Custom Sunglasses with Logo: Methods, Costs, and Durability

Choosing a logo method involves balancing cost, durability, and aesthetics. Pad printing is cost-effective for promotions, while laser engraving offers permanent, premium marks. Methods like metal inlays provide a 3D finish. The right choice depends on your brand’s quality goals, frame material, and budget.

The Brand Manager’s Dilemma: Choosing a Method That Protects Your Brand

Why Most “Custom” Sunglasses Feel Cheap

The custom sunglasses market presents a significant challenge. You are faced with countless suppliers promising “custom” solutions, but the reality is that most offerings are generic, pre-made frames with a logo added as an afterthought. This creates a sea of sameness that makes it difficult to build a distinct brand.

Most Importantly: The market is flooded with low-quality promotional frames that are indistinguishable from one another, making it nearly impossible to create a memorable brand impression.

The Risk of Poor Logo Application

The consequences of choosing the wrong logo method go far beyond the initial cost. Printed designs are particularly susceptible to wear, and with frequent use, they may fade, peel, or scratch off. This degradation directly harms your brand’s reputation and can lead to customer complaints and negative reviews.

Critical Warning: A poorly executed logo can transform what should be a premium marketing tool into a liability that actively damages your brand perception.

The Fear of Wasting Your Budget

Your primary concern is investing in a product that fails to meet quality expectations. The fear is legitimate—choosing a customization method that looks cheap or fails prematurely can result in a significant financial loss. When customers receive sunglasses that feel flimsy and are quickly discarded, your brand message is lost.

The Goal: Balance Cost, Durability, and Prestige

This guide addresses your core challenge by providing a framework for evaluating logo application methods. You will learn to weigh cost-effectiveness, long-term durability, and brand image. This will empower you to match specific techniques to your unique requirements, from a high-volume promotional campaign to a premium product line.

The Essential Lexicon for Custom Eyewear

Understanding fundamental terminology is essential before exploring specific methods. This knowledge helps you communicate effectively with suppliers and make informed decisions about your project.

The Anatomy of a Sunglass

Your logo placement options include several strategic locations on a pair of sunglasses. The most popular spots are the outside temple, inside temple, and the lens. Each location offers different visibility and requires specific application techniques based on the surface material and shape.

The Levels of Customization

The customization landscape includes distinct service levels. OEM (Original Equipment Manufacturer) means creating a product from scratch based on your design. ODM (Original Design Manufacturer) involves choosing a pre-existing design from a factory’s catalog and customizing it. Understanding this helps you select the right service level for your brand.

The Language of Lenses

UV400 protection is the industry standard, blocking 99.9% of UVA and UVB rays. Polarized lenses reduce glare from reflective surfaces, making them valuable for driving and water sports. These technical specifications directly impact your product’s value and should influence your budget.

The Language of Production

Your manufacturer needs a vector file (AI, EPS, SVG) for a simple reason: infinite scalability. This means the file uses mathematical equations, not pixels, to build your logo. The benefit is that your logo remains perfectly sharp and clear, preventing the blurry, unprofessional look that comes from resizing a standard image file.

The 3 Core Families of Logo Application

Family 1: Additive Methods (Printing)

Additive methods involve applying materials like inks or foils onto the frame’s surface. These techniques offer excellent color flexibility and are generally the most cost-effective solution for large production runs, making them a popular choice for promotional products.

- Pad Printing: This technique uses a soft silicone pad to transfer ink from an etched plate onto the sunglass frame. Its unique advantage is the ability to print cleanly on curved or irregular surfaces, like the arm of a pair of sunglasses. It is the go-to for adding vibrant, multi-color logos.

- Screen Printing: This method pushes ink through a mesh stencil onto the frame. It works exceptionally well for bold, simple designs with large, solid color areas. It is less suited for fine details but provides excellent ink coverage on flat surfaces.

- UV Printing: This is a digital printing method that uses ultraviolet light to instantly cure ink as it’s applied. This technology allows for highly precise, full-color graphics and complex photographic designs to be printed directly onto frames without needing plates or screens.

The Bottom Line: Additive methods, especially pad printing, are built for vibrant, cost-effective logos at scale. They allow you to maximize brand visibility in high-volume campaigns where budget efficiency is the top priority.

Family 2: Subtractive Methods (Engraving)

Subtractive methods create logos by removing material from the frame surface. This approach creates permanent, durable markings that cannot fade, peel, or wear away under normal conditions, making them ideal for premium products where longevity is paramount.

- Laser Engraving: This process uses a high-precision laser to etch a design directly into the surface. The laser burns away a micro-layer of the material, creating a permanent mark. This technique offers unmatched precision for fine details, small text, and intricate logos.

- CNC Engraving: A computer-controlled machine uses a tiny rotating bit to carve the logo onto the frame. This method provides exceptional depth control and is particularly effective on metal frames where a substantial, carved-out effect is desired.

The Bottom Line: The core mission of subtractive methods is creating permanent and premium logos. An engraved design becomes part of the product itself, communicating a sense of quality and durability that aligns with high-end brand positioning.

Family 3: Applied & Inlaid Methods

Applied methods involve affixing a separate, physical logo element to the frame. These techniques create distinctive three-dimensional effects and a premium tactile feel that sets your product apart from standard printed or engraved designs.

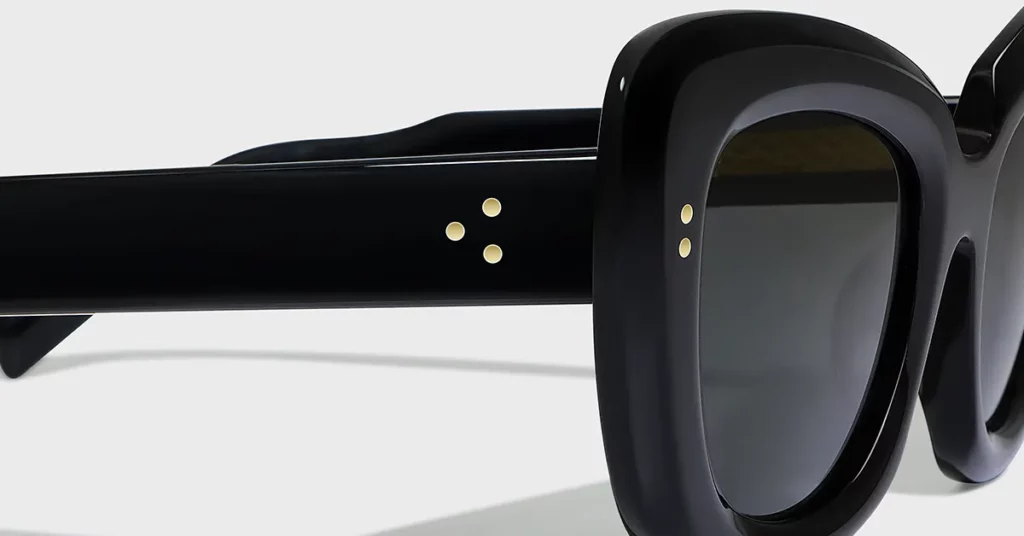

- Metal Logo Inlay: A small, custom-shaped piece of metal is embedded into a recessed area of the frame. This creates a sophisticated, flush-mounted logo that feels integrated and substantial, adding a touch of luxury.

- 3D Metal Transfer Sticker: This is a thin, metallic sticker made from nickel or chrome that adheres to the surface. It provides the premium look of a true metal inlay but without the high setup costs, making it a great option for startups or small runs.

- Epoxy Resin Inlay: An engraved area is filled with colored “crystal glue” and then polished smooth with the frame. This method creates a colorful and glossy logo with a sense of depth that catches the light beautifully.

- Hot Stamping (Foil Pressing): Heat and pressure are used to apply a metallic foil to the frame. This produces a brilliant, reflective metallic finish in gold, silver, or other colors, which strongly signals luxury and high fashion.

The Bottom Line: Applied methods are all about achieving a distinct, high-end 3D finish. These techniques add a tangible sense of quality that printing cannot match, justifying a higher price point for retail products.

The Decision Matrix: Choosing Your Method

Understanding how each method performs across key decision factors enables you to make a strategic choice that aligns with your project goals.

| Feature | Pad Printing | Laser Engraving | Metal Inlay | 3D Metal Sticker | Hot Stamping |

| Durability | Good | Permanent | Permanent | Excellent | Excellent |

| Unit Cost | $0.50 – $1.00 | $1.50 – $3.00 | $3.00 – $6.00 | $2.00 – $4.00 | $1.00 – $2.50 |

| Setup Fee | $40+ | $100+ | $200+ | None | $150+ |

| Visual Finish | Vibrant, Bold | Subtle, Premium | 3D Metallic | Premium 3D | Metallic Luxury |

| Best For | High-volume promotions | Corporate gifts, luxury | High-end retail | Startups, small runs | Fashion brands |

The Bottom Line: There is no single “best” method. Your choice should be a deliberate balance. Pad Printing wins for budget-driven volume. Laser Engraving is the champion for durability. Inlays and Hot Stamping deliver the most premium aesthetic for retail and fashion.

The Science of Selection: Matching Method to Material

Customizing Plastics: Promotional to Premium

Plastic frames offer the broadest range of customization options.

- Material: Standard Injected Plastic (PC, Polypropylene)

- Recommended Methods: Pad Printing, Screen Printing, UV Printing.

- Analysis: These printing methods adhere well to standard plastic surfaces and are perfectly aligned with the material’s cost-effective positioning. They provide the vibrant color needed for promotional items.

Common Mistake: Attempting to laser engrave very cheap plastic. Low-cost materials can melt or warp under the laser’s heat, resulting in a messy, unprofessional finish that damages your brand’s image.

Customizing Premium Acetate: The Artisan’s Choice

Cellulose acetate is a high-end, plant-based plastic known for its rich color depth and luxurious feel.

- Material: Cellulose Acetate

- Recommended Methods: Hot Stamping, Laser Engraving, Metal Inlays.

- Analysis: Acetate’s density and layered colors are ideal for methods that create depth. Hot stamping adheres beautifully to its smooth surface, and engraving can reveal contrasting color layers within the material for a stunning effect.

Pro Tip: For a truly high-end finish, combine a deep laser engraving with an epoxy fill. This creates a logo that is perfectly smooth to the touch, with a glossy, jewel-like appearance that communicates exceptional craftsmanship.

Customizing Metals: Sleek and Durable

Metal frames made from stainless steel or titanium signal durability and a minimalist aesthetic.

- Material: Stainless Steel, Titanium, Aluminum

- Recommended Method: Laser Engraving.

- Analysis: For metal frames, laser engraving is the most suitable option. It provides the cleanest, most permanent mark possible. The laser’s precision creates sharp, professional results that complement the sleek, high-tech nature of metal eyewear.

Customizing Natural Materials: Wood & Bamboo

Natural materials like wood and bamboo require a technique that enhances, rather than covers, their organic beauty.

- Material: Wood, Bamboo

- Recommended Method: Laser Engraving.

- Analysis: Laser engraving is the most popular way to add a logo to wood because it enhances the natural aesthetic. The process burns the logo into the wood, creating a subtle, rustic effect that feels authentic and avoids the use of inks or chemicals.

Leveling Up: Beyond Promotional Logos

The “Logo Slap”: Branding Pre-Made Frames

This common approach involves selecting a generic, “open-mold” frame from a supplier’s catalog and simply adding your logo.

- The Pros: This method is defined by its low cost, fast turnaround, and low minimum order quantities (MOQs), often starting around 50 pieces. It’s an accessible entry point for branded merchandise.

- The Cons: Your product is not unique and offers very limited brand differentiation. You run the risk of your product being identical to a competitor’s, except for the logo.

The “True Custom” Partnership: OEM/ODM

For premium brands, creating a unique product is essential for building long-term value.

- Definition: An OEM (Original Equipment Manufacturer) partnership means creating a unique frame design that is proprietary to your brand. This involves creating custom molds and gives you deep control over the final product.

- The Strategic Value: This process creates a unique, defensible product that is 100% your own. It is an investment in building real brand equity and allows you to craft sunglasses that perfectly align with your brand identity.

Quality Control: How to Spot a Quality Job

Hallmarks of a High-Quality Logo

- For Engraving: Look for crisp, clean edges with no “burn” marks or discoloration.

- For Printing: Demand perfect registration (no color bleeding), sharp lines, and complete color opacity.

- For Inlays & Stickers: The logo must be perfectly flush with the frame surface, with no visible gaps or adhesive.

- For All Methods: Check for perfect alignment and consistent placement across every unit in your order.

Common Production Red Flags

- Misaligned or Crooked Logos: This indicates poor tooling or a lack of process control.

- Inconsistent Ink Color: Variations between units suggest a supplier has poor quality control over their ink mixing.

- Peeling or Flaking: A logo that fails a simple friction test will not survive in the real world.

- “Wobbly” Metal Logos: A poorly seated metal logo indicates weak bonding and will eventually fall out.

Actionable Tip: Use the “Fingernail Test” to check adhesion. Gently run your fingernail along the edge of a printed or applied logo. It should not lift or peel in any way. A quality application feels completely bonded to the surface.

Questions to Ask Your Supplier

- “What are your QC tolerance standards for logo placement and alignment?”

- “What durability tests do you perform, like adhesion or sweat tests?”

- “Can you provide production-grade samples for our approval before we commit to the full order?”

- “Are your frames compliant with the ISO 12870:2016 eyewear standard?”

Conclusion

Understanding your options empowers you to make confident decisions. For speed and volume, pad printing is the go-to for promotional needs. For ultimate durability and a premium feel, laser engraving is unmatched. For a distinct retail look, metal inlays and hot stamping offer superior visual value. And for startups, 3D metal stickers provide a premium look with no MOQ. Always vet your supplier and demand production-grade samples to ensure your final product perfectly represents your brand’s quality standards.

Frequently Asked Questions

1. What is the most durable method for putting a logo on sunglasses?

When it comes to durability, laser engraving takes the lead. The engraved design becomes a permanent part of the product, making it resistant to fading, scratching, or rubbing off. It physically alters the frame material, ensuring the mark lasts for the life of the sunglasses.

2. How much does it cost to get logos on sunglasses?

Costs vary greatly. Simple pad printing can be $0.50-$1.00 per unit plus a setup fee, while premium metal inlays can cost $3.00-$6.00 per unit with a higher initial tooling cost. Always factor in both the per-piece price and any one-time setup fees to understand the true total cost.

3. Can you put a logo on the lens of the sunglasses?

Yes, a logo can be placed on the lens. This is typically done with a subtle laser etch or a semi-transparent print. The key is to position it in a corner where it does not obstruct the wearer’s vision, creating a unique branding statement.

4. What file format do I need to provide for my logo?

You should always provide a vector file, such as an AI (Adobe Illustrator), EPS, or SVG. These formats use mathematical formulas instead of pixels, which means your logo can be scaled to any size without losing its sharpness, ensuring a crisp, professional result.

5. What is the typical minimum order quantity (MOQ) for custom sunglasses?

MOQs depend on the method. Promotional pad printing often requires 100-300 units. True custom OEM manufacturing can start at 500-1200 units. A great exception is 3D metal stickers, which often have no MOQ, making them ideal for small brands.