The Advantages and Disadvantages of Nylon Sunglasses Lenses

Nylon lenses offer exceptional optical clarity, achieving an Abbe value up to 52, which is vastly superior to polycarbonate’s 30. This means you get sharper, distortion-free vision. They are also extremely lightweight and flexible, making them ideal for high-end, comfortable eyewear. Their main drawbacks are a higher cost and lower scratch resistance without a protective coating.

What Are Nylon Lenses? A Material Science Guide

To make the right choice, you first need to understand what nylon actually is. It’s not just one material, but a family of advanced polymers, each with properties that make it uniquely suited for premium eyewear.

Defining Nylon as a High-Performance Polymer

At its core, nylon lens material is a type of polyamide, which is a high-performance thermoplastic known for its incredible strength and flexibility. This means that unlike more brittle plastics, nylon can bend and flex under stress without breaking. Think of it like the difference between a dry twig that snaps easily and a green branch that can bend significantly before reaching its breaking point. This resilience is what gives nylon its real-world durability.

The Specific Grades Used in Eyewear

You should know that not all nylon is suitable for optical use. Eyewear manufacturers use specialized, transparent grades like Grilamid TR 90 and Trogamid CX. These are engineered for superior optical purity and stability. Some brands are also turning to bio-based nylons, derived from castor oil, to offer a more sustainable alternative to petroleum-based plastics.

How Precision Injection Molding Creates Clarity

Modern nylon lenses are made using a process called precision injection molding. This technique involves injecting molten polyamide into highly polished lens molds under extreme pressure. The primary benefit for you is consistency. This process allows for complex lens curves and ensures every single lens meets exact optical standards, which is critical for large-scale production runs.

Key Terms for Confident Decision-Making

To speak confidently with manufacturers, you need to master a few key technical terms. Understanding this language will allow you to specify your needs precisely and evaluate materials like an expert.

Definition: The Abbe value is the industry-standard measure for optical clarity, specifically rating how much a lens disperses light. A higher number means less chromatic aberration, or colored fringing around objects.

Key Metric: Nylon lenses have an excellent Abbe value between 45 and 52, while polycarbonate typically sits around 30. Since the human eye can’t detect color fringing above a value of 40, nylon delivers vision that is essentially distortion-free.

Definition: Specific gravity is a simple measure of a material’s density. A lower value means the material is lighter, which is a massive factor in wearer comfort.

Pro Tip: Nylon’s extremely low specific gravity of around 1.1 g/cm³ makes it one of the lightest lens materials available. This allows you to create bold, oversized designs without the frames feeling heavy or causing pressure on the nose and ears.

Definition: Impact resistance measures a lens’s ability to withstand direct force without shattering. The key safety standard to know is ANSI Z87.1, which is the benchmark for safety eyewear in the United States.

Remember This: While polycarbonate is famous for its impact resistance, high-grade nylon also meets these crucial safety standards, giving you a material that is both safe and optically superior.

The Core Advantages of Nylon Lenses

Brands choose nylon for three primary reasons: unmatched clarity, lightweight comfort, and design flexibility. Understanding these benefits will help you market your products effectively.

Advantage 1: Unmatched Optical Clarity

The single most important advantage of nylon is its superior visual performance. You are giving your customer a view that is measurably sharper and more accurate.

A high Abbe value means the lens bends light into its constituent colors far less than materials like polycarbonate. This reduces the distracting “color fringing” that can appear around high-contrast objects. Simple Analogy: The visual difference is like watching a movie in brilliant 4K High Definition versus an old standard-definition broadcast. The clarity and color fidelity are in a completely different league.

Advantage 2: Extreme Lightweight Comfort

The weight of a pair of sunglasses is not a minor detail; it defines the all-day wearing experience. Nylon’s low density is a game-changer for comfort.

Nylon lenses are more than twice as light as traditional mineral glass and noticeably lighter than polycarbonate. This significant weight reduction eliminates pressure points on the nose and ears, preventing wearer fatigue. Best Practice: Always highlight this lightweight benefit when marketing sports eyewear or large fashion frames, as it’s a key factor for customer satisfaction and repeat purchases.

Advantage 3: Superior Durability & Flexibility

Nylon’s unique molecular structure provides a powerful combination of toughness and flexibility, opening up more advanced design possibilities.

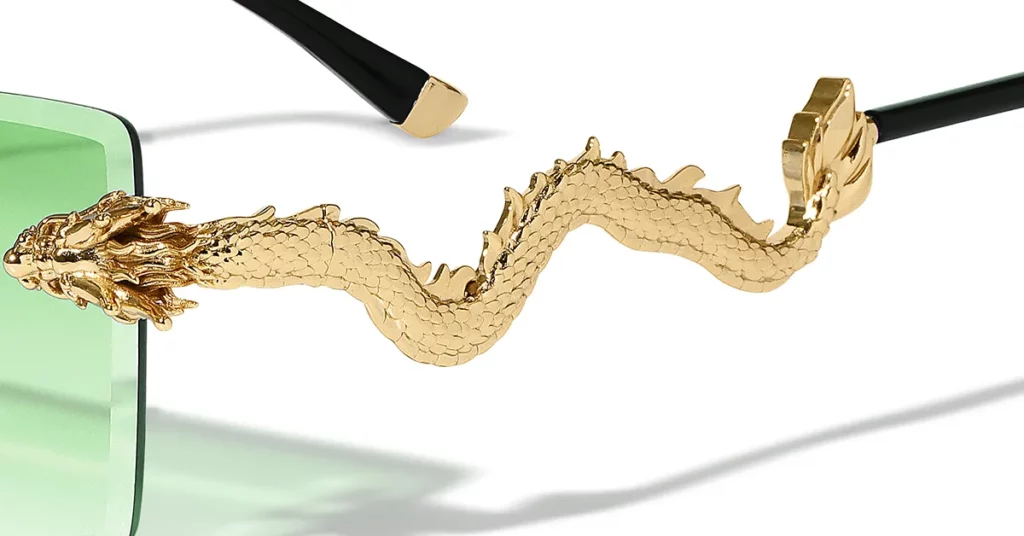

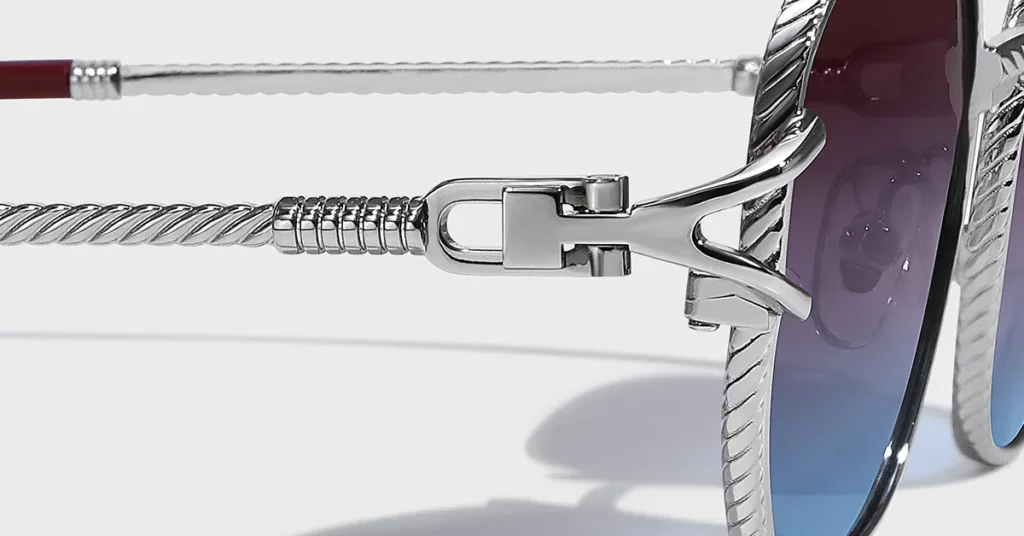

The material has excellent resistance to chemicals, meaning it won’t be damaged by common sunscreens or skin oils. Its flexibility makes it the ideal choice for rimless and semi-rimless frames, where the lens itself must withstand the stress of being drilled and mounted. This dramatically reduces the risk of stress fractures during assembly or everyday use.

The Practical Disadvantages of Nylon

No material is perfect. To make an informed choice, you must also understand nylon’s limitations and how to mitigate them.

Disadvantage 1: Lower Scratch Resistance

The primary trade-off for nylon’s flexibility is a softer surface. In its raw, uncoated state, nylon is more prone to fine scratches than harder materials like glass.

Critical Warning: You should never specify uncoated nylon lenses. A quality scratch-resistant hard coat is absolutely non-negotiable. This modern surface treatment effectively solves the scratch issue, allowing you to benefit from nylon’s superior optics and flexibility without compromising on durability.

Disadvantage 2: Higher Material & Production Cost

Premium performance comes at a premium price. Nylon lenses are more expensive to produce than their polycarbonate counterparts.

This higher cost stems from the more advanced polymer and the precision required in the manufacturing process. You should view this not as a simple expense, but as a strategic investment. The superior performance of nylon justifies a higher retail price and supports a premium brand position in the market.

Disadvantage 3: Potential for Minor Water Absorption

In extremely humid environments, nylon material has the potential to absorb a minuscule amount of moisture from the air.

Remember This: For nearly all eyewear applications, this effect is entirely negligible. It does not impact the optical performance, structural integrity, or fit of the glasses in any way your customer would ever notice. It’s a technical characteristic, not a real-world flaw.

Nylon vs. Other Lens Materials: A Comparison

Use this matrix to make a data-driven choice that aligns with your product’s goals. Start by identifying your primary goal—is it ultimate optical performance, maximum value, or something in between?

| Feature | Nylon / Polyamide | Polycarbonate | Trivex | CR-39 Plastic | Mineral Glass |

| Optical Clarity (Abbe) | Excellent (45-52) | Good (30) | Very Good (43-45) | Excellent (58) | Excellent (58) |

| Impact Resistance | Very High | Highest | Very High | Low | Very Low |

| Weight / Comfort | Lightest | Lightweight | Lightest | Light | Heavy |

| Scratch Resistance | Fair (Requires Coating) | Poor (Requires Coating) | Fair (Requires Coating) | Good | Best |

| UV Protection | Inherent | Inherent | Inherent | Requires Coating | Requires Coating |

| Ideal Frame Type | All Types, esp. Rimless | Safety & Sport | All Types | Full Frame | Full Frame |

| Typical Cost | High | Low | Medium | Low | High |

The Bottom Line: This matrix clearly shows that nylon occupies a unique sweet spot. It delivers optical clarity that rivals glass while providing the impact resistance and lightweight comfort needed for modern performance and fashion frames.

The Cost vs. Clarity Trade-Off

If nylon is so good, why do many major brands still use polycarbonate? The decision often comes down to a strategic balance of performance, cost, and marketing.

For many mainstream applications, polycarbonate’s performance is “good enough.” The average consumer may not perceive the difference in optical clarity during casual wear, making the cost savings a more powerful driver. Furthermore, many brands have established supply chains optimized for polycarbonate, and switching would require significant investment.

Common Mistake: Don’t assume a material’s technical sheet is the only thing that matters. Powerful marketing, like Oakley’s “High Definition Optics,” can build a strong brand perception around polycarbonate that convinces consumers of its quality, regardless of its Abbe value.

When to Choose Nylon for Your Brand

Your material choice should be a deliberate extension of your brand strategy. Match the technical benefits of nylon to your target customer’s expectations.

- Insist on nylon when… your brand promises professional-grade performance and the superior optical clarity is a key selling point.

- Insist on nylon when… your designs feature large, oversized, or minimalist rimless styles where lightweight comfort is essential to the aesthetic.

- Insist on nylon when… you want to create a premium product tier that offers a measurable upgrade over lower-priced competitors.

The Bottom Line: Choose nylon when its clear advantages in optical performance, weight, or design flexibility justify a higher price for your target market. Stick with polycarbonate when absolute cost control or extreme shatter resistance are your primary concerns.

Conclusion

Nylon sunglass lenses offer a carefully engineered balance of glass-like optical clarity, exceptional lightweight comfort, and the design flexibility needed for modern eyewear. While they require a greater investment and a mandatory hard coat, their superior performance makes them the intelligent choice for brands aiming to deliver a premium, high-performance product. This material choice is a clear statement of quality that discerning customers will see and feel.

For a more advanced analysis of manufacturing and supply chain factors, explore our complete A Manufacturer’s Framework for High-Performance Lens Material Selection.

Frequently Asked Questions

1. Are nylon lenses the same as TR-90 nylon frames?

No, they are different applications of the same polymer family. Nylon used for frames is optimized for maximum flexibility and durability. The nylon used for lenses, like Grilamid TR 90, is engineered for the highest possible optical clarity and transparency.

2. Can you get polarized or photochromic nylon lenses?

Absolutely. Nylon is an excellent base material that readily accepts advanced treatments. Polarization is a filter applied to the lens, and functional additives for features like photochromic (light-adjusting) performance are fully compatible with nylon substrates.

3. How do I clean nylon lenses to prevent scratches?

Always treat nylon lenses like any other premium optical surface. Use a clean microfiber cloth and an approved lens cleaning solution. Avoid using paper towels, napkins, or the edge of your shirt, as these materials can contain abrasive fibers that cause micro-scratches.

4. Is nylon considered an eco-friendly lens material?

It is becoming an increasingly sustainable choice. Many leading brands now offer “bio-based nylon” lenses, which are derived from renewable resources like castor oil. This offers a significant environmental advantage over traditional petroleum-based plastics.

5. For a new eyewear brand, is starting with nylon a smart investment?

It depends entirely on your brand positioning. If you are launching as a premium, luxury, or high-performance brand, using nylon lenses from day one reinforces that message. If you are competing on value, polycarbonate is a more cost-effective starting point.