The Kssmi Quality Control Protocol: How We Ensure Handmade Quality at Any Volume

Premium eyewear manufacturing requires a multi-stage quality control protocol that includes Incoming Quality Control (IQC) for raw materials, In-Process Quality Control (IPQC) during manufacturing, and Final Quality Control (FQC) before shipment. This system ensures consistent handmade quality by establishing verifiable benchmarks, implementing statistical controls, and maintaining complete traceability, which directly protects your brand and profitability.

The Business Case for a Rigorous QC Protocol

A disciplined QC protocol delivers measurable return by preventing defects, protecting your brand, and creating a market differentiator. The cost of implementing QC is typically 2-5% of total production costs, whereas the cost of quality failures can exceed 15-20% of revenue through returns, recalls, and brand damage.

Mitigating Financial Risk

Quality failures discovered at the shipment stage create cascading financial damage. A single defective shipment of 10,000 units can generate costs exceeding $150,000 when you factor in product replacement, logistics, and opportunity costs.

Pro Tips: Implement statistical sampling using AQL (Acceptable Quality Limit) standards. Classifying defects into Critical, Major, and Minor categories allows for data-driven quality decisions that protect your investment while maintaining cost efficiency.

Protecting Brand Integrity

Consumer research shows that 70% of premium eyewear buyers see consistency as a primary quality indicator. Brand reputation damage from quality issues can reduce market value by 10-15% in a single product cycle, making QC investment essential for long-term survival.

Creating a Competitive Advantage

Brands with verifiable QC protocols gain a significant advantage in B2B negotiations. The ability to provide detailed quality documentation, traceability records, and performance guarantees enables you to command premium pricing and secure stronger supplier relationships.

Defining the “Handmade Standard” as a Verifiable Benchmark

The “handmade standard” is not a production method; it’s a measurable quality threshold that separates premium eyewear from mass-produced goods. This standard is defined by quantifiable parameters for surface finish, component tolerances, and ergonomic performance that can be replicated at volume.

The Golden Sample serves as the contractual reference for all production units. This prototype’s dimensions, color specifications (using Pantone), and performance criteria are exhaustively documented. It must be stored under controlled conditions (24°C at 50% humidity) to prevent material changes.

Critical Warning: Factory personnel have been known to deliberately alter or misplace approved samples to obstruct third-party inspections. You must establish secure sample storage protocols and maintain duplicate reference sets to prevent production deviations that can compromise entire shipments.

The Three-Pillar Framework for Vetting Manufacturer Quality

Pillar 1: Foundational Integrity via Incoming Quality Control (IQC)

IQC is your first line of defense. Verifying all raw materials before they enter production prevents downstream quality issues that become exponentially more expensive to fix.

Raw Acetate Verification

Acetate sheets require a 7-day curing period at 60°C to achieve dimensional stability. This process prevents post-production warping. Your supplier must provide batch certificates indicating curing conditions. Acetate stored for less than 12 months shows optimal stability.

Technical Inspection of Metal Components

Metal components must undergo rigorous mechanical and chemical testing. This includes hinge cycle testing for 25,000 operations, plating adhesion testing using the cross-hatch method (ASTM D3359), and corrosion resistance testing with artificial sweat (ISO 3160-2). These tests ensure long-term durability and prevent field failures.

Lens Qualification

Lens qualification validates optical performance and safety. This involves optical power verification with a focimeter, UV transmission testing to confirm 100% UV400 protection, and impact resistance testing using the drop ball method (ANSI Z80.3). Passing the drop ball test is non-negotiable for consumer safety.

Establishing the Acceptable Quality Limit (AQL)

AQL provides a statistical framework for accepting or rejecting incoming material batches. For premium eyewear, you must demand adherence to strict AQL levels.

| Defect Class | Maximum Acceptable Rate | Business Impact of Failure |

| Critical | 0.15% | Poses a safety risk; leads to recalls and liability. |

| Major | 1.5% | Affects function or usability; results in high return rates. |

| Minor | 4.0% | Cosmetic imperfection; erodes premium brand perception. |

Pillar 2: Process Discipline via In-Process Quality Control (IPQC)

IPQC monitors production in real-time, allowing for immediate corrections before small errors become batch-level disasters. This proactive control is the key to scalable quality.

CNC & Shaping Accuracy

CNC machining requires constant verification against CAD files with tolerances of ±0.1mm for functional surfaces.

Key Metric: A first-article inspection of the initial 20 units establishes baseline accuracy. Following this, you must sample every 100th unit to monitor for any process drift that could compromise the entire batch.

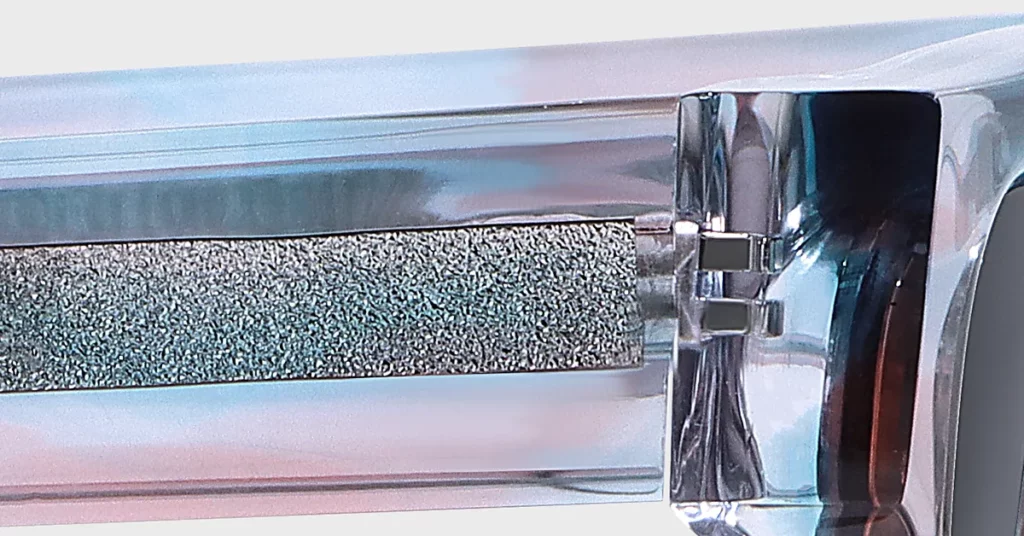

Polishing & Finishing Excellence

The multi-stage tumbling process that creates a mirror-like lustre requires precise timing and media control. Tumbling media degrades over time; it must be replaced every 500 processing hours to maintain a consistent finish. A gloss meter reading between 85-95 GU (Gloss Units) is the target for premium acetate.

Lamination & Curing Integrity

Acetate lamination demands ultrasonic inspection to detect internal defects like air bubbles or delamination.

For Example: A 10MHz ultrasonic transducer can find air bubbles as small as 0.5mm. This technology prevents structural failures that are invisible to the naked eye but can cause a frame to break under normal stress.

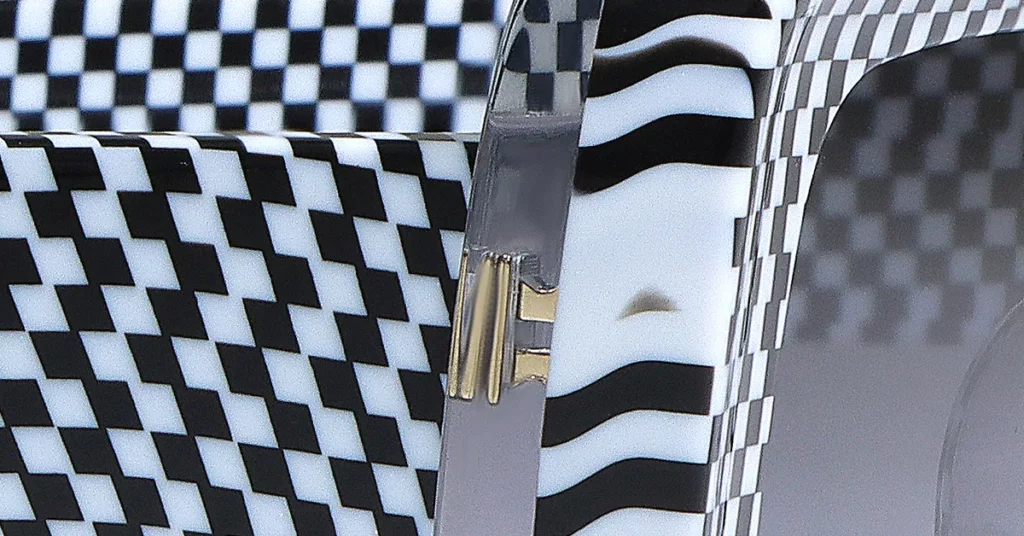

Component & Assembly Precision

Assembly must use precision jigs to ensure consistent component placement. Go/no-go gauges verify hinge insertion depth, while specialized fixtures confirm core wire placement is aligned within ±0.1mm. This precision prevents uneven stress distribution and ensures a comfortable, durable final product.

Pillar 3: Final Assurance via Pre-Shipment Inspection (FQC/PSI)

The pre-shipment inspection is your final opportunity to verify that products meet every specification before they reach your customers. This audit prevents field failures and protects your brand from negative reviews.

Full Assembly Functional Testing

Every finished unit must undergo functional testing. This includes a 50-cycle hinge operation test to confirm smoothness, temple fold checks to ensure proper fit, and lens security tests using specified force applications. Hinge torque should measure between 0.5-1.2 Nm for a premium feel.

Aesthetic & Cosmetic Audit

Cosmetic inspection must occur under standardized 6500K daylight illumination at 1000 lux. Inspectors use magnification to identify any scratches over 0.5mm, tool marks, or polishing burns.

The Bottom Line: Cosmetic flaws account for 60% of customer complaints in premium eyewear. A rigorous aesthetic audit is not optional; it is a core business requirement.

Final Regulatory & Standards Verification

Final inspection confirms all markings and certifications adhere to international standards like ISO 12870 (spectacle frames) and EN ISO 12312-1 (sunglasses). This step is critical for avoiding customs delays and legal issues in your target markets.

Beyond the Production Line: Auditing Your Partner’s Culture

A factory’s true commitment to quality is revealed in its systems and its people, not just its inspection reports. You must evaluate the underlying culture to ensure a successful long-term partnership.

Assessing the Quality Management System (QMS)

ISO 9001:2015 certification is the baseline proof of a standardized QMS. It demonstrates documented processes for everything from management responsibility to continuous improvement.

Definition: ISO 9001:2015 is the international standard for quality management, emphasizing the risk-based thinking necessary to produce consistently high-quality eyewear.

End-to-End Traceability

Demand a system that provides batch and lot tracking from raw material to shipped unit. This traceability enables rapid containment of any quality issues, supports root cause analysis, and is a non-negotiable part of modern manufacturing.

The Human Element

The skill and empowerment of the workforce are your ultimate quality guarantees. Expert craftsmanship must be documented in Standard Operating Procedures (SOPs) and transferred to the production team through structured training programs.

Best Practice: Empower the front line with a “Right to Stop” culture. Any worker must be able to halt production to flag a deviation without fear of reprisal. This prevents small mistakes from turning into costly recalls.

Conclusion

A multi-stage, integrated quality control protocol is the only way to scale handmade quality. This operational discipline protects your brand integrity, justifies your premium pricing, and creates a powerful competitive advantage. Demand this level of rigor from your manufacturing partner to turn quality from an expense into a strategic asset.

Frequently Asked Questions

1. How can I tell a good QC protocol from a basic one?

A strong partner shows multi-stage inspection data (IQC, IPQC, FQC), provides traceability records, and uses statistical controls. A weak one only performs a cosmetic final check and lacks deep process documentation.

2. What AQL defect rate is the benchmark for premium eyewear?

The standard for excellence is AQL 0.15% for critical defects, 1.5% for major defects, and 4.0% for minor defects. Never accept higher rates for premium production.

3. How does QC handle mixed-material frames (acetate/metal)?

It requires specialized tests for material compatibility, including checks for adhesion at the acetate-metal interface, corrosion resistance, and thermal cycling to simulate real-world stress and prevent separation.

4. What are the most overlooked QC checkpoints?

The most critical and often missed checks are acetate curing verification, ultrasonic inspection for internal bubbles, statistical process control (SPC) implementation, and end-to-end material traceability.

5. How does the acetate supplier choice affect QC needs?

Premium suppliers like Mazzucchelli provide stable material, so QC focuses on processing. Lower-grade acetate has inherent flaws like color variation and internal stress, demanding far more intensive incoming inspection.