How to Vet Chinese Sunglasses Manufacturers A 10-Point B2B Checklist

To properly vet Chinese sunglasses manufacturers, you must execute a four-phase strategy. First, conduct foundational due diligence to separate true factories from trading companies. Second, validate technical capabilities through multi-unit sample orders. Third, demand and independently verify regulatory compliance for FDA and CE standards. Finally, structure a risk-averse bilingual commercial agreement that defines all quality, payment, and intellectual property terms.

The Strategic Imperative: Why China Dominates Eyewear Manufacturing

China’s command of the global eyewear market is not accidental; it is the result of four decades of specialization. The country’s eyewear exports hit $5.37 billion in 2017, proving the sector’s stability. This dominance presents a clear business opportunity, but only for brands that approach sourcing with strategic discipline rather than a focus on the lowest possible price.

Cost-Effectiveness and Unit Economics

Lower labor costs in China are a known advantage, but the real value is in total cost efficiency. Access to domestically produced raw materials like acetate and metals reduces input costs by 15-25%. This means you can achieve superior unit economics that fund growth and marketing, a direct financial outcome of sourcing from a mature ecosystem.

Critical Warning: The lowest price quoted is rarely the best value. You must calculate the total landed cost, which includes quality control inspections, compliance verification, shipping, duties, and potential remediation expenses for defective units.

The Advantage of Mature Supply Chains

China’s eyewear supply chain is a dense, integrated ecosystem. Frame manufacturers, lens suppliers, and hardware producers are geographically concentrated, which allows for reduced lead times and tighter quality control. This proximity means you can execute rapid prototyping and design modifications, allowing your brand to react swiftly to market trends.

High-Capacity Production for Scalability

Leading Chinese facilities produce over 60 million pairs annually, offering immense scalability. This high capacity is powered by advanced automation in injection molding and CNC machining. This means you receive reproducible quality across high-volume runs, which directly translates to brand consistency and customer trust as you grow.

Understanding China’s Primary Eyewear Manufacturing Hubs

Your choice of manufacturing region directly impacts your product’s quality, cost, and brand positioning. You must select a hub whose specialization aligns with your business strategy.

| Region | Primary Focus | Strengths | Ideal For |

| Shenzhen & Dongguan | High-End / Premium | Advanced electroplating, precision manufacturing, luxury-grade finishes. | Premium and luxury brands requiring superior consistency. |

| Wenzhou & Taizhou | Mid-to-High Volume | Balanced cost and quality, strong in both metal (Wenzhou) and plastic (Taizhou). | Brands needing flexibility and competitive mass-market pricing. |

| Xiamen | High-Volume Sunglasses | Deep heritage in sunglasses production, supplying over 50% of the global market. | High-volume orders focused on established sunglasses designs. |

Pro Tips: Shenzhen’s proximity to Hong Kong’s logistics infrastructure is a key operational advantage. Wenzhou, with over 500 eyewear enterprises, offers a competitive landscape perfect for negotiating terms. Xiamen’s specialization means they are exceptionally efficient at producing sunglasses at scale.

Phase 1: Foundational Due Diligence

Advanced Sourcing Strategies

Vetting on B2B Platforms

Standard B2B platforms like Alibaba are merely starting points. Your first filter must be to identify genuine factories versus trading companies. Prioritize suppliers with Gold Supplier status, Trade Assurance, and multiple years of platform history. Demand detailed company profiles that list production equipment, facility size, and employee counts because a real manufacturer knows these details; a trading company will be vague.

Using Professional Sourcing Agents

A professional sourcing agent provides access to high-quality factories not listed on public platforms. Select agents with specific eyewear industry experience. Their value is in navigating communication and providing on-the-ground quality assessment, which mitigates significant sourcing risk.

Maximizing Trade Show ROI

Attending the Hong Kong International Optical Fair for premium goods or the Wenzhou International Optics Fair for specialized eyewear provides direct access. It allows you to assess product quality and engage with manufacturers face-to-face, accelerating your vetting process.

Critical Initial Screening and Verification

Manufacturer vs. Trading Company

You must analyze the company’s official business scope on their registration documents. A manufacturer’s license will list production and facility operation. A trading company’s license will only authorize import/export activities. Demand a live video tour of the production floor; a refusal is a major red flag.

Verifying Supplier Legitimacy

Use the National Enterprise Credit Information Publicity System (NECIPS) in China to cross-reference the company’s name and registration number. This is a non-negotiable step to confirm authenticity. Further verify their activity by checking export records on platforms like ImportGenius, which shows real shipping history and protects you from fraudulent actors.

Evaluating Professionalism and Communication

A professional manufacturer provides a detailed quotation that specifies material grades, production processes, and timelines. Their technical knowledge becomes apparent when they offer proactive suggestions for design optimization. This demonstrates manufacturing depth, which directly translates to a more reliable partnership.

Reviewing Key Certifications

- ISO 9001: This certificate indicates a mature quality management system. You must verify the certificate’s authenticity with the issuing body, as this proves they have systematic production controls.

- BSCI / SEDEX: These audits verify social compliance, including worker rights and safety. This is not about ethics alone; it is about mitigating the brand and legal risks associated with non-compliant supply chains.

For Example: A supplier holding a current ISO 9001, a BSCI Grade A rating, and a consistent three-year export history presents a low-risk profile for a long-term partnership.

Phase 2: Technical & Quality Assurance Vetting

Aligning Manufacturing Model with Your Strategy

| Model | Description | Best For | Key Outcome |

| OEM (Original Equipment Mfg.) | You provide the 100% custom design. The factory builds it exclusively for you. | Brands with proprietary designs and a focus on differentiation. | Protects your intellectual property and secures brand exclusivity. |

| ODM (Original Design Mfg.) | You select and modify a pre-existing design from the factory’s catalog. | Brands prioritizing speed-to-market and lower initial tooling costs. | Reduces development time and cost, accelerating market entry. |

Deconstructing the Product: Materials and Components

Frame Material Analysis

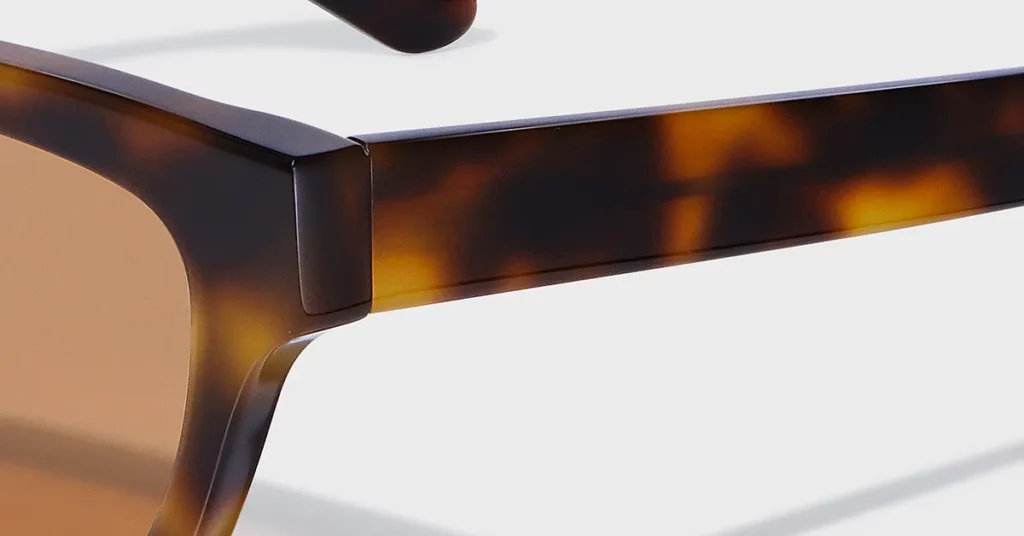

Your material choice is a strategic decision that defines your brand’s position in the market.

| Frame Material | Cost | Durability | Weight | Brand Positioning |

| Acetate | Medium | High | Medium | Premium / Fashion |

| TR90 | Low-Medium | Very High | Very Light | Sport / Active |

| Polycarbonate | Low | Medium | Light | Mass Market |

| Stainless Steel | Medium | High | Medium | Contemporary |

| Titanium | High | Very High | Very Light | Luxury / Premium |

Lens Technology Evaluation

- UV400 Protection: This is the absolute minimum standard. The rule is to independently test for UV protection because failure here creates a massive liability risk for your brand.

- Polarization: High-quality polarized lenses achieve 99% glare reduction. You must demand polarization efficiency test reports to validate performance claims, as this is a key feature that justifies a higher retail price.

- Premium Lenses: Sourcing from suppliers like Carl Zeiss increases unit cost but provides a powerful competitive differentiator, which supports higher margins and builds brand equity.

Component Quality Assessment

Component quality is a critical, often overlooked, detail. In my two decades on factory floors, I’ve consistently observed that hinge failure is a top driver of warranty claims. You must prioritize hinge quality as an indicator of overall manufacturing standards.

Key Metric: A premium hinge must withstand 25,000+ open/close cycles without tension loss. Demand durability testing data for all hardware.

Rigorous Quality Control and Production Oversight

The Importance of a Detailed Tech Pack

A comprehensive tech pack is your primary tool for eliminating miscommunication. It is a technical blueprint that must include material specifications, dimensional tolerances, color standards, and quality acceptance criteria. This document ensures design fidelity, which reduces production errors and protects your investment.

Multi-Unit Sample Orders

A single sample is a marketing tool; a 10-50 piece sample order is a diagnostic tool. Ordering a larger batch reveals production consistency across different material lots and operator shifts. This is the only way to judge the factory’s true production quality, not just their ability to make one perfect sample.

On-Site or Third-Party Factory Audits

An audit verifies that the factory’s claimed capabilities are real. The objective is to evaluate equipment condition, worker training, and quality control procedures.

Critical Warning: Reluctance to grant full facility access, incomplete quality documentation, or evidence of undisclosed subcontracting are all grounds for immediate disqualification.

Establishing an AQL Standard

An Acceptable Quality Limit (AQL) provides an objective, contractual standard for final product inspections. It defines the maximum number of acceptable defects before a shipment is rejected. Implementing an AQL based on ISO 2859 is a fundamental risk management practice that protects your brand’s reputation.

Phase 3: Regulatory & Compliance Verification

Navigating United States FDA and Safety Regulations

FDA Class 1 Medical Device Status

The FDA classifies sunglasses as Class 1 medical devices. This is a critical rule because it mandates annual establishment registration for both the foreign manufacturer and your business as the importer. Failure to maintain a current registration, which costs $5,000-$6,000 annually, will result in shipment detention at the border.

The Mandatory Drop Ball Test

Per regulation 21 CFR 801.410, every single shipment must be accompanied by a drop ball test certification. This test confirms the impact resistance of the lenses.

Definition: A fracture is defined as the lens breaking through its entire thickness into two or more separate pieces. Insufficient documentation for this test is a common reason for customs delays and shipment rejection, disrupting your entire supply chain.

California Proposition 65

This regulation restricts over 800 chemicals. This is a major compliance risk because many eyewear materials can contain restricted substances like lead or cadmium. You must demand chemical testing reports specific to Proposition 65 because non-compliance can lead to severe fines and a loss of access to the California market.

Meeting European Union Standards

CE Marking for PPE

For the EU market, sunglasses require a CE marking under the Personal Protective Equipment (PPE) Regulation 2016/425. This marking is a declaration that your product meets essential health and safety requirements. This self-declaration process means the legal responsibility for compliance rests entirely on you, the importer.

EU Technical File and EN ISO 12312-1

You must assemble and maintain a technical file for ten years. This file must contain test reports proving compliance with the harmonized standard, EN ISO 12312-1:2022. This standard sets the performance requirements for UV protection and optical quality. Failure to produce this file upon request can result in a market recall.

REACH Regulations

The REACH regulation restricts chemical substances in all products sold in the EU. You must ensure your products are tested for compliance, particularly regarding nickel in metal frames. This protects you from legal action and ensures market access.

The Importer’s Burden: Proactive Verification

Best Practice: Assume every new supplier is non-compliant by default. You must proactively request and independently verify all test reports and certifications. Contact the issuing laboratory directly to confirm the authenticity of any document provided. Relying on manufacturer claims without verification exposes your business to unacceptable financial and legal risk.

The Financial Impact of Non-Compliance

Compliance failures lead to customs seizures, FDA detention, and massive fines. Furthermore, Section 301 tariffs on Chinese products can dramatically increase your costs.

Key Metric: Combined duties on some Chinese plastic eyeglass frames can now reach approximately 155%, including base duties and tariffs. Factoring this into your cost analysis is essential for survival.

Phase 4: Commercial & Legal Finalization

Defining Production and Financial Terms

Analyzing Minimum Order Quantities (MOQs)

MOQs are not arbitrary; they reflect the factory’s operational model. Suppliers in Yiwu may offer MOQs of 600-1,000 pieces. In contrast, a high-end Shenzhen manufacturer delivering superior quality will demand 2,000-5,000 pieces. You must align your order volume with a factory whose business model matches your own.

Calculating Total Landed Cost

You must calculate costs beyond the factory gate. Custom tooling can range from $2,000-$15,000. Custom packaging adds $0.50-$2.00 per unit. Air freight can cost $3.00-$8.00 per unit, compared to ocean freight at $0.50-$1.50. Ignoring these costs will destroy your profit margins.

Establishing Secure Payment Terms

A Letter of Credit (L/C) is the most secure payment method. It makes payment contingent on the supplier meeting all documented requirements, including quality inspection reports. This protects your capital while assuring the manufacturer of payment upon successful completion.

Critical Warning: Never send payment to a personal bank account or use a Western Union transfer. These methods bypass standard banking documentation and eliminate your recourse in a dispute. This is a common tactic used by fraudulent operators.

Building a Legally Sound Supplier Agreement

The Need for a Bilingual Contract

Your contract must be bilingual in both English and Chinese. The assertion that an English-only contract is sufficient is a dangerous misconception. A bilingual contract prevents misinterpretation and is enforceable in Chinese courts, which provides you with actual legal protection.

Defining All Critical Terms

Your agreement must be a detailed operational playbook. It should specify product requirements, material grades, AQL standards, and clear protocols for handling defects. This level of detail removes ambiguity and gives you contractual grounds to reject non-conforming products.

Defining Intellectual Property Ownership

Your contract must explicitly state that you own all rights to any custom molds and exclusive designs. This provision is your primary defense against your supplier selling your proprietary designs to competitors, which is a common and financially damaging occurrence.

Beyond the Checklist: Cultivating Long-Term Success

Building a Resilient Supplier Relationship

The goal is to evolve the relationship from a simple transaction to a strategic partnership. This is achieved through clear, consistent communication and shared goals. Provide your manufacturing partner with market feedback and growth projections. This allows them to invest in capacity and capabilities that support your future needs, creating a powerful competitive advantage for your brand.

Leveraging Your Partner for Innovation

Once a foundation of trust is built, you can collaborate on innovation.

- Sustainable Materials: Discuss using reclaimed plastics or plant-based polymers. These materials support a premium sustainability position, which can justify higher price points and attract environmentally conscious consumers.

- Health-Focused Technology: Explore enhanced blue light blocking or advanced photochromic lenses. These technologies address growing consumer health concerns and create tangible product differentiation.

- Smart Features: For brands at the cutting edge, Shenzhen manufacturers offer advanced capabilities for integrating features like voice assistants and touch controls, opening up new product categories.

Conclusion

Selecting a wholesale sunglasses china suppliers or Chinese sunglasses manufacturer is a strategic process that hinges on systematic risk mitigation. This framework provides the tools for rigorous technical, regulatory, and commercial due diligence. Success demands disciplined preparation and continuous oversight. You must transform your sourcing process from a search for a supplier into the development of a strategic partner to build a resilient supply chain and secure a competitive advantage in the global market.

Frequently Asked Questions

1. What is the most common mistake buyers make?

The most critical error is failing to distinguish between genuine manufacturers and trading companies. Buyers focus on price without verifying manufacturing capabilities, which leads to quality failures and limited recourse. Always demand facility tours and business scope verification.

2. How do I verify if a supplier’s ISO 9001 certificate is authentic?

You must verify the certificate through the issuing body’s official online database using the certificate number. Contact the certification body directly to confirm its validity and scope. Never accept a certificate without verifiable issuing body contact information.

3. What are the risks if a factory has no prior export experience?

The primary risks are an inadequate understanding of market-specific regulations like FDA registration, improper documentation, and potential customs seizures. This exposes your business to significant liability. Mitigate this by requiring third-party verification of all compliance protocols before placing large orders.

4. What is a realistic FOB cost difference between basic and premium sunglasses?

A basic, non-polarized polycarbonate frame sunglass typically costs $2-$5 FOB. In contrast, a high-quality acetate frame with premium polarized lenses will range from $12-$25 FOB. The difference reflects superior materials, advanced lens technology, and higher manufacturing standards.

5. What other tests should be considered for a luxury eyewear line?

For a luxury line, you must demand UV transmission testing (ISO 12312-1), nickel release testing for metal frames (EN 16128), salt spray corrosion testing, and extensive mechanical durability tests, including hinge cycle testing, to substantiate premium quality claims.