Structuring Your Manufacturing Agreement: 7 Key Clauses for Eyewear Production

A manufacturing agreement for premium eyewear must contain seven core clauses to protect your business. These include clauses for Intellectual Property (IP), Confidentiality, Quality Control, Production & Logistics, Pricing & Payment, Liability & Warranties, and Term & Termination. Each clause must precisely define ownership, standards, and remedies to secure your supply chain, protect brand equity, and ensure profitability.

The Strategic Foundation: Aligning Contract and Business Model

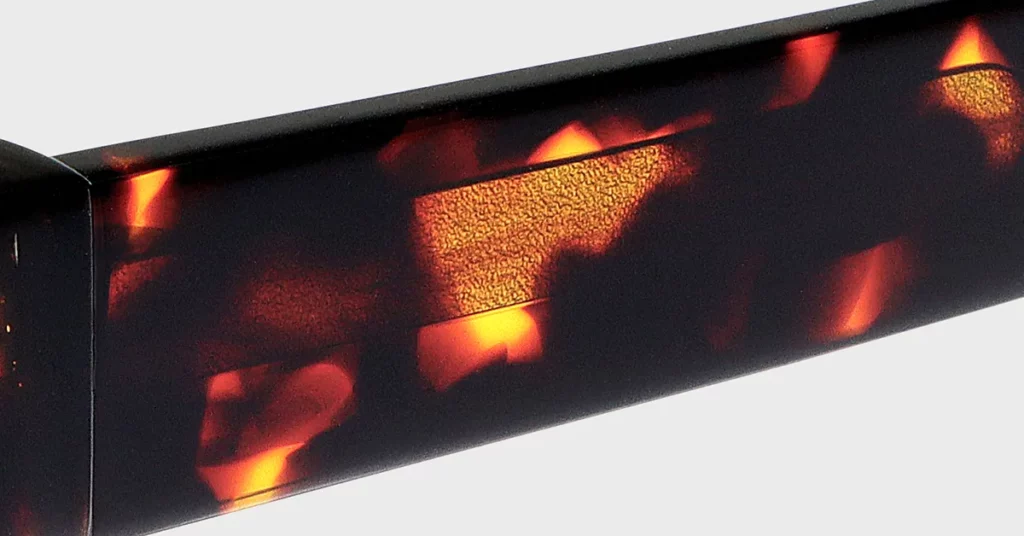

A manufacturing agreement only works when its commercial framework matches your business goals. You must begin by mapping your target margins, launch cadence, design complexity, and desired level of brand control. Differentiated acetate frames with sculpted bevels demand an OEM relationship with unambiguous tool ownership, while rapid-cycle fashion drops often thrive under a private-label structure. Your legal language must protect your specific go-to-market objectives.

Contract Manufacturing (OEM/ODM): For Brands with a Strong Design Vision

In an OEM model, you own the design DNA. You must specify that all pre-existing CAD files, brandmarks, and patentable hinge innovations remain your exclusive property. This prevents the factory from repurposing your R&D for other clients, which directly protects your competitive advantage and market position.

Key Metric: Demand a target mold cycle life of 200,000 shots. Anything less indicates inferior steel or poor maintenance, which leads to production halts and lost sales. Downtime must not exceed 2%.

Licensing Agreements: For Brands Monetizing Reputation

Licensing allows you to monetize your brand equity without taking on inventory risk. The contract must be split into two layers: a licensing schedule that stipulates minimum royalty guarantees and trademark usage, and a manufacturing addendum that enforces identical quality metrics across all licensees. This dual structure aligns financial incentives while protecting the brand’s reputation for quality.

Best Practice: Peg royalty escalators to net sales, not units shipped. This incentivizes the licensee to maintain brand value and pricing integrity, rather than liquidating stock at a discount.

Private Label vs. White Label: Differentiating Your Strategy

| Attribute | Private Label | White Label |

| Design Ownership | Brand specifies colors, trims, and packaging. | Manufacturer owns the generic design. |

| MOQ Flexibility | 1,000 units per SKU is typical. | 100–200 units per SKU is possible. |

| Branding Control | Logo on temple, box, and microfiber cloth. | Limited to a hang-tag or sticker. |

| Margin Potential | 65%–75% gross margin. | 45%–55% gross margin. |

| Risk | Low risk of commoditization; unique SKUs. | High risk of commoditization; identical products. |

Critical Warning: White-label goods often appear on global marketplaces within weeks of launch. Only choose this path if speed and low MOQs outweigh the certainty of brand dilution.

The Preamble: Setting the Stage for Absolute Clarity

Legal ambiguity creates costly disputes. Your agreement must begin with a recital stating the mutual intent: “to create, manufacture, and supply premium eyewear under the brand’s exclusive specifications for global distribution.” This anchors every subsequent clause to a single, shared mission.

Follow this with a definitions annex to eliminate any interpretive loopholes.

- Definition: Product must be defined by model code, material family (e.g., M49 acetate), and finish.

- Definition: Territory should be defined by ISO country codes.

- Definition: Intellectual Property must include molds, CAD files, brandmarks, and prototypes.

- Definition: Bill of Materials (BOM) needs to list the specific acetate origin, hinge supplier, and lens coatings.

Clauses 1 & 2: Fortifying Your Brand with IP and Confidentiality

Your eyewear’s value is locked in its design files, proprietary materials, and unique branding elements. These clauses are non-negotiable fortifications.

Clause 1: Intellectual Property (IP) Ownership and Control

State unequivocally that all pre-existing IP and all improvements developed during the contract remain your property. This is achieved through an automatic assignment clause, meaning any prototype or process refinement created during production legally vests in your brand upon its creation. This prevents a factory from claiming joint ownership of an innovation you funded.

The Tooling & Molds Protocol

Your contract must detail the purchase price, storage location, and maintenance schedule for all molds. Mandate that the factory must insure all tooling at full replacement value. You must also include a retrieval procedure: the brand may remove all tooling within seven days of contract termination, with the factory obliged to pack and ready the molds for pickup at its own cost.

The China NNN Agreement: A Non-Negotiable

A standard NDA is useless in China. You need an NNN agreement that prohibits Non-Use, Non-Circumvention, and Non-Disclosure. This prevents the factory from using your designs for other clients or selling directly to your distributors. Draft it bilingually, name a Chinese arbitration body like CIETAC, and stipulate damages in RMB to ensure it is enforceable.

Clause 2: Confidentiality and Commercial Data Security

Confidentiality must extend beyond designs to your cost sheets, sell-through data, and marketing calendars. Listing ex-works pricing and sales forecasts as confidential prevents the factory from using your own business data as leverage against you during price negotiations.

You must mandate specific data security obligations. Require written SOPs for network security, encrypted file storage, and CCTV-monitored rooms for tooling. This makes data protection a contractual requirement, not a suggestion, which reduces the risk of leaks to competitors.

Best Practice: Include a survival clause. This ensures that all confidentiality and IP obligations endure for at least five years post-termination, protecting your assets long after the relationship ends.

Clauses 3 & 4: Mandating Excellence with Production and Quality Clauses

Premium eyewear is defined by its finish and performance. You must write quality standards and logistics mechanics directly into the contract, not leave them to individual purchase orders.

Clause 3: Quality Control, Compliance, and Inspection

Your contract must attach your Quality Assurance Protocol (QAP) as a binding exhibit. The QAP is the playbook for objective testing, specifying everything from torque checks on hinge screws to pantoscopic angle verification. This transforms quality from a subjective conversation into a pass/fail test.

Defining Acceptable Quality Limits (AQLs)

You must classify defects to set clear rejection criteria. This removes emotion from the inspection process. If a batch fails, it’s rejected based on pre-agreed math, not opinion.

| Defect Class | Example | AQL Limit |

| Critical | Lens cracks, failed UV400 test | 0 |

| Major | Hinge misalignment >0.5 mm | 1.5 |

| Minor | Logo misprint <0.2 mm shift | 4.0 |

The Bottom Line: Your contract must grant your brand and its agents unrestricted rights for on-site and third-party audits with 48-hour notice. Refusal by the factory must be defined as a material breach of contract.

Clause 4: Production, Ordering, and Logistics

Reliable logistics keep your shelves stocked and marketing campaigns on track. Your agreement must codify every variable affecting lead times and landed cost. The Product Specification Annex must list approved suppliers, like Mazzucchelli for M49 acetate, and prohibit substitutions without written approval and material re-testing.

Structuring Order Mechanics

Set an annual MOQ, tiered pricing by volume, and a standard lead time (e.g., 60 days FOB). Require a rolling 180-day forecast with the first 60 days locked. This gives your factory visibility for planning while giving you flexibility.

Best Practice: Impose a late delivery penalty of 0.5% of the PO value per week, capped at 5%. This financial consequence is a powerful motivator for on-time performance.

Specifying Incoterms

Precisely define risk and cost transfer to avoid surprise charges.

| Incoterm | Seller Responsibilities | Buyer Responsibilities |

| EXW | Make goods available at their premises. | Arrange and pay for all export, freight, and import. |

| FOB | Clear goods for export, load on vessel. | Pay for ocean freight, insurance, and import duties. |

| DDP | Handle all logistics and duties, deliver to warehouse. | Unload goods at the final destination. |

Clauses 5 & 6: Securing Your Investment with Financial and Liability Clauses

Profitability depends on cost predictability and protection from downstream claims. These clauses shield your P&L.

Clause 5: Pricing, Payment Terms, and Financial Transparency

Fix base prices for 12 months. Any price reviews must be tied to a published commodity index, not a supplier’s arbitrary decision. For instance, a price may only adjust if a raw material index moves ±7% for 60 consecutive days, with the factory providing documentary proof. This protects your margins from unsubstantiated price hikes.

Defining a Milestone-Based Payment Schedule

This structure ties your cash outflow to factory performance, minimizing your financial risk.

| Milestone | % Payable | Trigger |

| Deposit | 30% | Purchase Order confirmation and material procurement. |

| Pre-Shipment | 60% | Successful pre-shipment inspection report with photos. |

| Final | 10% | Goods pass quality audit at your distribution center. |

Clause 6: Warranties, Indemnification, and Liability

Your manufacturer must guarantee products against defects in materials and workmanship for a minimum of 24 months from the date of retail sale. This forces the factory to stand behind its production quality, which reduces your costs associated with handling warranty claims.

You must also demand manufacturer’s indemnification. This clause legally and financially protects your brand from third-party claims arising from manufacturing defects or IP infringement. The supplier must cover attorney fees, settlement costs, and any recall expenses, shielding you from liability that is not your fault.

Key Metric: Require the supplier to maintain product liability insurance of US $5 million per occurrence and US $15 million aggregate. The certificate must name your brand as an “additional insured.”

Clause 7: Engineering a Clear Exit with Term, Termination, and Dispute Clauses

Every partnership ends. A clear exit path keeps inventory flowing and secures your tooling even when relationships sour.

Term, Termination, and Wind-Down Procedures

Set an initial term of three years with automatic one-year renewals unless either party gives 120-day notice. You must differentiate between termination for cause (e.g., IP breach, failed QA) and termination for convenience. A breach should trigger a 30-day cure period, after which you can terminate immediately and retrieve your tooling.

Post-Termination Obligations

Detail the wind-down process. The supplier must fulfill all final POs, return all molds and IP, delete all digital files, and provide a destruction certificate for any rejected tooling. This ensures no brand-marked overstock leaks into the gray market.

Governing Law and Dispute Resolution

Choosing the right legal framework is critical for enforcement. Adopting Hong Kong law and seating arbitration at the HKIAC provides a respected, neutral system that is familiar to Chinese parties and whose awards are enforceable globally under the New York Convention.

Best Practice: Implement a tiered dispute resolution mechanism:

- Negotiation: Senior management meeting within 14 days.

- Mediation: Formal mediation at HKIAC within 30 days.

- Arbitration: Binding arbitration if mediation fails.

Conclusion

A meticulously crafted manufacturing agreement is the blueprint for a secure, profitable, and scalable eyewear business. By engineering clauses for IP protection, measurable quality, financial transparency, and a clear exit, you convert a simple supplier into a strategic asset. This contract is the operational tool that defends your margins, protects your brand, and powers your global growth.

Frequently Asked Questions

1. What specific details should be in a Product Specification annex?

Beyond dimensions, you must add lens base curve, UV transmission class (e.g., Cat. 3), hinge torque specifications, temple flex resistance tests, plating micron thickness for metal parts, and all sustainability certifications for the raw materials.

2. What are the pros and cons of arbitration in the manufacturer’s country?

Home-country arbitration is typically cheaper and faster but carries a high risk of local bias. A neutral venue like Singapore or Hong Kong increases costs but provides perceived fairness and far greater cross-border enforceability of the final judgment.

3. How can a clause protect me if my manufacturer subcontracts work?

Your agreement must contain a clause that explicitly prohibits all subcontracting without your prior written consent. For any approved subcontractor, you must require them to be bound by the same NNN and QAP terms as the primary factory.

4. How can a Price Adjustment clause be structured fairly?

Tie price adjustments to an independent, publicly available commodity index. Set a trigger threshold (e.g., ±7% change) and a floor/ceiling. Require transparent invoices from the raw-material supplier as proof and apply the adjustment only to the affected component cost, not the entire product price.

5. What terms should govern high-cost injection mold maintenance?

The agreement must define preventive maintenance intervals (e.g., every 20,000 cycles), specify lubricant types, and set wear-limit tolerances. Require the factory to provide 90-day advance notice when a mold cavity reaches 80% of its projected life to plan for replacement.