Custom Glasses Frames Premium Materials Guide

Custom glasses frames are powerful brand differentiators that transform your positioning, customer perception, and profitability. The premium eyewear segment is growing, driven by consumer demand for personalization and an appreciation for superior craftsmanship. Your material choices are the foundation of this success, directly impacting your brand’s perceived value and the loyalty of your customers.

Phase 1: Defining Your Position in the Premium Market

Why Premium Materials? Understanding Core B2B Success

Premium materials are the foundation of any successful custom eyewear collection. They directly impact your brand’s value, customer satisfaction, and long-term profitability. The difference between standard and premium materials translates into measurable business outcomes: superior brand perception, higher margins, and fewer warranty claims.

The premium eyewear market operates on principles different from the mass market. Premium buyers evaluate the total cost of ownership, which includes durability, comfort, and brand prestige. High-end materials like Italian Mazzucchelli acetate, medical-grade titanium, and ethically sourced buffalo horn justify higher margins by delivering the quality benchmarks discerning customers demand.

Material choice also dictates your supply chain efficiency. Premium materials offer superior workability, allowing for the intricate designs and thinner profiles that set your products apart. These materials typically come from established suppliers with consistent quality standards, reducing production variability and ensuring reliable delivery schedules.

Differentiating Your Brand: “Custom,” “Bespoke,” & “Made-to-Order”

You must understand the nuances between customization levels to position your brand and set pricing strategies. These distinctions directly impact your material needs, production processes, and target customer.

| Level | Description | Material Focus | Target Model |

| Custom | Modifications to existing frame designs, such as color changes, size adjustments, or logo placement. | Flexible and readily available materials like standard acetate and metals offer the best cost-performance ratio. | Lowest barrier to entry; allows for reasonable production volumes. |

| Made-to-Order | Predetermined design options are combined with individual sizing and finishing for each customer order. | A balance of unique and reliable materials, including premium acetates and specialized metal alloys. | Balances customization appeal with production efficiency; ideal for scaling a premium brand. |

| Bespoke | A completely unique design is created from scratch based on an individual’s measurements and specifications. | Requires deep material expertise and access to exotic materials like buffalo horn, precious metals, or limited-edition acetates. | Highest level of personalization; commands top-tier pricing but demands flexible manufacturing. |

Pinpointing Your High-Value Customer

Your material selection must align with the specific preferences, lifestyle, and buying motivations of your target customer. Different segments prioritize distinct material characteristics.

The Luxury Fashion Aficionado

Luxury customers prioritize exclusivity, craftsmanship, and brand heritage. Your material choices must have a rich story. This includes Italian Mazzucchelli acetate, with its 170-year history, or precious metals like 18-karat gold and platinum.

Best Practice: Use materials that guarantee uniqueness. Buffalo horn, for instance, offers patterns that ensure no two frames are identical, appealing directly to a customer’s desire for an exclusive accessory. Hand-finishing techniques are not optional; they are required to add the artisanal value this segment expects.

The Performance Athlete

Performance-focused customers value functional benefits above all else. Your materials must enhance performance through reduced weight, increased durability, and superior resistance to the elements.

Titanium is the premier material for this segment due to its exceptional strength-to-weight ratio, corrosion resistance, and hypoallergenic properties. For even greater flexibility, you should specify beta-titanium. Advanced polymers like TR-90 offer impact resistance and flexibility that traditional materials cannot match. Carbon fiber remains the cutting edge, offering immense strength at an ultra-lightweight profile.

The Eco-Conscious Millennial

Environmental consciousness drives purchasing decisions for this segment. You must provide transparency in material sourcing, production, and end-of-life options.

Bio-based acetates are the most accessible sustainable option, replacing petroleum-based plasticizers with plant-derived alternatives. For a more compelling story, advanced recycled materials like composites made from ocean-bound plastic offer performance parity with virgin materials. Natural options like bamboo and responsibly sourced wood have a strong aesthetic appeal that resonates with this buyer.

The Boutique E-commerce Buyer

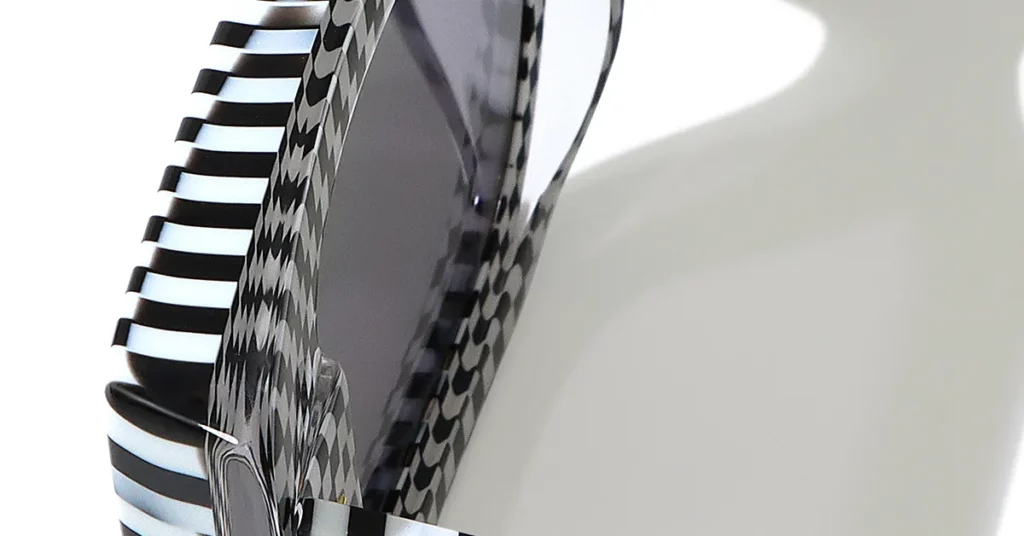

Digital-native customers prioritize visual impact for social media. Your materials and finishes must be photogenic and offer distinctive visual traits.

For this segment, you need specialty acetates with complex patterns, gradient effects, and unique colorations. Mazzucchelli’s premium acetates provide unmatched color depth that markets well digitally. For metal frames, specify finishes like PVD coatings, anodizing, or laser etching to create a contemporary aesthetic.

Translating 2025 Market Trends into Product Strategy

Industry forecasts for 2025 reveal key trends that must inform your material selection. Proactive product development based on these trends will capture emerging market opportunities.

- Sustainable Materials Dominance: Sustainability is no longer a niche. Bio-based acetates, recycled metals, and innovative composites will become standard offerings. You must integrate them into your core collection.

- Smart Integration: The incorporation of electronics requires materials that can house components without disrupting the aesthetic. This trend favors lightweight, non-conductive materials like advanced polymers.

- Geometric Sophistication: A trend toward complex, architectural forms demands materials with superior workability. This gives an edge to high-grade acetates and precision-machined metals.

- Ultra-Lightweight Innovation: The demand for all-day comfort drives the need for ultra-lightweight materials. Your focus should be on advanced titanium alloys, specialized polymers, and carbon fiber composites.

Building a Compelling Business Case for Your Collection

Calculating ROI: Balancing Material Costs & Target MSRP

Premium material selection requires rigorous financial analysis. You must understand how higher material costs translate into perceived value and a customer’s willingness to pay more.

Premium materials can carry 20-50% higher costs than standard alternatives. However, this investment enables retail price premiums of 100-300% when positioned correctly. For instance, Italian Mazzucchelli acetate costs roughly 30% more than standard acetate but can easily double the final retail price of the frame.

The Bottom Line: Your calculation must extend beyond direct costs. Premium materials offer superior durability, which reduces warranty claims and customer service overhead. They attract customers with a higher lifetime value who are less sensitive to price, fundamentally improving your profitability over the long term.

Leveraging “Country of Origin” as a Quality Signal

Geographic origin carries powerful quality associations that influence customer perception and justify premium pricing. You must use these associations to your advantage in sourcing strategies.

| Origin | Reputation & Association | Key Materials & Expertise | Strategic Value for Your Brand |

| Italy | Luxury craftsmanship, fashion leadership, and artisanal heritage. | Mazzucchelli acetate, hand-finishing techniques, bold design. | Adds significant perceived value and a story of provenance. Ideal for high-fashion and luxury collections. |

| Japan | Technical excellence, precision manufacturing, and attention to detail. | High-grade titanium, beta-titanium, technically superior acetates, minimalist design. | Appeals to performance and luxury segments that value flawless consistency and quality control. |

| Germany | Precision engineering and technical innovation. | Stainless steel, advanced hinge technology, functional and durable components. | Appeals to performance-oriented customers who value technical superiority and durability. |

The Strategic Importance of Lens Technology

While the frame commands visual attention, lens technology drives customer satisfaction. Premium frame materials are the necessary foundation for the advanced lens technologies that complete your value proposition.

High-quality frame materials like acetate and titanium maintain the dimensional stability required for precise lens mounting. This is non-negotiable for progressive and high-prescription lenses. A stable frame is the only way to deliver the full benefit of advanced lens coatings, blue light filters, and photochromic technologies.

Phase 2: The Architect’s Toolkit—A Premium Material Deep Dive

Palette 1: Advanced Polymers—The Foundation of Modern Design

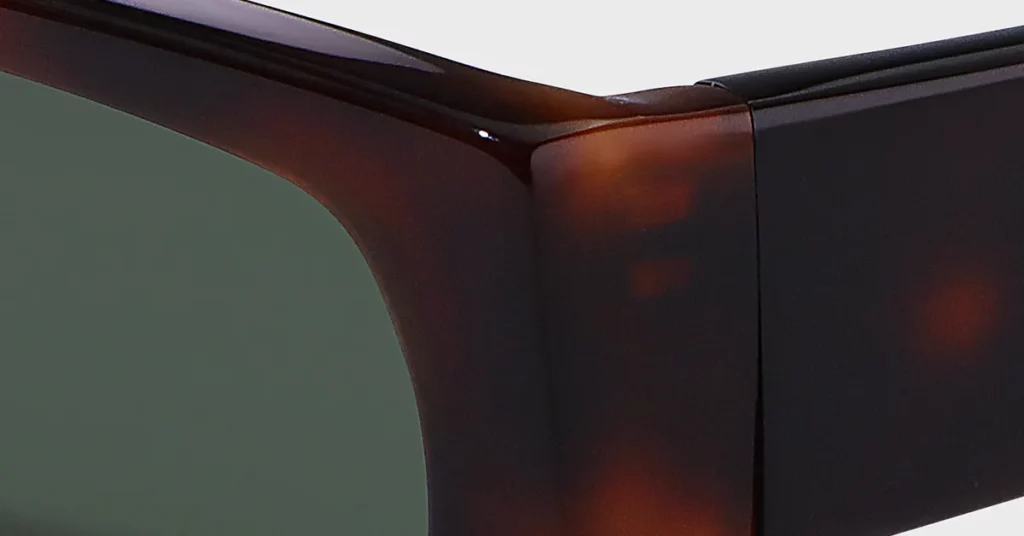

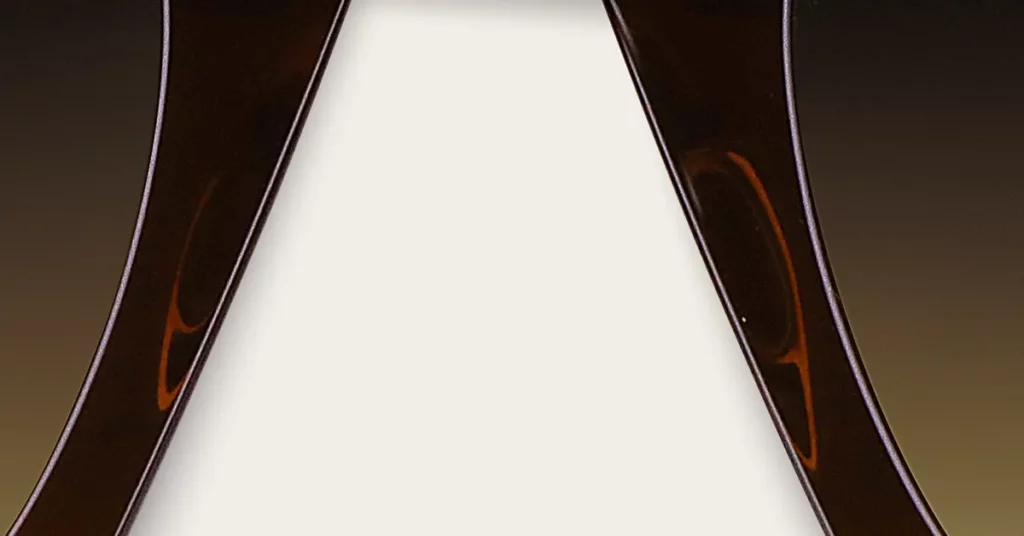

Cellulose Acetate (Zyl): Unmatched Color & Artisanal Appeal

Cellulose acetate is the gold standard for premium eyewear, offering unmatched aesthetic flexibility. This plant-based polymer, derived from wood pulp and cotton fibers, is the ideal canvas for luxury collections.

Definition: In high-quality cellulose acetate, color is embedded throughout the material, not applied to the surface. This process, known as block production, ensures color permanence and creates a visual depth impossible to achieve with paint or prints, clearly distinguishing your product from mass-market alternatives.

Acetate’s thermoplastic properties allow opticians to achieve a perfect fit through careful heating and forming. This adjustability is a significant competitive advantage for custom eyewear, as you can fine-tune frames to individual facial structures without compromising the material’s integrity.

Sourcing: Italian (Mazzucchelli) vs. Japanese Acetate

Your sourcing decision impacts brand positioning, customer perception, and operational capability. The choice between Italian Mazzucchelli and Japanese acetate is a strategic one.

| Attribute | Italian Mazzucchelli Acetate | Japanese Acetate |

| Key Strength | Unparalleled color depth and pattern complexity. | Exceptional consistency and quality control. |

| Brand Story | A 170-year heritage of innovation and luxury fashion association. | Reputation for technical performance and reliability. |

| Best For | Luxury and fashion-forward collections where unique aesthetics justify premium pricing. | Precision applications and high-volume production where reliability is paramount. |

| Customization | High flexibility for developing unique colors and exclusive patterns. | More standardized offerings, focused on quality over bespoke patterns. |

| Supply Chain | Longer lead times are common, but technical support for custom work is superior. | More predictable delivery schedules and highly consistent material quality. |

Key B2B Properties of Cellulose Acetate

- Hypoallergenic Nature: Acetate rarely causes allergic reactions, giving your products broader market appeal and reducing customer service issues related to skin sensitivity.

- Hand-Polishing Capability: The material’s response to hand-polishing creates a mirror-like finish and tactile warmth that communicates artisanal quality. This finish is a key differentiator from cold metal alternatives.

- Fit Adjustability: As a thermoplastic, acetate can be precisely adjusted by an optician. This is a crucial advantage for bespoke and made-to-order collections where a perfect fit is the ultimate measure of success.

Performance Nylons (TR-90) & Fortisan

Advanced polymer engineering has produced specialized materials that excel in performance applications. These materials offer unique combinations of flexibility, durability, and low weight for specific market segments.

TR-90, a Swiss thermoplastic, offers exceptional durability and flexibility that far exceeds traditional acetate. Its ability to bend without breaking makes it the ideal material for sports applications and active lifestyles where impact resistance is a primary requirement. Fortisan and similar high-performance polymers offer superior chemical resistance and environmental stability.

The Business Case for Sportswear and Performance Brands

Performance polymers allow your brand to target market segments that traditional materials cannot serve. The sports and active lifestyle markets prioritize function, creating clear opportunities for materials that excel in performance metrics.

The Bottom Line: The flexibility of TR-90 and similar materials dramatically reduces breakage rates compared to acetate. This directly lowers your warranty costs and increases customer lifetime value. You can command price premiums by emphasizing the functional benefits that directly improve the user experience.

Technical Advantages of Performance Nylons

- Chemical Resistance: These materials maintain their appearance and structural properties despite exposure to aggressive chemicals, oils, and sweat.

- Lightweighting: The reduced density of performance nylons enhances wearer comfort and can lead to lower material usage and shipping costs.

- Resilience: High-performance polymers maintain their properties across wide temperature ranges and resist degradation from UV exposure.

Palette 2: High-Performance Metals—Forging Strength & Precision

Titanium vs. Stainless Steel: A Cost-Benefit Analysis

Your choice of metal requires a careful evaluation of performance, cost, and market positioning. The decision between titanium and stainless steel is a strategic trade-off.

| Attribute | Titanium | Stainless Steel |

| Performance | Superior strength-to-weight ratio, completely corrosion-proof, and hypoallergenic. | Good strength, high corrosion resistance, and excellent workability. |

| Cost | Significantly higher material cost. | More economical; provides an accessible entry to premium metal frames. |

| Manufacturing | Requires specialized equipment (e.g., vacuum welding) and expertise. | Easier to machine, weld, and finish using standard processes. |

| Ideal For | Ultra-luxury, high-performance, and minimalist designs where lightweight strength is paramount. | Fashion-forward and cost-conscious premium collections requiring thin, elegant profiles. |

| Brand Story | High-tech, medical-grade, and aerospace-derived precision. | Durable, reliable, and classic engineering. |

Pure Titanium & Beta-Titanium

Pure titanium is the pinnacle of eyewear materials, offering an unmatched combination of strength, lightness, and biocompatibility. Its hypoallergenic properties make it suitable for every customer, eliminating any risk of metal sensitivity.

Best Practice: For designs requiring more flexibility, you must specify beta-titanium. This alloy, which includes small amounts of aluminum and vanadium, enables thinner frame cross-sections and more complex geometries while retaining titanium’s core strength and lightweight advantages. The manufacturing of titanium frames requires advanced techniques, creating a barrier to entry that protects your margins.

Stainless Steel: A Gateway to Premium Metal Aesthetics

Stainless steel provides an accessible entry into premium metal aesthetics without the cost premium of titanium. Its inherent strength and corrosion resistance enable the thin, elegant designs that appeal to style-conscious consumers.

Modern surgical-grade stainless steel alloys are often nickel-free, addressing the allergy concerns that previously limited the adoption of metal frames. This hypoallergenic property expands your potential market. The material’s workability allows for precision welding and intricate forming, supporting sophisticated designs while maintaining manufacturing efficiency.

Aluminum & Monel: Niche Metals for Specific Designs

Leveraging Aluminum for Modernist Aesthetics

Aluminum offers a distinctive, contemporary look that appeals to customers seeking a high-tech aesthetic. Its natural surface finish and response to anodizing enable unique visual effects that can differentiate your product in a crowded market. It is also exceptionally lightweight, and its thermal properties provide comfort in varying climates.

Understanding Monel: Malleability vs. Nickel Allergy

Critical Warning: Monel, a nickel-copper alloy, offers excellent malleability for intricate designs at a lower cost. However, its high nickel content can cause severe allergic reactions in sensitive individuals, significantly limiting its market application. While protective coatings can mitigate this risk, you must be transparent about the material’s composition.

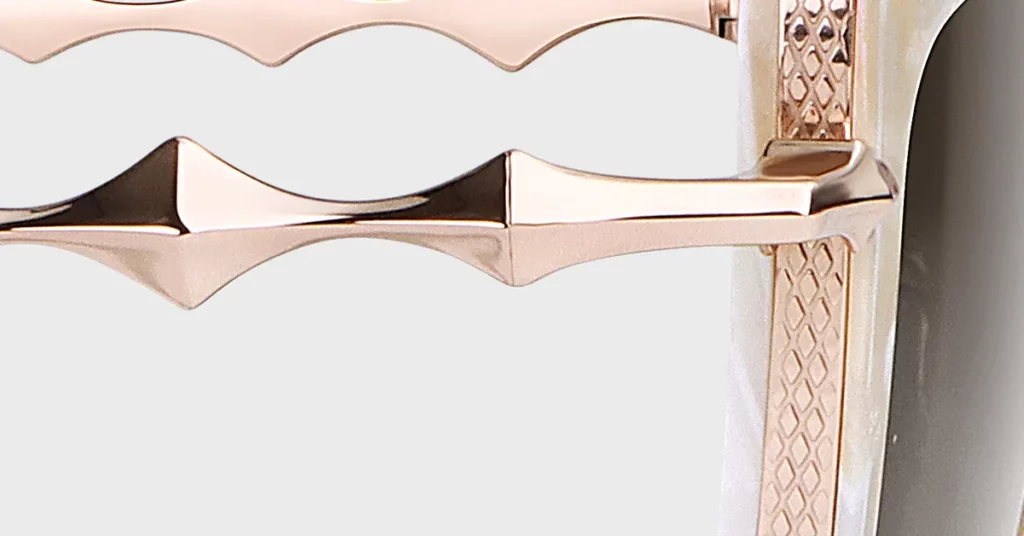

Precious Metals (Gold, Platinum): The Ultra-Luxury Segment

Precious metals are the ultimate expression of luxury in eyewear. They command extreme price premiums but offer exceptional profit margins for brands that can execute correctly.

18-karat gold provides the optimal balance of purity and workability for eyewear applications. Platinum offers even greater exclusivity due to its rarity and durability. In my two decades crafting handmade eyewear, I’ve consistently observed that the manufacturing of precious metal frames is as much about the process as the material. It requires specialized hand-finishing and engraving capabilities to justify the price.

Example: The brand LINDBERG masterfully uses precious metals, combining Greenlandic gold with top-grade diamonds. This strategy illustrates how material provenance, quality, and craftsmanship combine to create the ultimate luxury positioning.

Palette 3: Natural & Exotic Materials—Creating Unique Narratives

Buffalo Horn: The Ultimate in One-of-a-Kind Luxury

Buffalo horn is the pinnacle of natural materials for luxury eyewear. It offers unique patterns that ensure no two frames are ever identical. This exclusivity is a powerful selling point for customers seeking a distinctive accessory that cannot be mass-produced.

Key Selling Points of Buffalo Horn

- Unique Patterning: Each piece of horn has a unique grain, color, and translucency. This natural variation is a marketing advantage, emphasizing the artisanal craftsmanship of each frame.

- Lightweight Comfort: Horn is exceptionally light and adapts to the wearer’s body temperature, providing a comfortable experience that distinguishes it from metal or plastic.

- Warm, Tactile Feel: The sensory experience of polished horn reinforces its luxury positioning. Its natural depth and luster communicate a quality that resonates with discerning customers.

Supply Chain Challenge: Ethical Sourcing & Craftsmanship

Critical Warning: Sourcing buffalo horn requires strict attention to ethics and sustainability. You must demand proof of responsible sourcing from controlled, non-endangered species (typically the Asian water buffalo) to support conservation efforts and protect your brand’s reputation. Working with horn requires master craftspeople, limiting supplier options and increasing costs.

Wood & Bamboo: The Eco-Conscious & Natural Aesthetic

Wood and bamboo appeal to environmentally conscious consumers while offering a distinctive aesthetic. These materials combine sustainability with unique visual and tactile properties.

Technical Consideration: Lamination for Durability

Natural wood requires careful engineering to achieve the durability needed for eyewear. Lamination, a process of bonding multiple thin wood layers with specialized adhesives, is key. This creates a composite material that far exceeds the strength of solid wood.

Best Practice: Use the lamination process to create unique design possibilities. You can specify contrasting wood species, embed thin metal layers for strength, or create complex geometries that are impossible with solid materials. This supports innovative designs that justify premium pricing.

Bio-Acetates & Recycled Polymers: Marketing Sustainability

Sustainable materials provide a strong marketing advantage, but authentic claims require verifiable sourcing and transparent production.

Verifying Claims: Certifications to Demand

Best Practice: To protect your brand from accusations of “greenwashing,” you must demand robust verification from your supply chain. Do not accept a supplier’s word.

- Require third-party certifications for renewable content (e.g., confirming a bio-acetate is made from at least 70% bio-based sources).

- Ask for a carbon footprint analysis that compares the material to its virgin alternative.

- Demand documentation on end-of-life recyclability and transparent reports on the entire supply chain.

Phase 3: From Blueprint to Reality—Mastering Manufacturing

Selecting Your Production Philosophy

Your production method fundamentally impacts product characteristics, cost, and market position. You must understand the trade-offs between traditional craftsmanship and digital manufacturing.

| Philosophy | Core Method | Key Benefits | Best For |

| Traditional Craftsmanship | Hand-polishing, riveting, traditional assembly, and individual adjustment by skilled artisans. | Creates unique character, artisanal appeal, and superior surface finishes. | Justifying premium pricing for luxury goods where human touch is a key value proposition. |

| Digital Manufacturing | CNC machining, 3D printing (additive manufacturing), and automated assembly. | Unmatched precision, geometric complexity, consistency, and rapid prototyping. | Performance eyewear, intricate designs, and achieving consistent quality across large production runs. |

The Case for Subtractive Manufacturing: CNC Milling

CNC (Computer Numerical Control) milling provides exceptional precision and surface finish. This subtractive process removes material from a solid block to achieve exact dimensions.

Example: CNC machining is the ideal method for showcasing the beauty of layered acetate. The precise cutting process cleanly reveals the embedded colors and patterns, creating sharp transitions that maximize visual impact. It is also highly effective for shaping horn, accommodating natural variations while achieving consistent wall thickness.

The Case for Additive Manufacturing (3D Printing)

3D printing enables complex geometries and rapid design iteration that are impossible with traditional methods. The additive process builds parts layer-by-layer, allowing for internal features and complex forms from a single piece of material.

Key Technologies: Evaluating SLS vs. MJF for Production

For production-grade frames, you will choose between Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). Your choice has implications for cost, speed, and finish.

| Technology | Process | Surface Finish | Speed | Ideal Use Case |

| SLS | A laser sinters powdered material layer by layer. | Good, with a slightly grainy texture that often requires post-processing. | Slower process. | Low-to-mid volume production; proven technology with a wide range of materials. |

| MJF | An inkjet array applies fusing and detailing agents, which are then fused by heat. | Superior, smoother finish with better fine-detail resolution. | Faster process. | Higher volume production where speed and superior surface quality justify the investment. |

Material Focus: Polyamide (PA11, PA12) Powders

Polyamide powders are the workhorse of 3D-printed eyewear, offering excellent strength, flexibility, and chemical resistance. PA11 is bio-based (derived from castor beans) and offers superior flexibility. PA12 is a synthetic that provides enhanced strength and dimensional stability. Modern dyeing and finishing options for polyamides now allow for aesthetic customization that approaches traditional materials.

The Irreplaceable Value of Hand Craftsmanship

Despite technological advances, hand craftsmanship is still required to achieve the highest levels of quality and justify a premium price. Skilled artisans provide a level of detail and quality assessment that no machine can replicate.

Best Practice: You must combine digital precision with human touch. Use CNC milling or 3D printing for the initial shaping, but specify hand-polishing for the final finish. An artisan’s ability to respond to the unique characteristics of acetate or horn creates a surface depth that machines cannot match.

Deconstructing the Frame: High-Quality Components

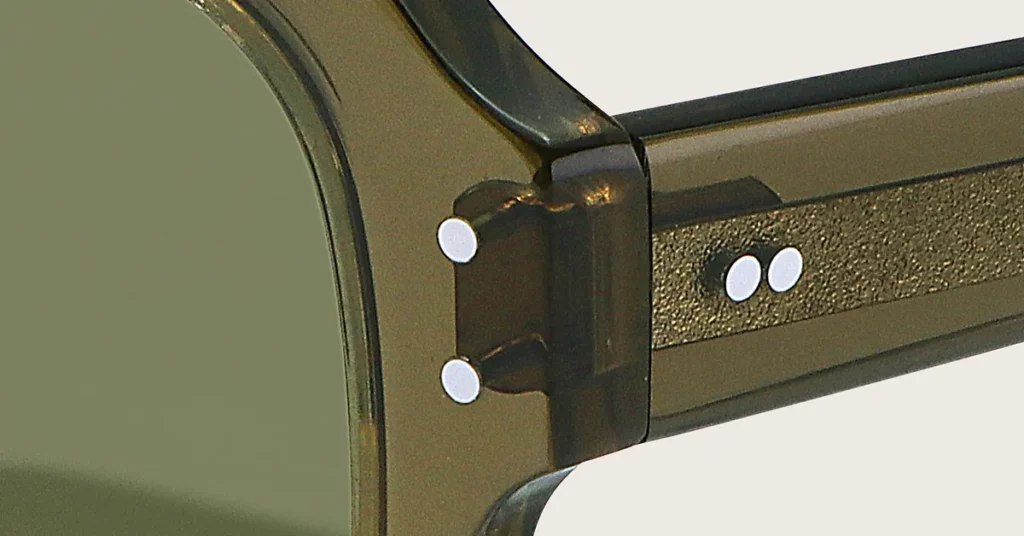

Hinge Integrity: Screwless & Custom Hinge Designs

The hinge is a critical component that directly impacts durability and customer satisfaction. A premium hinge is a clear mark of quality. Spring hinges offer enhanced comfort and reduce stress on the frame, while screwless designs eliminate a common failure point and provide clean, modern aesthetic lines.

The Nuances of Finishing: From Material to Luxury Product

Surface finishing transforms raw materials into a luxury product. Premium techniques require specialized equipment and skilled operators but add significant value.

Metal Finishes for Brand Differentiation

- PVD Coating: Physical Vapor Deposition provides superior durability and unique color options compared to standard plating.

- Anodizing: This electrochemical process creates a hard, protective surface on aluminum that can be vibrantly colored.

- Laser Etching: Enables precise, permanent marking for branding or decorative effects without compromising the material.

Acetate Finishes: Barrel Tumbling vs. Hand-Polishing

| Finishing Method | Process | Result | Perceived Value |

| Barrel Tumbling | Frames are tumbled in barrels with abrasive media and polishing compounds. | A consistent, uniform, and cost-effective basic polish. | Good. Suitable for large-scale production but lacks artisanal refinement. |

| Hand-Polishing | A skilled artisan uses polishing wheels and compounds in multiple stages. | A superior, mirror-like finish with exceptional depth, luster, and warmth. | Luxury. The tactile quality and flawless finish clearly communicate a premium product. |

Achieving the Perfect Fit: Strategic Customization

Fit quality directly impacts customer satisfaction. Premium customization options for the temple, nose pads, and bridge are a key competitive advantage.

Pro Tips: Leverage 3D facial scanning technology to offer bespoke, data-driven ergonomics. This technology allows you to create frames that are perfectly optimized for an individual’s facial characteristics. Integrating this data directly with your CNC or 3D printing manufacturing systems enables a seamless mass-customization process that justifies a significant price premium.

Phase 4: Vetting Your Manufacturing Partner

Evaluating a Supplier’s Technical Proficiency

Your choice of supplier directly impacts product quality and brand reputation. A comprehensive evaluation process is non-negotiable.

The Material Audit: How to Assess a Partner’s Expertise

You must assess a partner’s true expertise with your chosen materials. They must demonstrate competency in handling, processing, and finishing.

- Demand samples made from your specific materials.

- Request documentation of their quality control processes for those materials.

- Verify their certifications and process controls.

From Render to Reality: A Checklist for Prototypes

Prototype evaluation provides crucial insight into a supplier’s capabilities.

- Visual Inspection: Scrutinize surface finish, color consistency, dimensional accuracy, and overall craftsmanship.

- Functional Testing: Evaluate hinge durability, frame flexibility, and joint strength. The prototype must survive simulations of real-world use.

Differentiating Supplier Tiers

| Supplier Type | Role & Capabilities | Strengths | Weaknesses |

| Factory | High-volume production with established processes and quality systems. | Cost advantages for large orders, predictable output. | Lacks flexibility for custom work, slower to adapt. |

| Studio | Focuses on craftsmanship, customization, and smaller production runs. | Excels at premium, bespoke, and complex work. | Limited scalability, higher per-unit cost. |

| Sourcing Agent | A third-party that coordinates with multiple factories and suppliers. | Market knowledge, supply chain management. | Adds a layer of cost and communication complexity. |

Aligning on Business Models and Mitigating Risks

Partnership Structure: Private Label vs. White Label

| Model | Description | IP Ownership | Your Investment |

| Private Label | You provide the designs and specifications; the partner manufactures exclusively for you. | You own the intellectual property. | Highest. Requires full development, marketing, and inventory costs. |

| White Label | You choose from the manufacturer’s existing designs and apply your brand. | The manufacturer owns the design IP. | Lowest. Faster market entry with minimal development cost. |

| Co-Development | You and the manufacturer collaborate on a new design, sharing costs and risks. | IP ownership is negotiated. | Medium. Combines capabilities but requires careful legal agreements. |

Financial & Logistical Hurdles: MOQs and Lead Times

Critical Warning: You must navigate Minimum Order Quantities (MOQs) and lead times carefully. Premium materials often have higher MOQs and longer lead times. This will impact your cash flow and inventory management. You must build these factors into your business model from day one to ensure financial viability.

Protecting Your Vision: Securing Intellectual Property

A comprehensive IP strategy is essential.

- File for design patents to protect unique aesthetic elements in your key markets.

- Use confidentiality agreements (NDAs) with all partners to protect proprietary information.

- Register your trademarks to protect your brand name and logo.

Final Due Diligence: Verifying Quality and Compliance

The On-Site Factory Audit: A Non-Negotiable Step

An on-site factory audit is the only way to verify a potential partner’s capabilities.

- Quality System: Evaluate their documentation, process controls, and testing equipment.

- Operational Assessment: Inspect the equipment, assess workforce qualifications, and check facility conditions. A modern, clean facility indicates a commitment to quality.

Compliance Check: Demanding Proof of International Standards

Your supplier must prove adherence to relevant international standards to ensure market access and protect you from liability.

- Quality Management: Demand to see their ISO 9001 certification.

- Product Safety: For the US market, they must provide proof of compliance with ANSI Z80.3 safety standards for eyewear.

Conclusion

Market-leading custom eyewear is born from a strategic synthesis of product vision, deep material knowledge, and a meticulously vetted manufacturing partner. This dual focus is the only path to success in the competitive premium market. The convergence of material science and manufacturing excellence creates the sustainable competitive advantage that drives profitability and brand leadership.

Frequently Asked Questions

1. How does the choice between titanium and acetate impact design potential?

Titanium offers superior strength for intricate mechanical details and ultra-thin profiles. High-grade cellulose acetate provides unmatched color depth, complex patterns, and the ability to embed designs directly into the material, offering limitless aesthetic variation.

2. For a luxury brand, what are the trade-offs between an Italian workshop and a German 3D printing firm?

An Italian workshop provides artisanal heritage, hand-finishing excellence, and a story that supports luxury pricing. A German 3D printing firm offers unparalleled design freedom for complex geometries and perfect consistency, appealing to a customer who values technical innovation over tradition.

3. What durability tests should I request from a potential manufacturing partner?

Demand cyclic hinge testing (min. 25,000 cycles), drop tests, temple flexibility tests, and thermal cycling. Also require testing for corrosion resistance, spring hinge fatigue, and stress tests at critical weld or joint points to simulate real-world failure modes.

4. What finishing processes create a true luxury product?

Multi-stage hand-polishing of acetate creates a mirror-like finish with a depth that machines cannot replicate. For 3D prints, vapor smoothing achieves an injection-molded quality surface. For metals, PVD coating provides durable, unique colors that surpass standard plating.

5. What documentation is needed to prove a supplier’s sustainability claims?

Demand third-party certifications for renewable content (e.g., bio-based percentage), a comparative carbon footprint analysis, and proof of end-of-life recyclability. Require full supply chain transparency reports to protect your brand against claims of greenwashing.