For E-commerce Brands: The Playbook for Building a Scalable and Profitable D2C Supply Chain

Building a profitable D2C supply chain requires a systematic, four-phase framework. You must first architect a financial and strategic blueprint, then build a core operational engine for fulfillment and returns. Next, deploy an integrated technology stack for visibility. Finally, use data analytics to scale operations, improve long-term profitability, and continuously optimize for efficiency and customer experience. This structured approach is fundamental to achieving sustainable growth.

Phase 1: Architecting the Strategic & Financial Blueprint

Your go-to-market strategy is the foundation of your supply chain. It must articulate why customers should buy directly from you, because this rationale dictates your operational and financial structure. A clear strategy is what separates brands that achieve sustainable growth from those that fail.

Defining Your D2C Go-to-Market Strategy

Direct customer relationships are your most valuable asset because they provide unparalleled access to first-party data. This data allows you to build predictive models for demand and personalization, which directly translates to higher margins and customer loyalty.

- Key Metric: Brands with strong first-party data strategies achieve 20-30% higher customer lifetime values compared to those relying on third-party retail partners.

- Adopting a D2C model gives you full control over your brand’s messaging, pricing, and packaging. This control is your primary tool for creating a cohesive brand experience that reinforces your value proposition and differentiates you from competitors.

- You must conduct a thorough market assessment. Customer acquisition costs (CAC) have risen dramatically, with some sectors seeing a 300% increase since 2019. Brands that fail to accurately model total CAC, including marketing and service costs, will face unsustainable unit economics.

- The tension between growth and profitability has destroyed many D2C brands. You must balance aggressive growth with disciplined unit economics. A profitable D2C brand should follow a “Rule of 40” approach, where your revenue growth rate plus your profit margin exceeds 40%.

- Best Practice: Establish clear profitability milestones tied to volume. For example, target a 15% net margin at $10 million in annual revenue, with specific improvement targets as you scale.

Selecting the Right Operational Fulfillment Model

Your fulfillment model directly impacts costs, customer satisfaction, and scalability. The choice between in-house, 3PL, hybrid, or dropshipping depends entirely on your product, volume, and capital. You must analyze these trade-offs to select the structure that aligns with your financial plan.

| Fulfillment Model | Capital Expenditure | Operational Control | Scalability | Best For |

| In-House | High | Maximum | Low to Medium | Brands with >$5M annual revenue, sufficient volume for economies of scale, or products requiring specialized handling. |

| Third-Party (3PL) | Low | Low to Medium | High | Brands seeking rapid growth without high capital investment; allows focus on core business activities like marketing and product. |

| Hybrid | Medium | Strategic | Medium to High | Brands balancing cost optimization with control, often using a 3PL for standard items and in-house for high-value or custom products. |

| Dropshipping | Very Low | Minimal | High | Testing new products or markets with minimal inventory risk. Not suitable for premium brand positioning due to lack of control. |

- Pro Tips: Evaluate any 3PL provider based on their technology stack, geographic footprint, and experience with your specific product category. Demand detailed Service Level Agreements (SLAs) and establish clear performance metrics from day one.

- Critical Warning: Dropshipping rarely supports a premium brand. The longer delivery times and inconsistent packaging quality that come from a lack of control will damage your brand’s reputation and customer trust.

Building the Financial Framework for Profitability

Financial planning is the cornerstone of a sustainable D2C operation. You must develop comprehensive models that account for every cost driver, because this is the only way to make data-driven decisions that protect your margins.

- Calculate True Landed Cost: You must look beyond the factory price. True landed cost includes all expenses to get a product to the customer: freight, duties, fulfillment, packaging, and customer service. This is the only way to make accurate pricing decisions.

- Key Metric: For successful D2C brands, true landed cost typically represents 45-65% of the retail price. Underestimating this will destroy your profitability.

- Project Key KPIs: Your survival depends on tracking the right metrics. You must build dashboards to monitor Cost Per Order, On-Time Delivery percentage, Return Rate by product, CAC, and Customer Lifetime Value in real time.

- Model Shipping Policies: Your shipping policy directly impacts conversion and margin. You must test different models—free, flat-rate, or real-time—to find the balance between customer expectation and profitability.

- For Example: A successful apparel brand offered free shipping on orders over $75. This policy increased their average order value by 35% while maintaining profitable margins, because the higher order value offset the shipping cost and improved inventory velocity.

Phase 2: Building the Core Operational Engine

Effective procurement and inventory management directly impact cash flow and customer satisfaction. The best D2C brands treat inventory as a strategic asset, using sophisticated planning to turn it into a competitive weapon.

Optimizing Procurement and Inventory Management

- Implement Demand Forecasting: You must use advanced demand forecasting to mitigate stockouts and overstocking. Machine learning models incorporate seasonality and market trends, which allows for more accurate inventory allocation and reduces carrying costs.

- Key Metric: Brands with advanced forecasting capabilities achieve inventory turns of 8-12 times annually, compared to 4-6 for brands using basic methods.

- Manage Supplier Relationships: Strategic supplier relationships are a critical asset. You must move beyond transactional interactions to build collaborative partnerships that support innovation and operational excellence, especially when negotiating Minimum Order Quantities (MOQs).

- Analyze Sourcing Impact: Sourcing decisions have a massive impact on your P&L. Near-shoring offers faster delivery and reduced risk at a higher unit cost, while off-shoring provides cost advantages but introduces longer lead times and quality risks. Your decision must be based on total cost of ownership, not just unit price.

- Use Inventory Control Systems: A modern inventory system gives you real-time visibility. You should implement ABC Analysis to prioritize management attention on your most valuable products (A items) while using efficient processes for less critical ones (B and C items).

- Definition: ABC Analysis categorizes inventory by value contribution: A items are high-value and require tight control, B items are moderate-value with standard processes, and C items are low-value with simplified management.

Engineering the Outbound Fulfillment Process

Fulfillment excellence is what separates winning D2C brands from the competition. Every step in your fulfillment process must be engineered for efficiency, accuracy, and a positive customer experience, because this is where your brand promise is either kept or broken.

- Design In-Warehouse Workflow: Your warehouse layout directly impacts processing speed and labor costs. An optimal design minimizes travel time by placing fast-moving items in accessible locations, creating efficient picking paths, and streamlining packing stations.

- Key Metric: Best-in-class warehouse operations achieve 150-200 lines picked per hour with 99.8% accuracy rates by combining optimized workflows with technology.

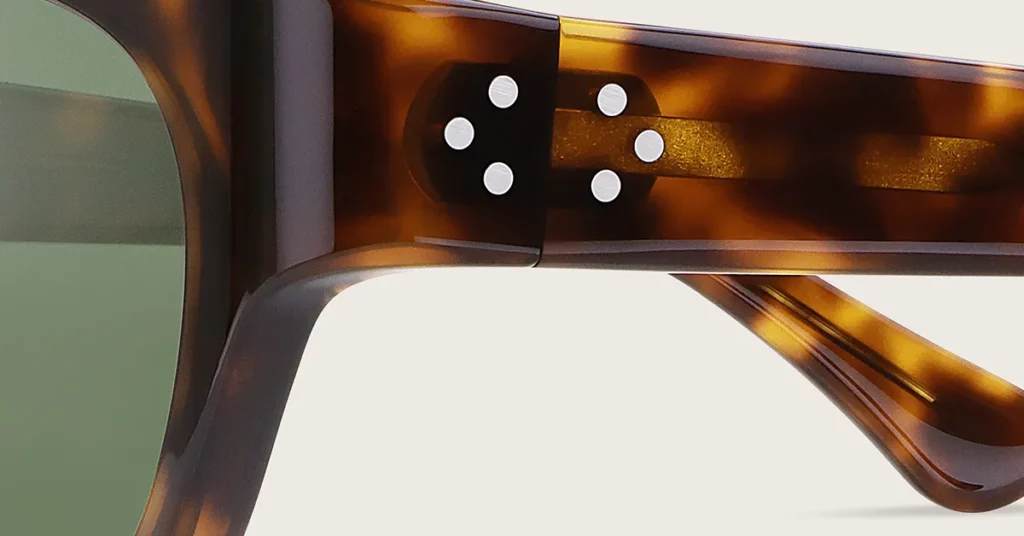

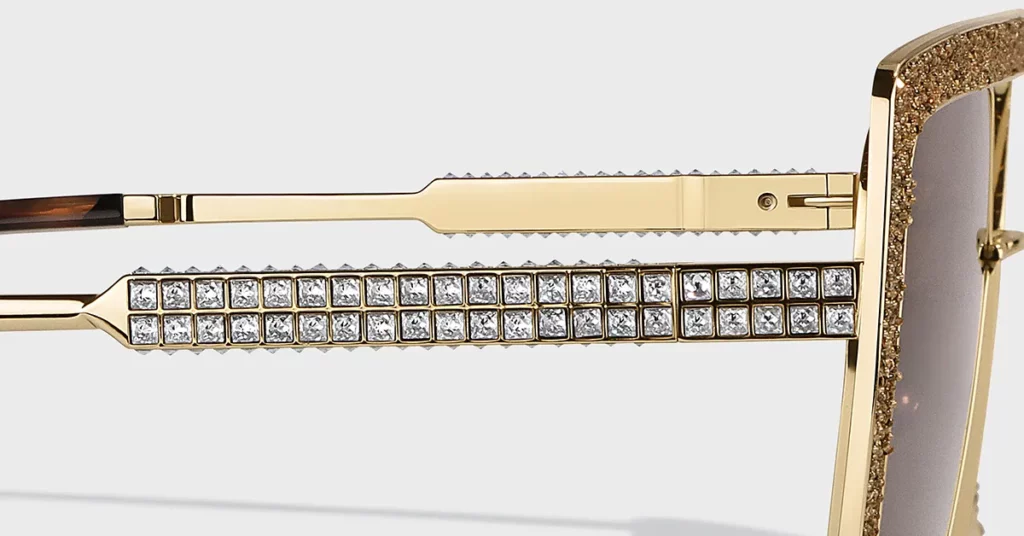

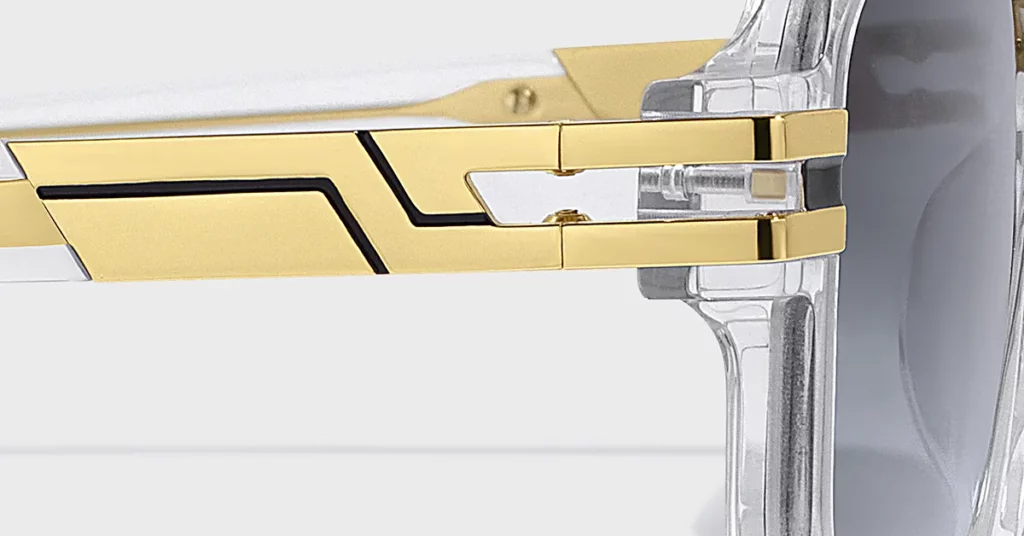

- Create a Memorable Unboxing Experience: Packaging is a critical brand touchpoint. Your packaging strategy must balance brand reinforcement with cost-effectiveness. It is a marketing channel that can reinforce brand values and encourage social sharing.

- For Example: A premium skincare brand increased customer lifetime value by 25% by using custom packaging with product education materials and personalized notes, turning a simple delivery into a memorable experience.

- Choose a Carrier Mix: Your carrier strategy must include a mix of national and regional carriers. This approach allows you to match each shipment type with the most cost-effective and reliable option, reducing costs without sacrificing service quality.

- Mitigate Shipping Cost Volatility: Shipping costs are complex. You must actively manage dimensional (DIM) weight and surcharges. This means optimizing your packaging design to reduce billable weight and negotiating favorable terms based on your shipping volume.

Mastering Reverse Logistics for Customer Retention

Returns management is not just a cost center; it is an opportunity to build customer loyalty. The best brands treat returns as a critical touchpoint that, when handled correctly, can strengthen customer relationships and recover significant value.

- Design a Clear Returns Policy: Your returns policy directly impacts conversion rates. A clear, customer-centric policy reduces purchase anxiety and builds trust. The goal is to balance customer convenience with your own cost management.

- Establish an Efficient Returns Workflow: The efficiency of your returns processing impacts customer satisfaction and operational costs. An effective workflow includes clear receiving procedures, systematic quality inspection, and automated customer communication.

- Key Metric: Best-in-class returns operations process returned items within 24-48 hours of receipt, issuing prompt refunds and keeping the customer informed.

- Define Product Disposition Rules: You must have clear rules for handling returned products to maximize value recovery. Disposition categories include restock, refurbish, liquidate, or dispose. This enables rapid decision-making and minimizes losses.

- Analyze Returns Data: Your returns data is a goldmine of insight into product quality, marketing accuracy, and customer expectations. You must systematically analyze this data to identify and correct the root causes of returns.

- For Example: An athletic wear brand found that sizing inconsistencies were driving 40% of their returns. By improving their online size guides and factory quality control, they reduced returns by 60%.

Phase 3: Deploying the Essential Technology Stack

Your technology stack enables scalable operations and data-driven decision-making. You must build a technology foundation that supports current operations while providing the flexibility for future growth.

Architecting Foundational E-commerce Technology

- The E-commerce Platform: Your e-commerce platform (e.g., Shopify) is the central, customer-facing hub. It must integrate seamlessly with all backend systems. You must evaluate platforms based on their integration capabilities, scalability, and total cost of ownership.

- The Enterprise Resource Planning (ERP) System: An ERP provides a single source of truth by centralizing data management across all business functions. A modern, cloud-based ERP with strong e-commerce APIs is non-negotiable for real-time inventory and financial visibility.

- APIs for Seamless Data Flow: Well-designed API integrations are the connective tissue of your tech stack. They enable real-time data flow between your systems, which eliminates manual work and provides accurate, up-to-the-minute operational visibility.

Implementing Specialized Logistics and Fulfillment Platforms

- Warehouse Management System (WMS): A WMS optimizes warehouse operations through systematic inventory tracking, efficient picking workflows, and labor performance analytics.

- Key Metric: Modern WMS platforms deliver 99.8% inventory accuracy and 30-40% productivity improvements compared to manual systems.

- Order Management System (OMS): An OMS centralizes order processing from all sales channels. It uses intelligent routing to optimize fulfillment and provides a unified view of inventory across your entire network.

- Transportation Management System (TMS): A TMS optimizes shipping by automating carrier selection, finding the best rates, and tracking performance. This directly reduces shipping costs while improving on-time delivery.

- Best Practice: You must choose TMS, WMS, and OMS solutions that integrate tightly to create a seamless, automated workflow from order placement to final delivery confirmation.

Achieving End-to-End Visibility and Control

- Leverage Data Analytics: Advanced analytics provide real-time insight into your supply chain performance. These platforms use predictive modeling to identify bottlenecks and alert you to issues before they impact customers.

- Key Metric: Brands using advanced supply chain analytics typically achieve 15-25% improvements in operational efficiency and a 10-15% reduction in total costs.

- Provide Proactive Shipment Tracking: Proactive communication reduces customer service inquiries. Automated tracking updates and delivery notifications create a positive customer experience while lowering your operational workload.

- For Example: A home goods brand reduced customer service inquiries by 50% by implementing proactive tracking communications and automated delivery notifications.

- Build Resilience with Integrated Technology: A resilient supply chain uses technology to anticipate and respond to disruptions. Your integrated systems must enable rapid responses, such as inventory reallocation or carrier diversification, to maintain service levels during challenging periods.

- Critical Warning: Supply chain disruptions are inevitable. You must build redundancy and flexibility into your systems and processes to maintain operations during a crisis.

Phase 4: Scaling Operations and Maximizing Long-Term Profitability

Data-driven optimization is the engine of continuous improvement. The most successful D2C brands use analytics to guide strategic decisions across every part of the operation, creating a sustainable competitive advantage.

Leveraging Data Analytics for Continuous Improvement

- Track the Perfect Order Percentage: The perfect order percentage is the ultimate metric of supply chain health. It measures orders delivered complete, on time, damage-free, and with accurate documentation. Best-in-class organizations achieve rates above 95%.

- Monitor Inventory Turnover: You must monitor inventory turnover and days of supply to optimize cash flow. This data helps you balance inventory investment with customer service levels.

- Best Practice: Monitor inventory turnover by product category to identify optimization opportunities. Set target ranges based on industry benchmarks and your service requirements.

- Measure Customer Lifetime Value (CLV): CLV analysis helps you optimize the relationship between service investments and long-term profit. Understanding which customer segments have the highest CLV allows you to target your service-level investments for maximum return.

Implementing Advanced Strategies for Growth and Efficiency

- Drive Down Costs: Systematic cost reduction requires ongoing work. You must use your volume and performance data to negotiate better carrier rates. At the same time, pursue packaging optimization to reduce dimensional weight and material costs.

- Develop a Multi-Warehouse Strategy: A multi-warehouse network reduces shipping times and costs by placing inventory closer to your customers. This strategy increases complexity, but for scaling brands, it is a powerful competitive tool.

- Key Metric: A well-executed multi-warehouse network can reduce average shipping costs by 15-25% while improving delivery times by 1-2 days.

- Plan for Cross-Border Expansion: International expansion creates huge growth opportunities but adds significant operational complexity. You must master landed cost calculations, duty optimization, and customs compliance.

- Critical Warning: International shipping regulations are complex and change constantly. You must invest in specialized expertise or partner with experienced providers to avoid costly compliance failures.

Future-Proofing Your D2C Operation

Long-term success requires balancing current operational excellence with strategic investments in future capabilities. You must build flexibility into your operations and embrace emerging technologies.

- Evaluate AI and Machine Learning: AI and machine learning enable more sophisticated demand sensing and operational optimization. These technologies can identify patterns that traditional analytics miss, giving you a competitive advantage through better predictions.

- Key Metric: Organizations using AI for demand forecasting typically achieve a 10-20% improvement in forecast accuracy, leading to lower inventory costs and fewer stockouts.

- Assess Micro-Fulfillment and Automation: Micro-fulfillment centers (MFCs) and warehouse automation are powerful tools for increasing delivery speed and reducing labor costs. As these technologies mature, they will become critical for competing in dense urban markets.

- Definition: Micro-fulfillment centers are small, automated warehouses located close to customers, enabling same-day or next-day delivery at competitive costs.

- Build a Sustainable Supply Chain: Sustainability increasingly influences purchasing decisions. Proactive strategies like using eco-friendly packaging and offering carbon-neutral shipping can create a competitive advantage and mitigate long-term risk.

Conclusion

Building a scalable D2C supply chain is a strategic imperative that directly reinforces your brand promise. Success hinges on selecting the right partners and technologies to create a resilient, visible, and profitable operation. This four-phase framework provides the systematic approach needed to build capabilities that support sustainable growth. Your work is to transform your supply chain from a cost center into your sharpest competitive weapon.

Frequently Asked Questions

1. When should I switch from in-house fulfillment to a 3PL?

The transition point is typically between $2-5 million in annual revenue or 500-1,000 orders per day. A 3PL offers scalability and expertise, while in-house provides maximum control. The decision must be based on a total cost of ownership analysis that includes labor, technology, and facility costs.

2. How do I manage complex international shipping and customs?

You must partner with experienced international logistics providers who handle customs, duties, and compliance. Implement a landed cost calculator at checkout for transparency and use global trade management systems to automate processes and optimize duty payments for a seamless customer experience.

3. What is the difference between an OMS and a WMS?

An Order Management System (OMS) is the brain, managing orders across all channels and routing them for fulfillment. A Warehouse Management System (WMS) is the muscle, optimizing the physical tasks within the warehouse like picking and packing. Scaling brands need both integrated systems for end-to-end automation.

4. How does a good returns strategy increase customer loyalty?

A strategic reverse logistics program turns a negative experience into a positive one. By offering a simple, fast, and communicative returns process, you demonstrate a commitment to customer satisfaction. This builds trust and often strengthens the customer relationship more than a perfect initial sale.

5. What are the first steps to implement warehouse automation?

Start by standardizing your processes and implementing a robust WMS to gather baseline performance data. Begin with simple, high-impact automation like conveyor systems for repetitive tasks. A typical ROI timeline is 12-18 months for basic systems, making it an accessible strategy for scaling brands.