Choosing the right material for your eyewear collection feels like a purely technical decision, but it’s one of the most strategic choices you’ll make. It’s easy to get lost in spec sheets comparing strength and weight, but the real challenge is connecting those properties to what truly matters: your brand’s reputation, your manufacturing timeline, and your long-term profitability. This guide provides a different approach, moving beyond simple pros and cons to a strategic framework for making a choice that is not just technically sound, but financially smart.

The best eyeglass frame material depends on your priority. For durability and performance, titanium and nylon blends like TR-90 are top choices. For rich, unique colors and a premium feel, cellulose acetate is the standard. For hypoallergenic needs, titanium, stainless steel, and acetate are excellent. Your final choice involves balancing design goals, manufacturing realities, and budget.

Eyeglass Frame Materials: A Comparative Performance Matrix

A Scored Comparison of All Key Frame Materials

This matrix provides a simplified, at-a-glance comparison of the most common eyewear frame materials based on four critical performance metrics, with 1 being poor and 5 being excellent. Use this as a starting point for your material consideration before a deeper analysis.

| Material | Strength / Durability Score | Lightweight Score | Corrosion Resistance Score | Hypoallergenic Score |

| Cellulose Acetate | 3 | 3 | 4 | 5 |

| Nylon / Grilamid | 4 | 5 | 4 | 5 |

| TR-90 | 5 | 5 | 4 | 5 |

| Propionate | 3 | 4 | 4 | 5 |

| Polycarbonate | 5 | 4 | 4 | 5 |

| Optyl / SPX | 3 | 5 | 5 | 5 |

| Titanium (Pure) | 5 | 5 | 5 | 5 |

| Beta-Titanium | 5 | 5 | 5 | 5 |

| Flexon | 5 | 4 | 5 | 4 |

| Stainless Steel | 4 | 4 | 4 | 5 |

| Monel | 3 | 3 | 2 | 1 |

| Beryllium | 4 | 4 | 5 | 4 |

| Aluminum | 3 | 5 | 5 | 5 |

| Carbon Fiber | 5 | 5 | 5 | 5 |

| Wood / Horn | 2 | 4 | 1 | 5 |

| 3D-Printed (PA12) | 4 | 5 | 4 | 5 |

A Guide to Eyeglass Material Families: Plastics, Metals, & Composites

The Workhorse Plastics & Polymers: From Premium Acetate to Performance Blends

The world of plastics offers a vast spectrum of options, from the artisanal feel of acetate to the high-tech resilience of performance nylons. Your choice in this category will define your frame’s aesthetic, feel, and durability.

First is Cellulose Acetate (Zyl), a plant-based bioplastic known for its unmatched color versatility. Because color is layered into the material itself, it allows for rich, unique patterns like tortoiseshell that won’t chip or fade. This makes it the ideal choice for fashion-forward, luxury, and designer frames where aesthetic appeal is paramount. Its primary limitation is a susceptibility to heat damage and UV degradation over time.

Next are Nylon and its high-performance blends like Grilamid and TR-90. These materials are defined by extreme flexibility, high impact resistance, and a lightweight feel. This solves the need for frames that can withstand bending and twisting without breaking, making them perfect for sports, performance, and children’s eyewear. While incredibly durable, they generally offer fewer color options than acetate and can have a less premium feel.

Propionate is a nylon-based plastic that is lightweight, hypoallergenic, and can achieve a high-gloss, transparent finish. It offers a middle ground, providing a more premium look than standard nylon while being lighter than acetate. It’s a great choice for lightweight fashion frames but lacks the deep, layered color potential of acetate.

For maximum protection, Polycarbonate is the answer. Its superior impact resistance makes it the standard for safety glasses, sports goggles, and protective children’s frames. While exceptionally strong against impact, it is more rigid and less flexible than performance nylons.

Finally, proprietary materials like Optyl and SPX represent the cutting edge. These are ultra-lightweight, hypoallergenic plastics with a “shape memory” that helps them hold precise adjustments. They are used in high-end, minimalist designs to create exceptionally comfortable frames, but their exclusive nature comes with a higher cost.

The High-Tech Metals & Alloys: From Feather-Light Titanium to Cost-Effective Options

Metal frames offer a sleek, minimalist aesthetic and varying levels of technical performance, from premium aerospace alloys to cost-effective workhorses.

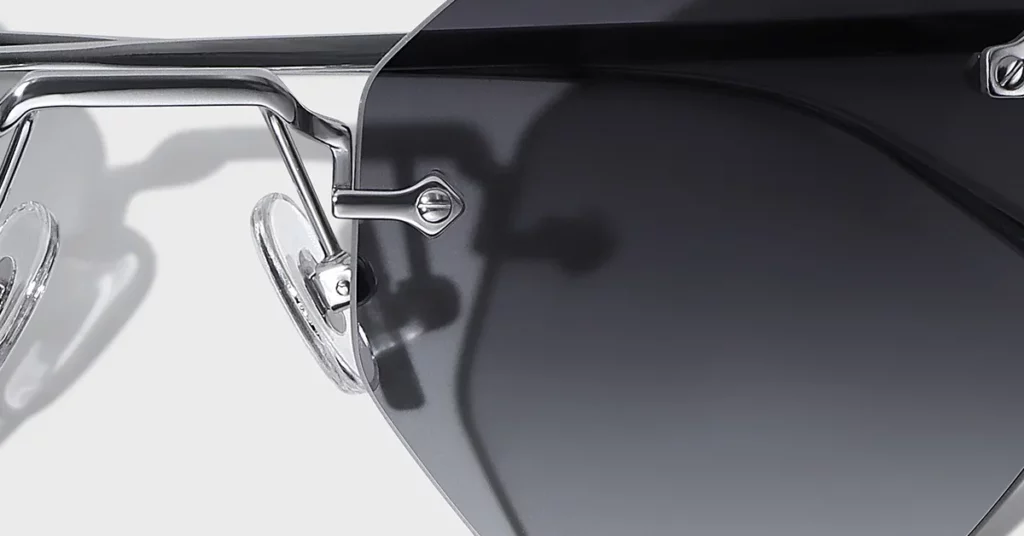

Pure Titanium is a premium material valued for its superior strength-to-weight ratio, making it ideal for minimalist, drill-mount, and high-performance frames. It is 100% hypoallergenic and completely corrosion-proof. Its primary drawback is a higher cost and more complex manufacturing process. Beta-Titanium adds a crucial element of flexibility, making it better for ultra-thin designs that need to withstand minor bending.

| Feature | Pure Titanium | Beta-Titanium |

| Flexibility | Rigid, holds its shape firmly | Highly flexible and elastic |

| Strength | Very high strength-to-weight | Higher strength and fatigue resistance |

| Best For | Robust, classic designs | Thin, minimalist designs requiring resilience |

| Cost | Premium | Higher premium due to advanced processing |

Flexon is a “memory metal” or shape-memory alloy that can be severely bent and will spring back to its original shape. This makes it perfect for children’s eyewear or anyone hard on their glasses. However, its high nickel content can be an issue for those with skin sensitivities.

Stainless Steel is a fantastic alternative, providing a high-performance option at a more accessible price point. It’s strong, lightweight, and typically hypoallergenic, solving the cost problem associated with titanium. It’s a great choice for sleek, modern designs, though it is slightly heavier than titanium.

Lower-cost alternatives include Beryllium, which offers titanium-like corrosion resistance, and Aluminum, which is extremely lightweight and allows for unique, design-forward aesthetics. The most widely used material is Monel, a nickel-copper alloy. It is cost-effective and easy to work with, making it a staple for budget-conscious, mass-market frames.

Critical Warning: Monel’s high nickel content is a primary cause of skin allergies. It requires a protective plating, and if that coating wears off, the underlying metal can cause severe skin irritation.

Advanced Composites & Natural Materials: The Cutting Edge of Design

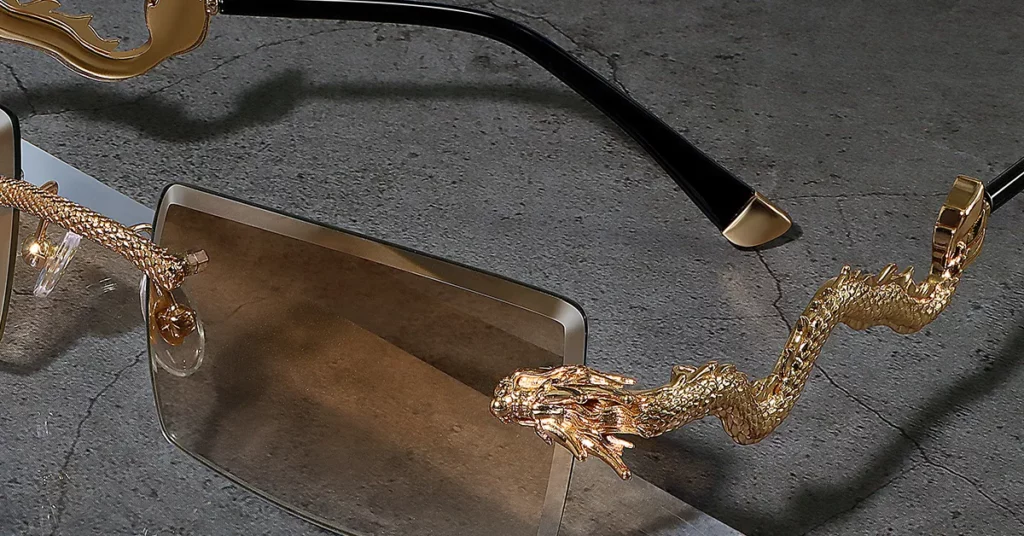

Beyond traditional plastics and metals, advanced and natural materials offer unique properties for specialized, high-end applications.

Carbon Fiber provides the highest possible strength-to-weight ratio. This ultra-lightweight and extremely rigid material is used in high-performance, luxury, and tech-focused eyewear. Its rigidity ensures perfect lens stability but also means the frames are not adjustable and can be brittle under sharp impact.

Wood, Bone, and Buffalo Horn offer a connection to natural craftsmanship. Each frame is a one-of-a-kind piece with unique grains and colors, appealing to the luxury, bespoke, and eco-conscious markets. These materials are naturally hypoallergenic but are difficult to adjust and require special care to prevent warping or cracking.

3D-Printed Materials, typically a type of nylon, are revolutionizing the industry by solving the “one-size-fits-all” problem. This technology allows for true mass personalization and custom-fit eyewear, creating complex geometries impossible with other methods. It radically accelerates prototyping, though the surface finish can feel less smooth than polished acetate.

Engineering Deep Dive: Lifecycle Performance & Common Failure Points

Weld Point Integrity: The Hidden Weakness in Metal Frames

A metal frame is only as strong as its weakest point, which is often where the temples are joined to the frame front. The integrity of this weld is a critical factor in long-term durability. Mass-produced frames often use simple spot welding or brazing, which can create brittle joints prone to breaking under stress.

Best Practice: High-quality manufacturing relies on modern laser welding. This method uses a focused beam of light to fuse the parent metals together, often with a high-strength filler wire, creating a seamless and incredibly strong molecular bond. This localized process avoids damaging nearby coatings and is a key indicator of premium construction.

| Joining Method | Laser Welding | Spot Welding / Brazing |

| Strength | Superior; fuses parent metals for a molecular bond. | Weaker; relies on filler material and is prone to breakage. |

| Precision | Pin-point accuracy with a highly localized heat zone. | Less precise; heat affects a larger area. |

| Aesthetics | Clean, nearly invisible seam. | Can be messy, leaving visible solder or discoloration. |

| Cost | Higher initial equipment cost. | Lower equipment cost but higher failure rates. |

Beyond the Spec Sheet: Understanding Material Fatigue & Stress Testing

Definition: Material fatigue is the weakening of a material caused by repeatedly applied loads. In eyewear, this is why hinges loosen or tiny cracks form near screws over months of daily use. It’s the slow, invisible failure that leads to a sudden break.

Simple Analogy: Think of bending a paperclip back and forth. It doesn’t break on the first or second bend, but each cycle adds microscopic damage. After enough cycles, the metal becomes weak and snaps unexpectedly. Material fatigue in your frames works the same way.

To measure this, the industry uses the ISO 12870 endurance test. This standard simulates real-world use by mechanically opening and closing the temples for 500 cycles. After the test, the frame is inspected for cracks, and the hinge must still function smoothly. Materials with high elasticity like beta-titanium and TR-90 excel here, while more rigid materials can fail.

The Invisible Threat: Long-Term UV Degradation in Plastic Frames

A frame’s lifecycle performance isn’t just about mechanical stress; it’s also about withstanding environmental exposure. Ultraviolet (UV) radiation from the sun and chemical corrosion from skin oils and sweat can degrade materials over time, leading to failure.

Critical Warning: Cellulose acetate is particularly vulnerable to UV degradation. Over years of sun exposure, the plasticizers can dry out, making the material brittle and prone to cracking. This can also cause a faded, chalky appearance. In contrast, performance nylons like Grilamid are formulated with excellent UV resistance, ensuring they don’t become brittle.

A Mark of Quality: The Importance of Manufacturing Tolerances

Definition: Manufacturing tolerances define the acceptable margin of error from a design’s specified dimensions. For eyewear, this means ensuring the left and right sides are symmetrical and that lenses will fit securely into the frame.

Simple Analogy: Think of building with LEGO bricks. They snap together perfectly because their manufacturing tolerance is incredibly small. If the bricks were made with loose tolerances, some would be too tight to connect and others too loose to hold, and your final creation would be wobbly and unstable.

In high-quality eyewear production, these tolerances are tightly controlled, often to within ±0.2mm for metal frames and ±0.3mm for acetate. Loose tolerances can result in wobbly lenses, asymmetrical frames, or an improper fit. Adherence to these precise standards is a hallmark of a reliable manufacturing partner.

The Kssmi Strategic Material Scorecard: From Technical Specs to Business Impact

How to Use This Scorecard: Moving From Technical Specs to Business Impact

For years, I’ve watched brands make material decisions based on simple spec sheets. But the best choice is rarely about finding the “strongest” or “lightest” option. It’s about finding the material that best aligns with your business goals. That’s why we developed the Kssmi Strategic Material Scorecard.

Simple Analogy: Think of choosing a vehicle. A spec sheet might tell you a sports car is the “fastest” and a truck has the most “towing capacity.” But that data is useless without context. The real question is: what job do you need the vehicle to do? Are you commuting in the city, hauling construction supplies, or taking your family on a road trip? The “best” vehicle depends entirely on the mission.

Our scorecard works the same way. It reframes the decision around three core business pillars: Brand Impact, Manufacturing Realities, and Lifecycle Performance. It forces you to ask the right questions to ensure the material you choose is perfectly suited for your specific mission, whether that’s launching a luxury line, a durable kids’ collection, or a fast-fashion product.

Scorecard Pillar 1: Brand & Design Impact

This pillar evaluates how a material choice affects your brand’s positioning, design possibilities, and the consumer’s perception of value. A high score means the material supports a premium, versatile, and design-forward brand story.

| Material | Brand & Design Impact Score (1-5) |

| Cellulose Acetate | 5 |

| Wood / Horn | 5 |

| Titanium / Carbon Fiber | 5 |

| Aluminum | 4 |

| Stainless Steel | 4 |

| TR-90 / Nylon | 3 |

| Polycarbonate | 2 |

| Monel | 1 |

Scorecard Pillar 2: Manufacturing & Supply Chain

This pillar assesses the practical realities of working with a material, including manufacturing complexity, scalability, lead times, and raw material costs. A high score indicates a material that is cost-effective, scalable, and has shorter, more reliable lead times.

| Material | Manufacturing & Supply Chain Score (1-5) |

| TR-90 / Nylon | 4 |

| Monel | 4 |

| Stainless Steel | 3 |

| 3D-Printed (Prototyping) | 3 |

| Cellulose Acetate | 2 |

| Titanium | 2 |

| Carbon Fiber | 1 |

| Wood / Horn | 1 |

Scorecard Pillar 3: Lifecycle & Performance

This pillar connects a material’s technical properties directly to its real-world performance and your business risk. A high score means the material has excellent long-term durability, is easy to service, and has a low warranty risk factor from breakage or allergic reactions.

| Material | Lifecycle & Performance Score (1-5) |

| Titanium / Beta-Titanium | 5 |

| TR-90 / Carbon Fiber | 5 |

| Stainless Steel | 4 |

| Nylon / Grilamid | 4 |

| Cellulose Acetate | 3 |

| Flexon | 3 |

| Wood / Horn | 2 |

| Monel | 1 |

Conclusion

Choosing an eyeglass frame material is not just a technical detail; it is a core business decision. By moving beyond simple spec sheets and using a strategic framework like the Kssmi Scorecard, you can analyze your options through the lens of brand identity, supply chain realities, and long-term financial risk. This ensures you select a material that not only looks great but also strengthens your brand and protects your bottom line. When you’re ready to align your material choice with your strategic goals, our team is here to help.

Frequently Asked Questions

1. What is the absolute strongest and most durable material for eyeglass frames?

For overall durability, combining strength, impact resistance, and flexibility, materials like TR-90 (a type of nylon) and Flexon (a memory metal) are top contenders. Titanium is also exceptionally strong and long-lasting.

2. I have sensitive skin. What are the best guaranteed hypoallergenic frame materials?

The safest choices are pure titanium, high-grade stainless steel, and plant-based plastics like cellulose acetate. These materials are nickel-free and are excellent for wearers with metal allergies or sensitive skin.

3. Why do my clear acetate frames sometimes turn yellow or cloudy?

This is typically caused by a combination of two factors: UV degradation from sunlight, which can break down the plastic over time, and absorption of skin oils and cosmetics. High-quality acetate has better stabilizers to resist this.

4. Is there a “memory metal” that can be bent and return to its shape?

Yes, the material is called Flexon. It’s a titanium-nickel alloy that can be bent or twisted significantly and will automatically spring back to its original form, making it extremely resilient.

5. From a manufacturing perspective, what is the easiest material to work with for a new eyewear brand?

For speed and scalability, injection-molded materials like TR-90 or propionate are very efficient once the initial steel mold is created. For design flexibility without massive tooling costs, cellulose acetate is a great starting point, as it is CNC-milled.