key part of its story. Strategic lens selection supports your brand’s positioning, meets regulatory standards, and can justify a higher price point.

Comparative Analysis of Lens Materials

| Material | Key Characteristics | Best For |

| Polycarbonate | High impact resistance, lightweight, great clarity. | Active Lifestyles & Safety |

| Trivex | Superior optical clarity, matches polycarbonate in impact resistance. | Premium & Luxury |

| High-Index Plastics | Enables thinner, lighter lenses for strong prescriptions. | Prescription Eyewear |

| Mineral Glass | Unmatched optical clarity and scratch resistance. | Ultra-Luxury |

Exceeding Global Standards for UV Protection

Comprehensive eye safety requires blocking harmful UV radiation up to 400nm. This includes both UVA rays, which cause long-term damage, and UVB rays, which cause acute issues like inflammation.

Best Practice: You should specify UV400 protection as a standard feature across your entire lens collection. This ensures you meet international regulations and gives you a strong, health-focused marketing message.

Selecting High-Value Lens Coatings

- Anti-Reflective (AR): Improves visual clarity and reduces eye fatigue from glare.

- Anti-Scratch: A hard coating that extends the life of the lens.

- Hydrophobic: Repels water, oil, and dirt, keeping vision clear in challenging conditions.

- Blue Light Filtering: Addresses digital eye strain, a major concern for today’s consumers.

Incorporating Advanced Lens Technologies

- Polarization: Eliminates glare from reflective surfaces, enhancing contrast and comfort, especially for driving and outdoor activities.

- Photochromic: Lenses that automatically adjust their tint based on lighting conditions.

- Prescription (Rx) Integration: Offering to fit your frames with prescription lenses creates a complete optical solution and builds customer loyalty.

Perfecting Product-Market Fit Through Prototyping

Iteration is key to getting your product right before committing to a full production run. Strategic prototyping reduces development costs and helps you validate the fit, comfort, and aesthetic appeal of your design, maximizing its market acceptance.

Leveraging Virtual Try-On (VTO) and Fit Analytics

Modern VTO technology allows customers to see how frames look on their face, providing you with valuable fit validation data without needing a physical prototype. This data can be used to optimize your designs for a wider range of face shapes, improving conversion rates and reducing returns.

The Physical Prototyping Process

- 3D Printing: Enables rapid and low-cost iteration, perfect for validating a design’s shape and fit.

- CNC Milling: Creates production-accurate prototypes that confirm your manufacturing processes and quality expectations.

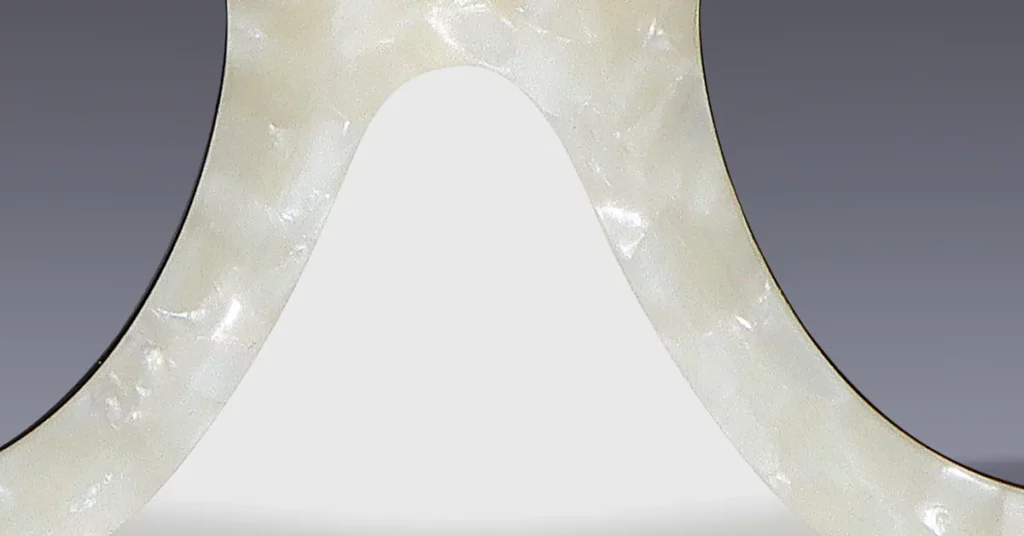

- Handmade Sampling: Essential for materials like acetate that require traditional craftsmanship. This approach validates the final look and feel of your product.

Establishing an Iterative Feedback Loop

You must collect feedback throughout the prototyping process. Use focus groups, wear trials, and expert reviews to guide your design refinements. This systematic approach ensures you catch potential ergonomic or aesthetic issues early and confirms that your design resonates with your target market.

Ensuring Compliance with Critical Industry Standards

- ANSI Z87.1: The standard for safety eyewear in the US, covering impact resistance and optical quality.

- ISO 12312-1: The international standard for sunglasses, covering UV protection and durability.

Critical Warning: Compliance with these standards requires verified testing documentation from an accredited lab. Do not rely on a manufacturer’s self-certification. Unverified claims create serious liability risks and can get your product pulled from the market.

Phase 3: Mastering the Manufacturing and Supply Chain Ecosystem

Choosing the Right Partnership Model for Your Business

Your manufacturing partner determines your product quality, cost, and ability to scale. You need to choose a partnership model that aligns with your business goals, quality requirements, and long-term vision.

| Partnership Model | Description | Best For |

| Private Label | Customizing a manufacturer’s existing designs with your branding. | Speed to market with minimal investment. |

| OEM (Original Equipment Manufacturer) | Your unique design is produced by a partner using their components/supply chain. | Brands with a strong design vision but limited technical expertise. |

| ODM (Original Design Manufacturer) | Co-creating a new product, blending your brand vision with a manufacturer’s core IP. | Balancing innovation with manufacturing feasibility. |

| Bespoke Workshop | Artisanal, handmade production for completely custom frames. | Ultra-luxury, small-batch, or limited-edition collections. |

Pro Tips: An OEM partnership gives you great design control while benefiting from a manufacturer’s efficiency. However, an ODM partnership can accelerate your development timeline by leveraging your partner’s existing technologies and design expertise. The choice depends on how much control you need versus how fast you want to move.

A Framework for Vetting Your Manufacturing Partner

A systematic evaluation of potential partners is one of the most important steps you will take. This process prevents costly mistakes and ensures you find a partner who can grow with you.

Assessing Core Capabilities

Look at a potential partner’s production capacity, technical specializations, and the quality of their equipment. In my two decades crafting handmade eyewear, I’ve consistently observed that a factory’s investment in modern, well-maintained equipment is a direct indicator of their commitment to quality. Ask for production examples and client references to verify their track record.

Evaluating Production Scalability

You need to understand a partner’s minimum order quantities (MOQs) and their ability to handle larger volumes as you grow. A partner who is flexible and can scale with you prevents production bottlenecks during your expansion phases.

Key Metric: Standard MOQs vary significantly by material. You can expect MOQs of 300-600 pieces for acetate frames, 600-1,200 for metal frames, and potentially over 1,200 for more specialized materials due to higher setup costs.

Auditing Quality Control Systems

Verify that your partner has robust quality management systems in place. Look for ISO 9001 certification, which indicates a structured approach to quality. Ask to see their documented procedures for in-line inspections, final testing, and how they track and correct defects.

Conducting Financial and Operational Due Diligence

You must assess a partner’s financial stability to ensure they are a reliable, long-term choice. Also, evaluate their management team, workforce stability, and communication systems. Strong communication is the bedrock of a successful partnership, especially when navigating different time zones and languages.

Managing the Production and Quality Assurance Process

Active management of your production runs is essential for maintaining quality, hitting deadlines, and controlling costs. A systematic quality assurance (QA) process establishes your standards and catches issues before they become major problems.

From Sample Approval to Production Run

Your final, approved sample is the quality benchmark for the entire production run. Once you approve it, work with your partner to create a clear production schedule that coordinates material procurement, manufacturing, and delivery. Regular progress updates and inspection checkpoints are key to staying on track.

Defining Your Quality Control Manifesto

This is your internal document that details every quality standard. It should include:

- Acceptable tolerances for all critical dimensions.

- Protocols for testing optical performance and durability.

- Specific inspection points at critical stages of production.

- Requirements for all documentation, including test results and inspection records.

The Critical Importance of Legal Protections

Your relationship with your manufacturer must be protected by clear legal agreements. A Non-Disclosure Agreement (NDA) protects your proprietary designs, while a comprehensive Manufacturing Agreement establishes all responsibilities, quality standards, delivery schedules, and dispute resolution procedures. This protects your IP and holds your partner accountable.

Building a Resilient Supply Chain

A resilient supply chain ensures you have consistent access to materials and components, protecting you from disruptions. Diversifying your suppliers for key components reduces your risk and gives you more flexibility.

Sourcing High-Quality Components

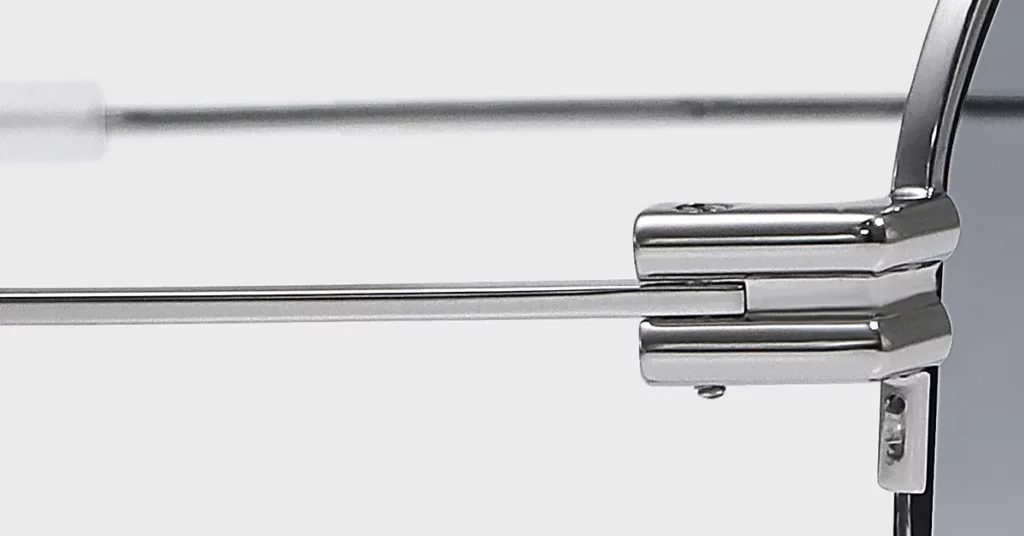

The small parts—hinges, screws, and nose pads—have a huge impact on the final product’s durability and the user’s experience. Using premium components from respected suppliers like OBE is a small investment that pays off in customer satisfaction and a stronger brand reputation.

Designing and Sourcing Brand-Aligned Packaging

Your packaging is the first physical interaction a customer has with your brand. It must protect the product while communicating your brand’s values. If sustainability is a core value, use eco-friendly materials. Your packaging design should balance protection, aesthetics, and cost to be effective.

Navigating Global Logistics

Successfully managing international shipping requires expertise in customs, tariffs, and documentation.

Pro Tips: You should establish relationships with an experienced customs broker and freight forwarder early in your process. Their expertise is invaluable and will help you prevent costly delays and navigate the complexities of international logistics as you grow.

Phase 4: Executing a High-Impact Go-to-Market Strategy

Architecting Your Sales and Distribution Channels

Your channel strategy determines your market reach and profitability. Whether you choose DTC, wholesale, or a hybrid model, your approach must align with your brand positioning and customer acquisition goals. A multi-channel strategy can maximize your coverage, but it requires careful management to ensure a consistent brand experience.

Building a High-Conversion E-commerce Platform

Your online store needs to be optimized for selling eyewear. This means integrating high-quality VTO capabilities, a seamless prescription lens ordering process, and detailed product visuals. Since many customers will shop on their phones, a mobile-first design is essential for engaging them effectively.

Forging Strategic Wholesale and Retail Partnerships

Wholesale partnerships can give you instant access to established retail networks and their customer bases. When selecting retail partners, make sure their target customer and brand image align with yours. Providing your partners with training, marketing materials, and great support will ensure your brand is represented well and will maximize their sales performance.

Creating Brand Experiences

Pop-up shops and live events are powerful ways to build buzz and let customers interact with your product directly. Experiential marketing is particularly effective for eyewear, where fit and feel are major purchase drivers. Partnering with fashion events or complementary lifestyle brands can amplify your reach and impact.

Integrating Prescription Lens Fulfillment

If you offer prescription lenses, you need a seamless fulfillment process. This involves partnering with a certified optical lab and creating a simple, streamlined online ordering and verification system. Quality control is paramount here to ensure accuracy and customer satisfaction.

Developing Your Launch Marketing and Content Engine

A strong marketing strategy is what builds awareness and drives your initial sales. Your content should establish your brand’s authority, educate your customers, and support your premium positioning.

Designing a Multi-Channel Launch Campaign

Your launch campaign should deliver a coordinated message across all your channels—social media, email, PR, and paid ads. Customizing your message for each platform while maintaining a consistent brand voice will improve engagement and drive conversions. Use analytics to track your performance and optimize your campaign in real time.

Creating Compelling Product Photography and Videography

For a visual product like eyewear, the quality of your imagery directly impacts sales. You need professional photography that showcases the style, fit, and quality details of your frames. Use video to tell your brand story, demonstrate features, and create engaging styling guides.

Executing a Digital Marketing Blueprint

- Social Media: Use visual platforms like Instagram to build a community and showcase your products in an authentic way.

- Email Marketing: Nurture customer relationships and drive repeat purchases with automated email flows for new subscribers, abandoned carts, and post-purchase follow-ups.

- SEO: Invest in search engine optimization to drive long-term organic traffic, which will lower your customer acquisition costs over time.

- Influencer Collaborations: Partner with influencers whose audience and values align with your brand to gain authentic endorsements and targeted reach.

Driving Authority Through Public Relations

PR builds credibility through earned media coverage in fashion publications, lifestyle magazines, and trade media. Positioning your founder or brand as an expert in the field through thought leadership articles or commentary enhances your authority and supports a premium brand image.

Phase 5: Driving Sustainable Growth and Scaling Operations

Delivering a World-Class Customer Experience

A superior customer experience is a sustainable competitive advantage. It drives retention, referrals, and long-term value. This means managing every touchpoint, from their first visit to your website to your post-purchase support.

Defining Your Warranty, Repair, and Return Policies

Clear and fair policies build customer trust. A strong warranty demonstrates your confidence in your product’s quality. Offering repair services can extend the life of a product and increase customer satisfaction. Your return policy should be simple and customer-friendly to reduce purchase friction.

Implementing Customer Support Systems

Your support system must be responsive and scalable. Offer support through multiple channels and train your staff to be true product experts who can help with everything from fit guidance to prescription questions. Monitoring your support metrics allows you to continuously improve your service quality.

Systematizing Customer Feedback

Actively collect customer feedback through post-purchase surveys and review requests. This feedback is an invaluable source of insights for product development and service improvements. Responding to reviews—both positive and negative—shows you’re listening and helps manage your brand’s reputation.

Optimizing Post-Launch Business Operations

Continuous optimization is what drives efficiency and profitability as you scale. This requires a data-driven approach to managing every aspect of your business, from inventory to marketing.

Implementing Inventory Management

A robust inventory system helps you balance the costs of holding stock with the need to have products available for your customers. Use demand forecasting based on sales data and seasonal trends to prevent stockouts and avoid costly overstock situations.

Analyzing Sales Data and Customer Analytics

Use your sales and customer data to get actionable insights. Analyze which channels are performing best, which products are most popular, and what your customer’s purchase behavior looks like. This data should guide your marketing decisions, product development, and retention strategies.

Planning Future Collections

Your product development should be a continuous cycle guided by trend analysis, customer feedback, and new market opportunities. A structured planning process for future collections ensures you stay relevant and can manage the complex timelines required for design, production, and launch.

Strategically Expanding into New Markets

As you grow, you can explore expansion into new customer segments, geographic markets, or sales channels. Each expansion opportunity requires careful analysis of the market, the competition, and any new regulatory hurdles. Strategic expansion allows you to grow sustainably while maintaining your operational quality.

Conclusion

Building a standout eyewear brand is a marathon, not a sprint. It demands integrating sharp market strategy with technical precision and the right manufacturing partnership. Your advantage comes from a systematic approach to product, quality, and operations. To turn your vision into a profitable reality that delights customers, you need a partner with proven quality and technical expertise. Let’s build something exceptional together.

Frequently Asked Questions

1. What are the trade-offs between handmade acetate and 3D-printed nylon?

Italian handmade acetate provides a superior, rich aesthetic and a traditional luxury feel but comes at a significantly higher cost and has longer production times. 3D-printed nylon offers incredible design freedom and less waste, but its finish currently lacks the premium quality that luxury consumers typically expect.

2. How does a manufacturer’s lens sourcing affect the final product?

Manufacturers with in-house lens coating capabilities offer better quality control over specialized treatments. Those with strong sourcing relationships with premium lens suppliers like Carl Zeiss can provide access to advanced materials that meet high-impact standards like ANSI Z87.1+. The best choice depends on whether you prioritize integrated production or a wider range of material options.

3. How can I verify a manufacturer’s sustainability claims?

To verify claims about materials like bio-acetate, you must ask for documentation. This includes material certifications, supply chain traceability records, and third-party audits. You should also request specific data on recycled content, biodegradability, and visit the facility to see their environmental management systems firsthand.

4. What is the difference between an OEM and an ODM partnership?

An OEM (Original Equipment Manufacturer) partnership is ideal if you have a strong, unique design vision, as you maintain full creative control while the partner handles production. An ODM (Original Design Manufacturer) partnership is faster, as you customize a manufacturer’s existing designs, but it offers less differentiation.

5. What are the most critical clauses for a manufacturing agreement?

Beyond MOQs and lead times, your agreement must include clauses on intellectual property ownership, confidentiality, and exclusive territory rights to protect your design. Also, specify detailed quality tolerances, testing protocols, and clear penalties for failing to meet quality or delivery standards to ensure accountability.