What Are Acetate Sunglasses?

To be clear, acetate sunglasses are premium eyewear crafted from cellulose acetate, a plant-based biopolymer. This material is prized for its rich color possibilities, hypoallergenic properties, and lightweight feel. Unlike standard plastics, you cut acetate frames from solid blocks, which allows for superior durability, custom fit adjustments, and a luxurious finish essential for high-end brands.

Foundational Analysis: Acetate as a Core Strategic Eyewear Material

Understanding Cellulose Acetate: A B2B Primer

Definition: Cellulose acetate is a semi-synthetic biopolymer derived from renewable plant sources like cotton fibers and wood pulp. Unlike petroleum-based plastics, it offers a biodegradable and hypoallergenic foundation. This plant-based origin positions acetate as a responsible alternative while delivering the durability and design flexibility you require for premium manufacturing.

The production process begins with cellulose purification, followed by a controlled acetylation with acetic anhydride. This chemical modification creates a thermoplastic polymer ready for compounding. Plasticizers and stabilizers are added to the resulting flakes, creating the high-grade granules used in eyewear production.

Critical Warning: The quality of the source cellulose directly dictates the final properties of the acetate. Premium suppliers like Mazzucchelli and Takiron invest heavily in sourcing high-grade, consistent cellulose to guarantee uniform optical and mechanical performance in your final product.

Acetate vs. Petroleum-Based Polymers

Acetate’s classification as a semi-synthetic thermoplastic provides distinct strategic advantages. It retains the renewable credentials of a natural material while offering the processability of an engineered plastic. The material shows excellent biocompatibility, with ISO 10993 testing confirming its hypoallergenic properties for prolonged skin contact, a sharp contrast to polymers that may contain allergens.

Historical Context: The 1940s Shift to Acetate

Acetate became the standard in eyewear manufacturing during the 1940s. It was the solution to the persistent problems of early plastics, which were brittle and caused skin irritation. This 80-year history established acetate’s reputation for reliability and comfort, building consumer trust that you can leverage in your brand narrative today.

Pro Tips: You should use acetate’s historical significance in your marketing. The proven track record of safe, comfortable wear provides powerful differentiation against newer, less-established synthetic materials.

Strategic Material Benchmarking for Your Portfolio

Acetate vs. Injection-Molded Plastic

Acetate frames exhibit measurable superiority over their injection-molded counterparts. While you can apply color to injection-molded frames with surface coatings, acetate’s rich coloration comes from embedded pigments that run through the entire material. This results in superior durability; acetate colors maintain their vibrancy for years while coated plastics fade or chip.

| Feature | Acetate Frames | Injection-Molded Plastic |

| Color Depth | Rich, complex, and embedded throughout the material | Standard, surface-level, and prone to fading or chipping |

| Manufacturing | Cut from solid, layered blocks (subtractive) | Molded from liquid polymer (additive) |

| Durability | High tensile strength and flexibility | Moderate durability, can become brittle |

| Adjustability | Fully heat-adjustable for a custom fit | Limited to no adjustability |

| Material Waste | 50-75% | 5-10% |

Acetate vs. Performance Polymers (TR90, Nylon)

You must differentiate acetate from performance polymers like TR90 and nylon, which are engineered for sports applications. Acetate’s strategic advantage is in its aesthetic sophistication, color complexity, and the premium hand-feel required for fashion and luxury positioning. Performance polymers lack the visual depth and high-gloss finish that acetate provides.

| Attribute | Acetate Frames | Performance Polymers (TR90, Nylon) |

| Primary Use Case | Fashion, Luxury, Lifestyle | Sports, Safety, Performance |

| Aesthetics | Unmatched color depth, patterns, high-gloss finish | Functional, typically single-color, matte finish |

| Flexibility | Moderate flexibility with shape memory | Extreme flexibility, designed to bend |

| Impact Resistance | Good | Excellent, designed for high impact |

| Hand-Feel | Substantial, warm, luxurious | Lightweight, technical, plastic-like |

Best Practice: You should position acetate for your lifestyle, fashion, and luxury segments. Reserve performance polymers for any sports-specific product lines. This segmentation maximizes each material’s inherent strengths and avoids competing on metrics where one is clearly superior.

Acetate vs. Metal Frames: A Comparison

Acetate presents clear advantages over metal frames in design flexibility and hypoallergenic properties. While metal excels in minimalist structures, you gain superior color options, pattern possibilities, and integrated comfort with acetate.

| Attribute | Acetate Frames | Metal Frames |

| Color Options | Virtually unlimited with complex patterns and layers | Limited to plating and coating colors |

| Adjustability | Heat-moldable for a fully custom, integrated fit | Mechanical adjustment (e.g., nose pads, temples) |

| Allergenic Potential | Hypoallergenic, ideal for sensitive skin | Potential for nickel sensitivity reactions |

| Weight Distribution | Evenly distributed across the entire frame | Concentrated at specific contact points |

| Design Complexity | High capability for patterns and multi-tonal effects | Best for minimalist, thin, geometric designs |

Sustainability: Bio-Acetate and Market Perceptions

Defining Bio-Acetate: Composition & Claims

Definition: Bio-acetate is an advancement that uses bio-based plasticizers from renewable sources instead of traditional petroleum-based additives. Standard acetate already has 40-60% bio-based content from its cellulose. Bio-acetate formulations increase this to 60-100% by replacing petroleum-derived plasticizers, achieving a higher level of sustainability.

Bio-Acetate: Performance Equivalence

You should know that bio-acetate maintains performance equivalence with standard acetate. Material testing confirms comparable tensile strength, impact resistance, and optical clarity. Production testing shows bio-acetate processes identically in cutting, heating, and polishing. Your integration of bio-acetate into existing manufacturing workflows can be seamless, without quality compromises.

Mitigating Greenwashing Risk with Bio-Acetate

Critical Warning: Not all materials marketed as “bio-acetate” offer significant environmental benefits. You must verify ISCC (International Sustainability and Carbon Certification) compliance, renewable content percentages, and biodegradability test results. Some formulations may contain only marginal renewable content while making aggressive sustainability claims.

Effective sourcing of bio-acetate requires rigorous verification. Demand documentation of renewable feedstock sources, plasticizer composition, and end-of-life degradation testing (e.g., ISO 14855). This protects your brand from the risks of greenwashing.

Leveraging Acetate for Market Advantage

Translating Properties into Consumer Value

The Hypoallergenic Advantage

Acetate’s hypoallergenic properties create a significant market opportunity. You can target consumers with sensitive skin or metal allergies, as acetate frames cause fewer allergic reactions. Communicate this benefit by highlighting the material’s plant-based origins and suitability for extended wear without making unsubstantiated medical claims.

Lightweight Construction for All-Day Comfort

Key Metric: Acetate frames typically weigh 15-25% less than comparable metal designs while maintaining superior structural integrity. Its density of 1.15-1.35 g/cm³ provides an optimal weight balance for all-day comfort, reducing pressure points and fatigue, which is a powerful selling point for prescription wearers.

Durability & Flexibility: Reducing Warranty Claims

Acetate’s molecular structure gives it superior flexibility compared to injection-molded plastics, dramatically reducing breakage rates. This durability translates directly into fewer warranty claims and higher customer satisfaction. In my two decades of crafting eyewear, I’ve seen firsthand how this material property saves brands significant operational costs.

The Science of Adjustability for Custom Fit

Acetate’s thermoplastic nature is a core functional benefit. You empower opticians to achieve a perfect custom fit by heating the frame to 50-60°C and making precise adjustments. This capability eliminates discomfort and improves optical performance by ensuring correct lens positioning, which directly increases customer satisfaction.

Best Practice: Always train your retail partners in proper acetate adjustment techniques. A well-trained optician can resolve over 90% of fit issues on the spot, building loyalty and reducing returns.

Aesthetic Possibilities for Differentiation

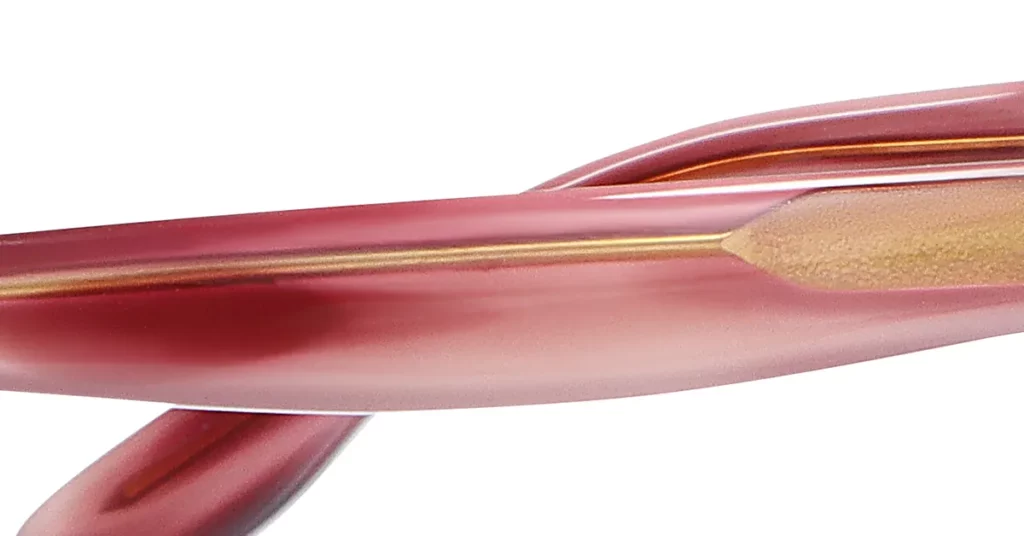

Unmatched Color Depth via Embedded Layering

Acetate’s block construction enables color to be layered throughout the material, creating a visual depth that surface coatings cannot replicate. This embedded approach makes the color permanent, preventing the fading or chipping that plagues coated frames. Premium acetate blocks may incorporate 5-8 distinct color layers for rich, dynamic effects.

Pattern Creation: Tortoiseshell, Custom Colors

- Tortoiseshell (Havana): This iconic acetate aesthetic requires the precise layering of amber, brown, and black acetate sheets. Italian manufacturers like Mazzucchelli have perfected this art, achieving patterns with unparalleled authenticity.

- Custom Colorways: You can achieve powerful brand differentiation with exclusive color combinations. Leading manufacturers offer custom block creation for minimum order quantities (typically 500-1000 pieces), allowing you to develop a signature look.

- Gradients: The layering process also allows for subtle, seamless color transitions within the frame material itself, a sophisticated effect that is highly valued in luxury eyewear.

For Example: Mazzucchelli offers over 3,000 standard color combinations and provides a custom development service for unique brand requirements. The custom process typically requires 6-8 weeks for block creation on top of standard manufacturing timelines.

Finish Varieties: High-Gloss, Matte, & Brushed

You can expand your design palette with different finishing techniques, each offering a distinct aesthetic. Polishing determines the final surface texture and requires specific manufacturing expertise.

| Finish Type | Process | Aesthetic Outcome |

| High-Gloss | Multiple polishing stages with progressively finer compounds. | A mirror-like, reflective finish that highlights color depth. |

| Matte | Controlled surface texturing or bead blasting. | An even, non-reflective appearance that reduces fingerprints. |

| Brushed | Directional texturing with specialized abrasives. | Subtle linear patterns that add texture and dimension. |

Strategic Use of Transparency in Design

Clear and translucent acetate allows for sophisticated, minimalist aesthetics that align with modern design trends. These options range from crystal-clear frames to subtly tinted translucents. Transparent frames demand exceptional material quality, as any internal imperfection becomes visible, making them a hallmark of premium production.

Mastering Manufacturing & Quality Control

From Raw Material to Finished Frame

Production Cycle: Acetone Paste to Cured Blocks

Acetate frame production begins by dissolving cellulose acetate flakes in acetone to create a paste. This colored paste is rolled into thin sheets, which are then layered and laminated under immense pressure (50-100 tons) and heat (120-150°C) to form solid blocks. This process must be precisely controlled to prevent defects.

Subtractive Manufacturing vs. Injection Molds

The Bottom Line: You must account for the fact that subtractive manufacturing creates 50-75% material waste as frames are cut from solid acetate blocks. This waste factor directly impacts your unit cost but is the price of admission for the superior density, color complexity, and finish that this method allows.

Hallmarks of Craftsmanship: Hand-Finishing

Premium acetate finishing involves multiple, labor-intensive stages:

- Rough Tumbling: Frames are tumbled for 12+ hours in rotating barrels with large wood chips to remove cutting marks.

- Medium & Fine Tumbling: Subsequent tumbling stages use progressively smaller wood pellets and polishing compounds for up to 60+ additional hours to achieve a smooth surface.

- Hand Polishing: Always demand hand-polishing for detail areas. This final buffing stage is what creates a truly flawless, high-gloss finish and separates premium products from mass-market goods.

Structural Integrity: Core Wires & Rivets

You must ensure proper structural reinforcement. Metal wire cores are inserted into heated acetate temples to provide rigidity and shape retention. For assembly, prioritize suppliers who use real rivets or high-quality threaded screws over adhesives for a durable, repairable, and long-lasting final product.

Mitigating Critical QC Failure Points

The Importance of Curing Time

Critical Warning: Proper acetate curing takes 1-8 weeks in temperature-controlled ovens (60°C). Rushed curing schedules to meet a deadline create immense liability. Insufficiently cured acetate will continue to leach solvents, causing dimensional instability, brittleness, and potential skin irritation. Demand documentation of full curing cycles from every supplier.

Material Brittleness from Rushed Curing

Inadequately cured acetate leads to catastrophic failures. The most common is stress cracking around the lens grooves, often occurring 3-6 months after manufacturing. These delayed failures generate warranty claims and cause serious damage to your brand’s reputation for quality.

The Manufacturing Waste Factor (Up to 75%)

You must factor acetate’s high waste percentage into your costing and sustainability plans. Leading manufacturers implement waste reduction strategies like optimized cutting patterns and developing recycled acetate options. Recycled acetate, however, typically requires blending with virgin material to maintain performance standards.

Vetting Chemical Safety (EU REACH Compliance)

Key Metric: You must secure documentation confirming compliance with global standards like EU REACH. This requires analysis of all inputs—plasticizers, stabilizers, and colorants—for Substances of Very High Concern (SVHC), with concentrations below 0.1% by weight. Your global compliance checklist should also include US CPSIA (lead and phthalates) and ISO 10993 (biocompatibility).

Strategic Sourcing & Supplier Vetting

Evaluating the Global Acetate Supply Chain

Regional Specialization: Italian vs. Japanese

The global supply of premium acetate is led by Italian manufacturer Mazzucchelli and Japanese producer Takiron. Each offers distinct characteristics, and your choice must align with your brand’s positioning. Mazzucchelli is the master of rich color artistry, while Takiron is known for precision and dimensional stability.

| Property | Italian (Mazzucchelli) | Japanese (Takiron) |

| Primary Strength | Unmatched color depth and pattern artistry | Superior hardness and dimensional stability |

| Best For | Luxury fashion, aesthetically driven brands | Technical frames, minimalist designs, optical precision |

| Hardness (Shore D) | 75-80 (Softer) | 85-90 (Harder) |

| Shape Retention | Good | Excellent |

| Price Premium | 15-25% | 10-20% |

| Lead Times | 8-12 weeks | 6-10 weeks |

Pro Tips: Match your acetate supplier to your market position. If your brand story is about artistry and fashion, the aesthetic capabilities of Italian acetate are your best asset. If your brand emphasizes technical precision or durability, the dimensional stability of Japanese acetate is the superior choice.

Assessing Supplier Manufacturing Capabilities

Best Practice: Evaluate suppliers by auditing their process controls, employee training programs, and quality management systems. Prioritize suppliers with experienced workforces (average tenure >5 years) and robust QC protocols, including batch traceability and in-process monitoring. ISO 9001 certification is a baseline, but specific eyewear expertise is far more valuable.

Building a Quality-Assured Supply Partnership

Supplier Vetting Checklist

You must demand evidence of process control. Never proceed without this documentation:

- Curing temperature and time records for the last 12 months.

- Material batch testing results, including mechanical properties.

- Chemical composition verification for all inputs (REACH, etc.).

- Dimensional consistency data across multiple production lots.

- Accelerated aging test results that demonstrate long-term stability.

Key Questions for Potential Suppliers

Your discussions must address these critical operational points:

- Material Traceability: What documentation can you provide for raw material sources? How do you track batches to resolve quality issues?

- Chemical Safety: How do you verify that all plasticizers and additives comply with current international regulations like REACH?

- Waste Management: What percentage of your production waste is recycled or reprocessed? What are your waste reduction targets?

Mandatory Third-Party Testing & Inspection

Execute a third-party inspection plan. Independent quality verification from a specialized lab is your best protection against supplier quality drift. This testing is a non-negotiable step to confirm compliance with international standards before the product ships. Essential tests include impact resistance (EN 166), UV protection (EN 12312-1), and nickel release (EN 1811).

Justifying Higher Costs for Market Position

Premium acetate carries a significant cost premium over injection-molded alternatives, but this investment enables market positioning that justifies higher retail prices. The investment in superior materials and labor-intensive processes directly translates into tangible consumer value, brand differentiation, and reduced long-term costs.

The Bottom Line: Investing in premium acetate enables you to command retail prices 3-5 times higher than mass-market plastic frames. This premium is justified by superior aesthetics, comfort, and durability, which also reduces your costs from warranty claims and returns, ultimately yielding a stronger, more profitable brand.

Conclusion

Acetate’s value lies in its unique fusion of aesthetic potential, tangible consumer benefits, and a premium, sustainable story. Its embedded color, heat-adjustability, and hypoallergenic nature create powerful differentiation. To succeed, you must master its manufacturing complexities and partner with expert suppliers who can navigate the critical curing, waste, and QC protocols. For brands ready to build a superior product, a partnership with an experienced acetate manufacturer is the most direct path to market leadership.

Frequently Asked Questions

1. What is the business impact of insufficient acetate curing?

Insufficient curing creates liability from frame instability, brittleness, and chemical leaching. Failures typically occur 3-6 months post-sale, leading to costly warranty claims and significant damage to your brand’s reputation for quality.

2. What’s the difference between standard and “bio-acetate”?

Bio-acetate uses renewable, plant-based plasticizers to achieve 60-100% bio-based content, versus 40-60% in standard acetate. While performance is equivalent, you must verify ISCC certification to ensure the environmental claims are legitimate and avoid greenwashing.

3. How does Italian vs. Japanese acetate affect my product?

Italian acetate (Mazzucchelli) offers superior color artistry for fashion frames. Japanese acetate (Takiron) provides greater hardness and shape retention, ideal for technical or optical designs. Your choice directly impacts the product’s final look, feel, and performance.

4. How should I balance acetate vs. TR90 in a product line?

You should use acetate for your premium fashion and lifestyle frames where aesthetics and feel are paramount. Reserve highly flexible, impact-resistant materials like TR90 for dedicated sport or performance models. This segmentation maximizes each material’s strengths.

5. What are the primary QC failure points in acetate manufacturing?

The most critical failure points are rushed curing times, improper wire core insertion in the temples, and inconsistent polishing. You must monitor these stages through supplier audits, documentation review, and third-party inspections to prevent defects.