Investing in your first production run of acetate eyewear is a major step. But what happens if hidden defects render that inventory worthless? This fear of financial loss and brand damage from flaws you didn’t know how to identify is a common hurdle for new founders. This guide provides more than a simple checklist; it offers a strategic framework for turning technical knowledge into your brand’s best defense.

The most common defects in acetate frames are structural issues like crookedness, surface flaws like poor polishing, and material failures like shrinkage. Spotting them requires a systematic visual inspection focusing on frame balance, surface reflection, and hinge function. A robust quality control process is essential to protect your investment and brand reputation.

Why Quality Control is a Brand’s First Line of Defense (The “Why”)

Understanding the Real Cost of Poor Quality (COPQ)

Definition: The Cost of Poor Quality (COPQ) represents all the expenses that would disappear if your quality were perfect. For many brands, these hidden costs can drain 15-20% of sales revenue, covering everything from prevention and inspection to the internal and external failures that eat into your profit margins.

Simple Analogy: Think of COPQ as an iceberg. The cost of the single defective unit is the small, visible tip. The enormous, hidden mass below the surface is the true cost—all the money spent on rework, scrap, shipping for returns, and warranty claims, which can sink an otherwise healthy business.

These costs are not minor operational line items but a significant financial drain. Consider a $50,000 production run of 1,000 frames. If a systemic defect like material warping affects 20% of the batch, you face an immediate $10,000 loss on unsellable inventory. This doesn’t even account for the cascading costs of inspection, logistics, and potential damage to your brand if those units reach customers.

Most Importantly: You should view Quality Control as insurance, not an expense. Your inventory is your primary financial asset. A structured QC program, including professional third-party inspections, is a small investment that acts as an insurance policy, protecting your main asset from being devalued by preventable manufacturing flaws.

Protecting Your Most Valuable Asset: Brand Reputation

The physical quality of your product is the tangible representation of your brand’s promise. When a product arrives with defects, that promise is broken, directly eroding customer trust. This is the primary driver of long-term, and often irreversible, damage to your brand’s reputation and the foundation of your customer relationships.

In today’s market, tolerance for quality failures is incredibly low. A 2023 study found that 73% of consumers are unlikely to buy from a company again after receiving just one defective item. For a new brand, a flawed first order can be catastrophic, destroying any chance to build positive customer lifetime value (CLV).

This can create a dangerous snowball effect. A customer with a defective product is highly motivated to share that negative experience online, creating a powerful deterrent for other potential buyers. Your brand’s identity is built on the consistent delivery of a high-quality experience. A rigorous QC process is not just a manufacturing step; it’s a fundamental brand-building activity.

A Visual Field Guide: Identifying 9 Common Acetate Frame Defects (The “What”)

Category 1: Structural & Assembly Defects

This category covers flaws in the frame’s core construction and balance. These defects directly impact fit and function, making them the most critical to identify.

1. Frame Crookedness & Misalignment

This is an asymmetry causing the frame to sit unevenly. You can spot it with the “four-point touch” test: place the frames upside down on a flat table. Both temple tips and the top of the frame front should touch evenly. If one temple is raised, the frame is crooked. This is typically caused by improper heating and cooling during assembly.

- Business Impact Score: 5 (Critical)

- Supplier Conversation Starter: “Our pre-shipment inspection shows frames failing the four-point touch test, with height differences exceeding the ±0.3mm tolerance. We need to pause this shipment and diagnose the root cause in the assembly or cooling process.”

2. Incorrect Pantoscopic Angle

This refers to the vertical angle of the frame front. A correct tilt is essential for optical performance, typically around 7 to 8 degrees so the bottom of the eye rim is slightly closer to the cheek than the top. An incorrect angle can cause visual distortion and headaches.

- Business Impact Score: 4 (Major)

- Supplier Conversation Starter: “We’re measuring a variance in the pantoscopic tilt outside the acceptable ±1° tolerance. This is a critical ergonomic detail. Could we review the calibration of the jig setup for the temple attachment process?”

3. Hinge & Hardware Issues

This includes loose hinges, stripped screws, or poor alignment. Temples should move smoothly with slight, consistent resistance, not feel loose. In my two decades, I’ve seen this usually stems from low-grade hardware or an incorrect embedding process. For premium frames, look for 5- or 7-barrel hinges as a marker of durability.

- Business Impact Score: 4 (Major)

- Supplier Conversation Starter: “Our inspection of batch #XYZ is flagging loose hinges that lack smooth resistance. This impacts the premium feel and durability. Could we investigate the hardware quality and the embedding process for this batch?”

4. Hairline & Stress Cracks

These are tiny fractures near stress points like hinges or lens grooves. Use a bright light and gently flex the frame to make them visible. They are often caused by overly tight lens insertion or brittle, improperly cured acetate. This defect is a ticking time bomb that guarantees future breakage.

- Business Impact Score: 5 (Critical)

- Supplier Conversation Starter: “We have identified hairline stress cracks near the lens grooves. This is a critical structural failure. We must place this batch on hold for 100% inspection and root cause analysis of the lens insertion pressure or acetate brittleness.”

Category 2: Surface & Finishing Defects

These defects relate to the look and feel of the frame’s surface. While often cosmetic, they signal poor attention to detail and undermine a premium perception.

5. Poor Polishing (“Orange Peel”)

This is a bumpy, uneven surface that lacks a deep gloss. To spot it, hold the frame under a direct light and look for a smooth, mirror-like reflection. If the reflection is wavy, it indicates a poor polish, typically from insufficient tumbling time, which should be 72 to 100 hours for a quality finish.

- Business Impact Score: 3 (Significant)

- Supplier Conversation Starter: “Our QC is flagging an ‘orange peel’ texture on batch #ABC. This finish doesn’t meet our standard for a high-gloss surface. Can we review the tumbling times and polishing compounds being used?”

6. White Oxidation & Hazing

This is a cloudy, white film on the acetate, a form of chemical degradation. It’s most common on dark frames on areas that touch the skin, like nose pads and temple tips. It is caused by plasticizers migrating to the surface from unstable or improperly cured material.

- Business Impact Score: 3 (Significant)

- Supplier Conversation Starter: “We are seeing early signs of hazing on the temple tips of the dark-colored frames. This suggests a material stability issue. Can we verify the curing process for the acetate sheets used in this batch?”

7. Scratches, Scuffs, & Impurities

This covers surface damage or embedded particles like dust. A thorough visual inspection under bright, diffused light is all that’s needed. Pay close attention to the area where the temple folds against the frame front, a common spot for scuffs caused by poor final cleaning.

- Business Impact Score: 3 (Significant)

- Supplier Conversation Starter: “Our inspection report shows units with surface scuffs and embedded dust. This points to a potential issue with handling protocols or workstation cleanliness. Can we review the final assembly and packaging procedures?”

Category 3: Material & Curing Defects

These are fundamental flaws within the acetate itself, often indicating a serious failure in a supplier’s process control.

8. Material Shrinkage & Warping

This is a delayed structural failure where the acetate deforms weeks after production. The most obvious sign is poor lens retention—if a lens pops out easily, the frame has likely shrunk. This is caused by using “young,” improperly cured acetate that wasn’t allowed to stabilize.

- Business Impact Score: 5 (Critical)

- Supplier Conversation Starter: “We are observing lens retention failure and frame warping in samples from our recent production. This indicates a critical issue with acetate stability. We need to investigate the sourcing and curing protocols for the raw materials used.”

9. Bubbles or Voids

These are air pockets trapped within the raw acetate. They are easiest to spot in lighter-colored acetate by backlighting the frame with a strong light. While a single bubble might be cosmetic, a cluster indicates a structural weak point prone to cracking.

- Business Impact Score: 3 (Significant)

- Supplier Conversation Starter: “Our inspection has found a pattern of internal bubbles within the acetate. This raises concerns about the raw material quality. Can you share the quality report from your acetate supplier for this batch?”

The Kssmi Defect-to-Decision Framework: A Founder’s QC Toolkit (The “How”)

From Passive Observer to Active Decision-Maker

The goal of this framework is to translate the technical flaws you just learned to identify into actionable business intelligence. It bridges the gap between seeing a defect and understanding its impact, allowing you to have productive, data-driven conversations with your suppliers. It shifts the dynamic from assigning blame to collaborative problem-solving.

Simple Analogy: Think of this framework as a doctor’s diagnostic chart. A good doctor doesn’t just name a symptom; they assess its severity, understand its impact on the patient’s overall health, and prescribe a specific, clear course of action. Our framework does the same for your product’s health, turning you into the expert diagnostician for your brand.

The system works by applying three integrated components: a Visual Reference, a Business Impact Score, and a Supplier Conversation Starter. This empowers you to build your own “Golden Sample” QC checklist—a perfect, approved unit that becomes the definitive benchmark for all future production.

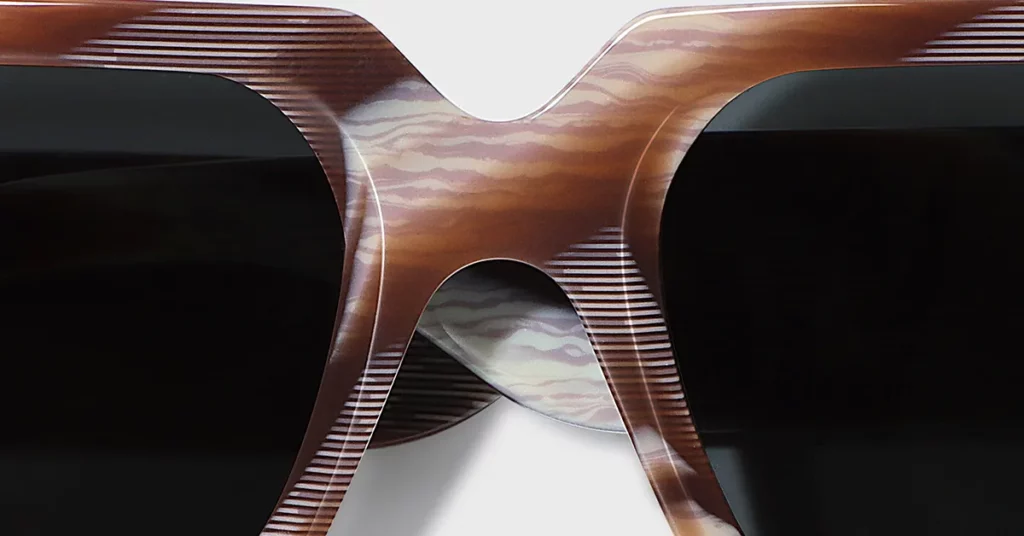

Component 1: The Visual Reference

The first step is to eliminate ambiguity. Every defect in your QC manual must be documented with high-resolution, annotated photography. Using arrows or circles to pinpoint the flaw ensures there is no room for misinterpretation, which is vital when navigating language barriers with overseas partners. A photograph is a universal language.

Best Practice: Create a shared digital folder with your supplier containing clear photos of both “Acceptable” and “Not Acceptable” examples for each potential defect. This creates clear, practical boundaries for their internal QC team to follow.

Component 2: The Business Impact Score (1-5)

This scoring system, which you saw applied to each defect above, quantifies risk. This helps you prioritize issues and define your Acceptable Quality Limit (AQL) with the factory.

- Score 1 (Minor): Negligible financial risk. A flaw a customer is highly unlikely to notice.

- Score 3 (Significant): Will cause customer complaints. A noticeable flaw that detracts from the premium feel and may drive returns.

- Score 5 (Critical): Renders the product unusable. A catastrophic failure that guarantees a return and damages brand equity.

Definition: The Acceptable Quality Limit (AQL) is a statistical method used to determine the “worst tolerable” quality level in a production batch. By assigning an impact score to each defect, you can logically set your AQL levels (e.g., AQL 0 for Critical, 2.5% for Major, 4.0% for Minor).

Component 3: The Supplier Conversation Starter

These pre-formulated scripts, provided for each defect, offer professional, non-confrontational language to address issues. They frame quality as a shared problem to solve together, which is the key to a healthy long-term manufacturing partnership.

Beyond Identification: Turning QC Knowledge into Action

Building Quality into Your Supplier Contracts

Your manufacturing agreement must move beyond vague terms like “high quality.” It needs to be a precise, legally enforceable document.

- Define Your Standards: Your contract should reference specific, internationally recognized standards. For eyewear, this means stating that all products must conform to ISO 12312-1, the global technical standard for sunglasses.

- Specify Your Protocol: The contract must detail the exact inspection method. A standard clause would state: “Final inspection will be conducted according to ISO 2859-1, using General Inspection Level II, with AQLs of 0 for Critical, 2.5% for Major, and 4.0% for Minor Defects.”

- Clarify Financial Responsibility: The contract must clearly outline the consequences of a failed inspection, including who pays for re-inspection and the remedy for a rejected batch (e.g., a full refund).

Pro Tip: Your contract should explicitly state your right to use a third-party inspection service at any time. This clause ensures you have undisputed access to verify quality with an unbiased party.

The Power of Third-Party Inspections

Using an independent inspector is non-negotiable for protecting your investment. A factory’s internal QC team can face pressure to approve borderline batches to meet shipping deadlines. A third-party inspector has no conflict of interest; their only goal is to provide an objective, data-driven assessment of your product’s quality against your standards.

Remember This: As I often say, “A $300 inspection can save you from a $30,000 inventory mistake.” The typical cost represents just 1% of a $30,000 production run—a tiny investment to prevent a catastrophic financial loss. Use them for every first production run with a new supplier, and periodically thereafter to prevent “quality fade.”

Conclusion

Quality control is not a cost; it is the ultimate protection for your investment, your brand reputation, and your peace of mind. By moving beyond simple identification and adopting a strategic approach like the Kssmi Defect-to-Decision Framework, you can transform QC from a source of fear into your greatest strength. Use this guide to build a foundation of quality that will support your brand for years to come.

Frequently Asked Questions

1. What is a reasonable defect rate to expect from a good manufacturer?

A reasonable rate is defined by the Acceptable Quality Limit (AQL) you set in your contract. For premium eyewear, a standard AQL that a good manufacturer can consistently meet is:

- Critical Defects: 0% (zero tolerance)

- Major Defects: 2.5%

- Minor Defects: 4.0%

2. How is acetate quality different between Italy and China?

The specific raw material supplier matters more than the country. High-quality producers exist in both regions. However, there are general differences between top-tier Italian acetate (like Mazzucchelli) and commodity-grade materials.

| Feature | Mazzucchelli (Italian) | High-Quality Domestic (Chinese) |

| Material Source | 100% cotton-based, plant-derived | Higher-end is cotton-based; lower-tier may use petroleum components |

| Durability | Excellent shape memory, high resistance to warping | Varies; high-end options are comparable, lower-end can be more brittle |

| Color & Depth | Renowned for deep, rich, layered colors that do not fade | Good color clarity, but may lack the same depth and UV resistance |

| Hypoallergenic | 100% hypoallergenic due to its natural cotton base | Generally hypoallergenic, but lower-tier options may cause irritation |

| Stability | Minimal shrinkage due to extensive multi-week curing | Can be prone to shrinkage if the curing process is rushed |

| Cost | Premium; considered a luxury raw material | More cost-effective, offering a good balance of quality and price |

3. Can I fix minor polishing issues myself?

Critical Warning: It is not recommended. DIY methods found online often use substances that can cause permanent, irreversible damage to acetate, causing it to turn white, warp, or become brittle. A professional optician has the proper tools and expertise to safely refinish an acetate frame without damaging it.

4. What is the single most important defect to look out for?

From a business risk perspective, the most critical defect is Hairline & Stress Cracks. While a crooked frame is more obvious, a hairline crack is a guaranteed future failure that will break during normal use, creating the worst possible customer experience and severely damaging your brand’s trust.

5. How much does a third-party inspection typically cost?

Key Metric: A standard third-party pre-shipment inspection in major manufacturing hubs typically costs between $250 and $350 USD per inspector-day. This all-inclusive fee covers the inspector’s time, travel, and the detailed photographic report, making it a minimal investment to protect your inventory.