A Guide to Sunglass Materials Sourcing Acetate vs. TR90 vs. Metal Frames from China

Choosing the right sunglass material requires a strategic analysis of its impact on your business. Acetate targets luxury markets with its handcrafted feel and deep coloration. TR90 serves performance and value segments with its lightweight flexibility. Metal alloys offer minimalist design versatility for classic to high-tech brands. The final decision directly translates to your landed cost, retail price potential, and brand story.

Strategic: Aligning Frame Material with Brand Identity

Cellulose Acetate: The Standard for Luxury and Craftsmanship

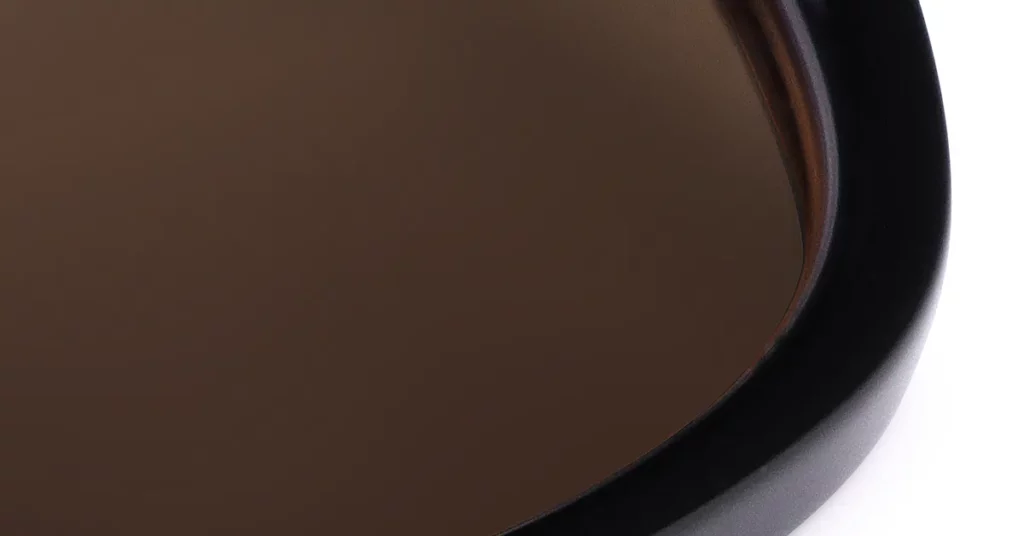

Cellulose acetate is the gold standard for premium eyewear, chosen for its aesthetic depth and high-quality tactile feel. This plant-based polymer allows for rich, layered colors and patterns, which means you can create visually distinct collections that justify a premium retail price. The material’s substantial weight communicates quality, a key purchasing factor for discerning consumers in the luxury and heritage fashion segments.

- Deconstructing the Material: Acetate is a semi-synthetic, hypoallergenic polymer derived from renewable cotton and wood pulp. Premium sheets, like those from Mazzucchelli 1849, have a controlled density and thickness (3mm-8mm). This material uniformity is not just a technical detail; it translates directly into manufacturing precision and final product reliability.

- The Aesthetic Advantage: Acetate’s primary advantage is block lamination, where different colored sheets are layered to create unique effects like tortoiseshell or marble. The color is embedded within the material, which prevents fading and supports your product’s long-term value proposition.

- Critical Performance Metrics: High-quality acetate has excellent tensile strength and is heat-adjustable. This allows opticians to provide custom fittings, a service that enhances customer loyalty and reduces returns. You must verify that your supplier’s acetate maintains color stability for 5-7 years under normal UV exposure.

Critical Warning: Lower-grade acetate can lead to color fading, surface crazing, and dimensional instability. This directly impacts your warranty costs and damages brand reputation. Demand material source verification before committing to production.

TR90 (Grilamid): The Standard for Performance and Lightweight Comfort

TR90 is a Swiss-engineered thermoplastic polyamide designed for applications where durability and comfort are paramount. Its exceptional strength-to-weight ratio makes it ideal for sports, children’s, and active lifestyle eyewear. For your brand, TR90’s cost-effectiveness enables aggressive pricing strategies while maintaining the quality needed to compete in performance-driven markets.

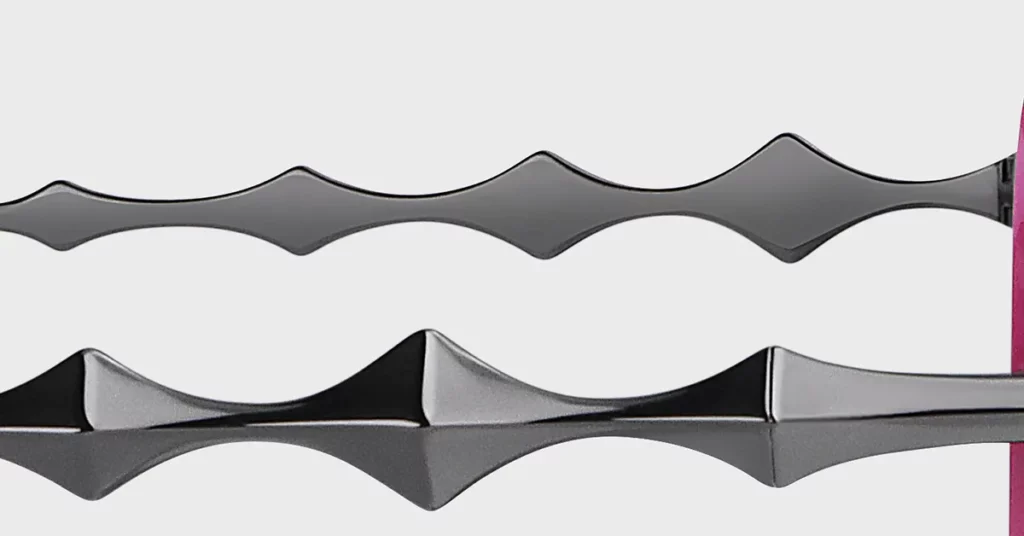

- Deconstructing the Material: TR90 combines nylon polymers with additives to achieve superior flexibility and impact resistance. Its molecular structure is engineered to absorb and distribute impact, which is why it’s the material of choice for safety and children’s eyewear, where durability is a primary selling point.

- The Performance Advantage: TR90 frames possess an inherent shape memory, allowing them to bend significantly and return to their original form. This extreme flexibility drastically reduces breakage rates, which directly lowers your warranty claim expenses and boosts customer satisfaction.

- Critical Performance Metrics: TR90 frames are featherlight, typically weighing 8-10 grams—a 50% reduction compared to standard plastics. This provides a tangible comfort benefit for the end-user. The material also resists UV degradation and common chemicals, ensuring product integrity across global climates.

Best Practice: You must specify the inclusion of UV stabilizers during manufacturing. This small step is critical for maximizing long-term performance and protecting your brand against claims of fading or material degradation.

Metal Alloys: The Choice for Minimalist and High-Tech Designs

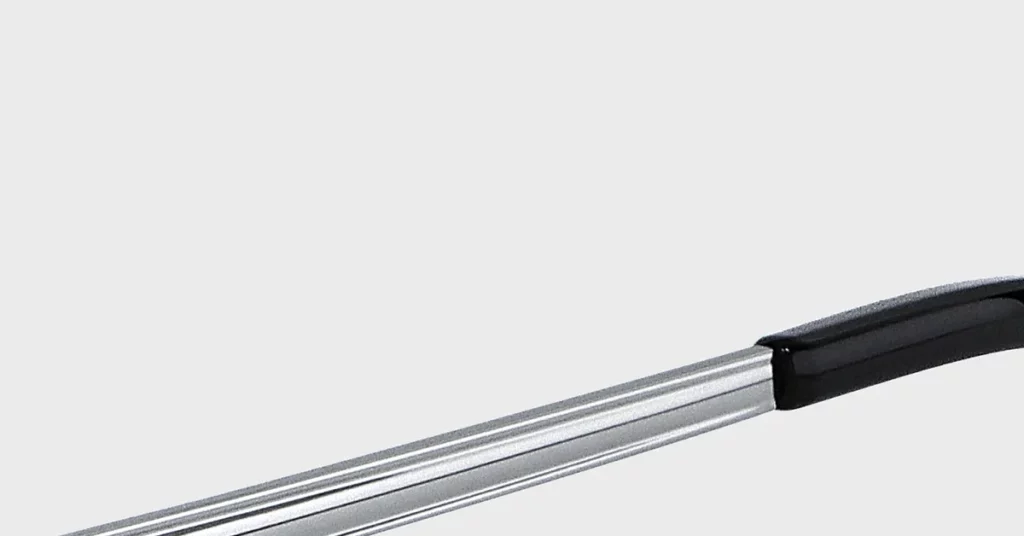

Metal frames offer unparalleled design freedom for thin profiles and intricate shapes that are impossible to achieve with polymers. The category spans from economical stainless steel to premium titanium, allowing you to target diverse market segments. Metal’s inherent strength supports minimalist aesthetics and precision engineering, appealing to professional, tech-focused, and design-conscious consumers.

- Deconstructing the Options: Your choice of metal alloy is a direct trade-off between cost and performance. Titanium is the premium, hypoallergenic option with a superior strength-to-weight ratio. Stainless steel offers reliable corrosion resistance at a moderate cost, while Monel is a cost-effective solution for volume production.

- The Design Advantage: Metal’s strength enables ultra-thin profiles (as fine as 1.2mm wire) that are structurally sound. This allows you to create sleek, architectural designs that command attention and support a modern, high-tech brand narrative.

- Critical Performance Metrics: When evaluating metals, focus on the cost-versus-weight of titanium, the corrosion resistance of stainless steel, and the verified hypoallergenic properties of both. For example, demanding Type 316L stainless steel ensures superior corrosion resistance, which is a key factor for long-term durability.

Pro Tips: Specify surface treatments like ion plating (IP) or powder coating. This enhances corrosion resistance and expands your color options, allowing for greater design differentiation without compromising the base metal’s performance.

The Manufacturing Landscape in China

Acetate Production: Artisanal Milling and Hand-Finishing

Acetate frame production is a subtractive process that combines CNC milling with labor-intensive hand-finishing. This method produces superior quality but comes with higher costs and longer lead times. You must factor these realities into your financial planning and inventory management.

- Raw Material Sources: Your choice of acetate source is a branding decision. Italian acetate (Mazzucchelli) commands the highest price ($150-200/kg) and reinforces a luxury narrative. Japanese acetate ($100-150/kg) is known for precision. Top-tier Chinese acetate ($30-80/kg) now offers quality approaching Japanese standards at a significant cost advantage.

- Manufacturing Method: CNC milling from cured blocks allows for maximum design freedom and a superior finish but is slower. Injection-molded acetate is a lower-cost alternative for high-volume orders but sacrifices the customization potential and rich look of milled acetate.

- Key Finishing Stages: The duration of barrel tumbling dictates smoothness, while manual polishing provides lustre. The most critical, and often overlooked, stage is hinge insertion. You must demand precise drilling and fitting to ensure long-term functional durability.

The Bottom Line: The high per-unit cost ($15-35) and long lead times (45-60 days) for acetate require a premium pricing strategy. This material is best suited for small-batch production (300-500 units) for luxury, bespoke, or heritage fashion brands.

TR90 Production: High-Efficiency Injection Molding

TR90 manufacturing uses precision injection molding for high efficiency, scalability, and quality consistency. This automated process reduces labor costs, making it ideal for large production runs and competitive pricing.

- Raw Material Sources: Your focus here must be on supplier reliability. Demand evidence of consistent TR90 pellet quality, specifically moisture content below 0.1% and a stable melt flow index. This ensures predictable processing and a consistent final product.

- The Molding Process: A significant upfront cost is the precision steel tooling (mold), which can range from $5,000 to $15,000. However, a well-maintained mold can produce over 500,000 units, making the amortized cost per frame minimal for large orders.

- Key Finishing Stages: Branding on TR90’s non-porous surface is achieved with pad printing or durable sprayed coatings. You must verify the adhesion of these applications. Specify UV-cured inks for pad printing, as they offer superior abrasion resistance compared to solvent-based inks.

The Bottom Line: TR90’s low per-unit cost ($3-8) and rapid production cycles (15-25 days) support high-volume, scalable production. This material is ideal for performance, active lifestyle, and children’s eyewear where durability and value are the primary drivers.

For Example: A 10,000-unit TR90 frame order may achieve a $5.50 per-unit cost, whereas a 2,000-unit order would be $7.50. This demonstrates the significant economies of scale inherent to injection molding.

Metal Production: Precision Engineering and Assembly

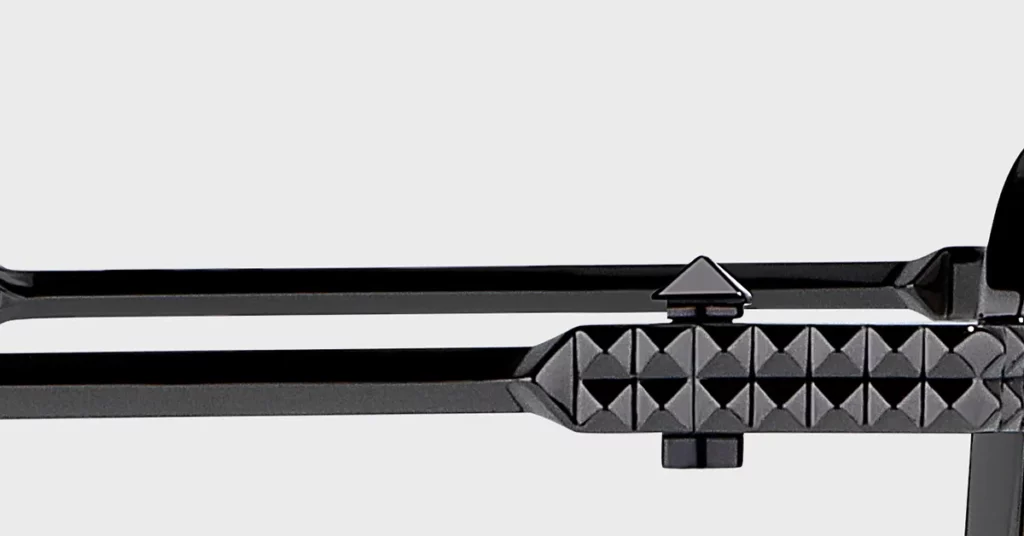

Metal frame manufacturing is an engineering-driven process combining fabrication techniques like stamping and laser cutting with precision assembly. This gives you immense design flexibility for intricate shapes but requires stringent quality control, especially at assembly points.

- Component Fabrication: You can choose from several techniques. Stamping is cost-effective for high-volume production of frame fronts. Laser cutting offers design flexibility for intricate patterns. CNC machining delivers maximum precision for complex components.

- The Assembly Process: The integrity of your metal frames depends on the joint strength. You must vet a partner’s expertise in soldering versus laser welding. Laser welding provides superior strength with minimal heat distortion, making it the preferred method for high-performance or premium titanium frames.

- Surface Finishing: Your choice of finish impacts both durability and aesthetics. Ion Plating (IP) offers exceptional wear and corrosion resistance. Powder coating is a cost-effective and durable option. Anodizing is ideal for aluminum, creating an integral protective layer.

The Bottom Line: Metal offers supreme design flexibility. Your quality control program must be ruthlessly focused on the integrity of welds and solder points and the adhesion and uniformity of coatings and plating.

B2B Decision Matrix: A Strategic Comparison

Your material choice is a strategic trade-off. The following tables break down the decision along three critical business axes: Cost Structure, Aesthetic Capabilities, and End-User Performance.

Comparing by Cost Structure and Market Position

| Material Category | Raw Material Cost | Manufacturing Cost | Tooling Amortization | Total Unit Cost | Target Retail Price |

| Premium Acetate | $4-8 | $8-15 | $2-5 | $15-35 | $150-400 |

| TR90 Polymer | $1-2 | $2-4 | $1-2 | $3-8 | $40-120 |

| Stainless Steel | $2-4 | $4-8 | $2-3 | $8-15 | $80-250 |

| Titanium Alloy | $6-10 | $6-12 | $3-5 | $15-25 | $200-500+ |

Key Metric: The landed cost analysis reveals that manufacturing complexity and labor are the primary cost drivers. Acetate’s high cost demands luxury market positioning, while TR90’s efficiency enables competitive pricing in mass-market or performance segments.

Comparing by Aesthetic Capabilities and Brand Alignment

| Material | Color Depth & Type | Pattern Options | Brand Story Alignment |

| Acetate | Excellent (Embedded) | Extensive (Lamination) | Craftsmanship, Heritage, Luxury |

| TR90 | Moderate (Compounded/Sprayed) | Limited (Surface Application) | Technology, Performance, Safety |

| Metal | Good (Plating/Coating) | Moderate (Etching/Finishing) | Timeless Design, Minimalism, Engineering |

Pro Tips: Your material choice must reinforce your brand narrative. An acetate frame supports a story of artisanal quality. A TR90 frame supports a story of Swiss-engineered technology. A metal frame supports a story of timeless, architectural design. Misalignment confuses consumers and undermines brand equity.

Comparing by End-User Performance and Durability

| Attribute | Acetate | TR90 | Metal |

| Flexibility | Rigid but heat-adjustable | Extremely flexible (shape memory) | Rigid (permanently adjustable) |

| Weight | Substantial / Heavy | Featherlight | Light to Moderate |

| Adjustability | High (by optician with heat) | Low (resists adjustment) | High (by optician with tools) |

| UV Aging | Good (premium grades) to Poor | Excellent | Dependent on coating quality |

| Hypoallergenic | Yes | Yes | Yes (Titanium, specific SS) |

Critical Warning: The long-term aging characteristics are a key differentiator. Premium acetate maintains its color for 5-7 years, but lower grades will fade. TR90 shows exceptional stability. Metal’s longevity is entirely dependent on the quality of its surface finish.

A Framework for Strategic Sourcing from China

Vetting Manufacturing Partners

- Locate Suppliers: Use industry fairs like the Canton Fair and Hong Kong Optical Fair for initial vetting. Focus your search on key manufacturing clusters like Wenzhou (all materials) and Linhai (specializing in TR90/injection molding).

- Validate Quality Systems: Demand evidence of current ISO 9001:2015 certification. This is the baseline indicator of a factory’s ability to maintain process consistency, which is fundamental to protecting your investment.

- Evaluate Social Compliance: For global brands, audits for BSCI or Sedex are non-negotiable. This mitigates supply chain risk and protects your brand’s reputation regarding labor standards and environmental responsibility.

- Assess Engineering Capability: Your partner’s team must have proficient English and demonstrate expertise in interpreting technical drawings. Miscommunication on a CAD file can lead to thousands of dollars in tooling errors and production delays.

Navigating Financial and Regulatory Complexities

- Calculate Landed Cost: Your unit price is only the beginning. You must factor in Minimum Order Quantities (MOQs), tooling fees ($400-$1200+), Incoterms (FOB is preferable to EXW), tariffs, and shipping to understand your true cost.

- Ensure Product Safety Compliance: You are responsible for meeting international standards. This includes ANSI Z87.1 (US), EN ISO 12312-1 (EU), REACH, and California Proposition 65. Establish testing protocols early in development to prevent costly market entry failures.

- Protect Intellectual Property (IP): Your IP is your brand’s most valuable asset. Always use a China-enforceable Non-Disclosure Agreement (NDA). Register your designs and trademarks in China before sharing them with any potential partner.

Implementing a Material-Specific QC Protocol

A generic checklist is insufficient. Your quality control protocol must be tailored to the specific failure points of your chosen material.

Acetate QC Checkpoints

- Inspect for color consistency against your master sample under controlled lighting.

- Check for material bubbles or impurities using transmitted light.

- Verify polish uniformity and the absence of scratches or tool marks.

- Scrutinize lamination alignment to ensure patterns are seamless.

TR90 QC Checkpoints

- Test for uniform mold flow by checking for sink marks or short shots.

- Conduct cross-hatch adhesion tests on all sprayed coatings and printed logos.

- Perform batch tests on material flexibility to prevent brittleness from improper drying or processing.

Metal QC Checkpoints

- Scrutinize the integrity and uniformity of all welds and solder points.

- Measure the thickness and test the adhesion of all plating and coatings.

- Use a jig to verify overall frame alignment and symmetry to ensure proper optical function.

Core Component QC

- Verify lens compliance for UV protection and optical clarity (e.g., ANSI Z80.3).

- Test hinge hardware durability with automated cycle testing to simulate long-term use.

Conclusion

Selecting a sunglass material is a strategic decision that defines your brand and business. The choice between the artisanal luxury of acetate, the lightweight performance of TR90, and the engineered minimalism of metal must be a deliberate calculation of cost, aesthetics, performance, and brand narrative. Success in sourcing from China requires a ruthless focus on vetting partners, defining material-specific QC, and protecting your IP.

At Kssmi, we provide the strategic guidance to align these complex variables for market success. Contact Kssmi to co-develop a market-leading eyewear collection that makes the right material choice for your brand.

Frequently Asked Questions

1. How does frame adjustability differ between acetate and TR90?

Acetate offers superior adjustability with heat, allowing opticians to provide a custom fit. This is ideal for high-end optical retail. TR90’s shape-memory resists adjustment, making it better suited for direct-to-consumer models where a “one-size-fits-most” approach is sufficient.

2. What are common QC failure points for acetate vs. TR90 frames?

Hand-polished acetate frames often fail due to inconsistent polishing, color variations between batches, and lamination defects. Injection-molded TR90 frames more commonly exhibit failures from incomplete mold filling (short shots), sink marks, and poor coating adhesion on the non-porous surface.

3. What are the trade-offs between Ion Plating (IP) and powder coating on metal?

IP offers superior durability and wear resistance, justifying its higher cost by reducing long-term warranty claims. Powder coating is more economical but may chip or fade faster, making it a trade-off between a lower initial product cost and potentially lower long-term customer satisfaction.

4. How can I verify a supplier’s expertise in all three materials?

Demand to see distinct, dedicated production lines. A genuine multi-material expert will have separate CNC milling centers for acetate, injection molding presses for TR90, and metal fabrication equipment like laser welders. They will also have material-specific QC tools, not just generic calipers.

5. How does the aging process differ between the three materials?

Premium acetate maintains its color for 5-7 years before any potential fading. TR90 shows exceptional stability in both color and flexibility over its lifespan. The aging of a metal frame is entirely dependent on its finish; a quality IP coat can last for decades, while a cheap paint job can fail in 2-3 years.