The Difference Between Pure and Beta Titanium Frames

Pure titanium offers the highest corrosion resistance and is 100% nickel-free, making it ideal for classic, robust, and hypoallergenic frames. Beta titanium is a flexible alloy with superior durability and shape memory, allowing for thinner, more minimalist designs. The choice depends on prioritizing ultimate purity versus design flexibility for a frame’s specific purpose.

Titanium 101: The Foundation of Premium Eyewear

Before you can choose between them, you need to understand what makes titanium the gold standard in premium eyewear. The term “titanium” isn’t a single thing; it refers to a family of materials, each with unique properties. Your job is to pick the right family member for the task at hand.

What Is “Titanium” in Eyewear?

When we talk about pure titanium, we are referring to a metal that is over 99% titanium. This means it is almost entirely the single element, with only trace amounts of others. This purity is its defining feature, making it the ultimate choice when biocompatibility is your top priority.

In contrast, beta titanium is a titanium alloy. This means it’s a “recipe” where other metals like vanadium, chromium, or aluminum are intentionally mixed in with the titanium. Think of it like the difference between pure 24k gold and 18k gold—adding other elements to the mix creates a material with higher hardness and entirely new capabilities.

Pro Tip: Always demand material specification sheets from your manufacturer. This document is your proof of the exact titanium grade and composition you are buying, protecting your brand from any quality issues down the line.

The Core Value: Why Premium Brands Use Titanium

Both pure and beta titanium share a set of incredible benefits that make them ideal for premium frames. Understanding these universal properties helps you communicate value to your customers and justify a higher price point.

- It Is Hypoallergenic: The complete absence of nickel makes titanium biocompatible. This means it won’t react with the skin, making it the safest and most comfortable option for customers with metal sensitivities.

- It Resists Corrosion: Titanium is incredibly resistant to corrosion from sweat, humidity, or salt in the air. This ensures the frames maintain their structural integrity and pristine appearance for years, even with daily, active use.

- It Is Strong Yet Lightweight: A frame made from titanium is about 48% lighter than one made from traditional metals like monel, but with far superior strength. This exceptional strength-to-weight ratio allows for delicate, thin designs that remain incredibly durable.

Best Practice: These three benefits are your core consumer-facing selling points. Focus on hypoallergenic properties for sensitive customers, corrosion resistance for active lifestyles, and lightweight comfort for anyone who wears glasses all day.

Deep Dive: The Profile of Pure Titanium (99% Purity)

Pure titanium is the foundational material. It represents the most elemental form of this remarkable metal, offering unmatched purity and performance characteristics that make it perfect for specific applications.

What “Pure” Titanium Really Is

The designation “pure” means the material consists of 99% or more titanium. The remaining fraction is just trace elements, not intentionally added alloys. Simple Analogy: Just as pure water is simply H₂O without additives, pure titanium is the element in its unadulterated state. This is why it’s often designated as CP, or “Commercially Pure,” in grades from 1 to 4.

Remember This: This high level of purity is the source of its completely hypoallergenic quality. When a customer has severe metal allergies, specifying pure titanium is the safest and most reliable choice you can make.

Key Benefit: Unmatched Rigidity

The defining characteristic of pure titanium is its structural rigidity. It holds its intended shape with incredible precision and resists bending or deforming from daily use. Think of it like the steel I-beam in a skyscraper—it provides unwavering structure without adding unnecessary bulk or weight.

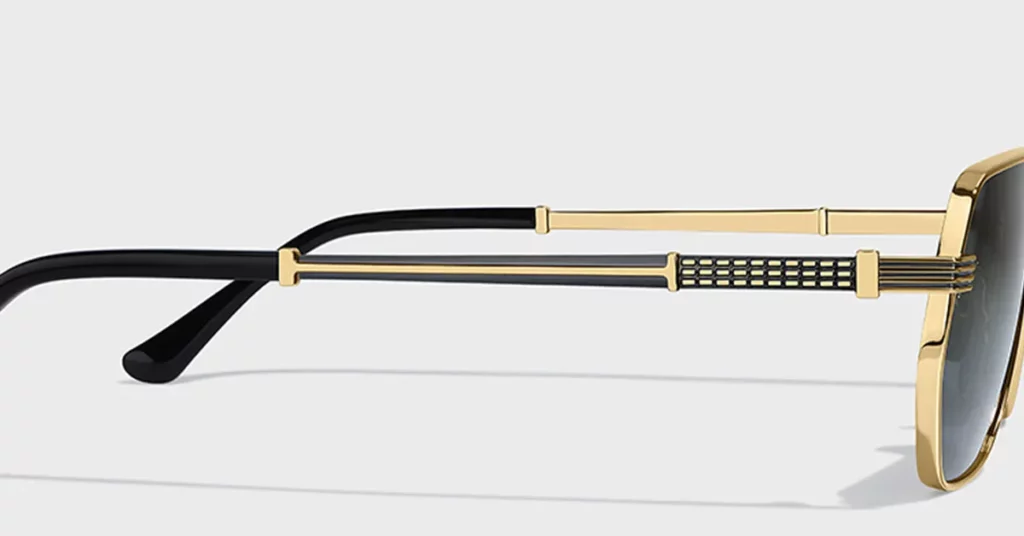

For Example: This material is perfect for creating the kind of precise, architectural styles you see from brands like Lindberg, where crisp lines and exact angles define the entire design aesthetic. When your design requires sharp, unwavering geometry, pure titanium is the answer.

Key Trade-Off: Its Relative Softness

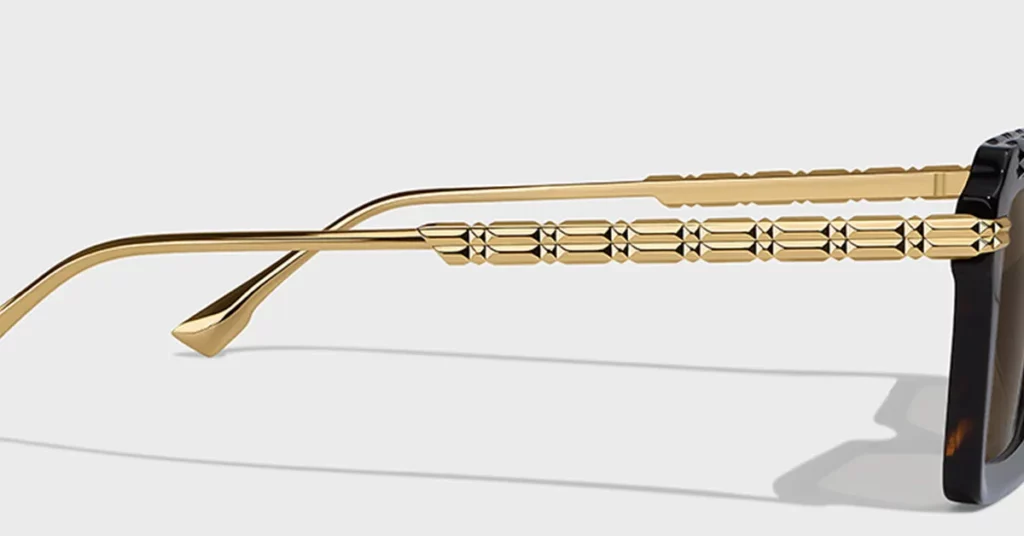

While pure titanium is rigid, you must understand that the metal itself is relatively soft. This creates a paradox: the frame resists bending, but its surface can be more easily marked or scratched compared to harder alloys. This softness, however, also makes it ideal for highly detailed surface work.

Common Mistake: Don’t confuse rigidity with hardness. A material can be very rigid (resists bending) but still have a soft surface (susceptible to scratches). Understanding this distinction is key to choosing the right material.

Pro Tip: To get the best of both worlds, use advanced coatings like Physical Vapor Deposition (PVD) or Ion Plating (IP). These treatments add a hard, protective layer to the surface, enhancing scratch resistance while preserving the frame’s underlying purity and rigidity.

Manufacturing: The Welding Challenge

You need to know that welding titanium is notoriously difficult. The process must happen in a completely controlled, oxygen-free environment. This is because at high temperatures, titanium reacts instantly with oxygen, creating brittle compounds that dramatically weaken the welded joint.

Critical Warning: Improper welds are a primary point of structural failure in titanium frames. The bridge and temple hinge joints are the highest-stress areas, and a poor weld here will almost certainly lead to a broken frame and an unhappy customer.

Deep Dive: The Profile of Beta Titanium (The Alloy)

Beta titanium is an engineered material. Specific alloying elements are added to the titanium base to create enhanced flexibility and performance characteristics that are impossible to achieve with the pure metal alone.

What “Beta” Titanium Really Is

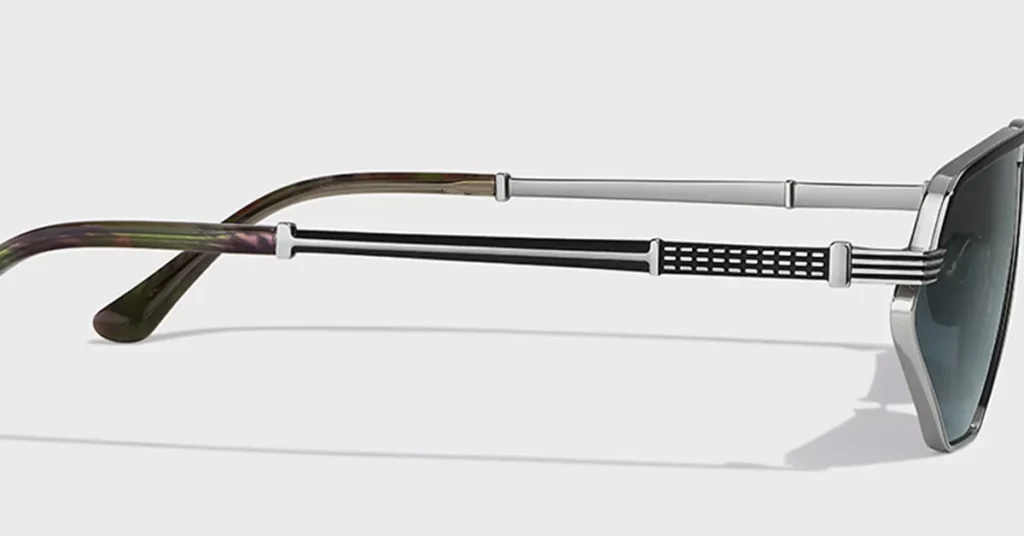

Beta titanium is an alloy containing titanium plus other elements like vanadium and aluminum. These added metals fundamentally alter the material’s crystal structure, creating its signature properties. Simple Analogy: Think of it as “performance-tuned” titanium, like adding carbon fiber to a car’s chassis. The base is enhanced to achieve superior flexibility and durability.

Definition: The specific recipe of alloying agents dictates the final properties. Advanced formulations can include a precise balance of elements like Molybdenum and Zirconium to achieve very specific performance targets for flexibility and strength.

Key Benefit: Superior Flexibility

The signature benefit of beta titanium is its remarkable shape memory. This means you can bend or twist the material significantly, and it will return to its original form without damage. This property comes from the alloy’s unique crystal structure, which allows for reversible deformation.

For Example: This makes beta titanium the perfect material for durable children’s eyewear or performance sports frames that need to withstand rough handling. Its ability to flex under pressure makes it nearly indestructible under normal use conditions.

Key Trade-Off: Hardness vs. Rigidity

The alloying process makes beta titanium a significantly harder material than pure titanium. This means it’s much more resistant to surface scratches and dings from daily wear. However, this hardness makes achieving fine, detailed engraving more difficult and costly.

Remember This: The flexibility that gives beta titanium its durability also makes it unsuitable for designs that demand sharp, unwavering lines. You trade the architectural precision of pure titanium for the dynamic resilience of an alloy.

Pro Tip: This material is perfect for creating ultra-thin temple arms that need to flex and grip the head comfortably. The flexibility allows for a secure, snug fit without creating painful pressure points.

Manufacturing: Coloring and Finishing

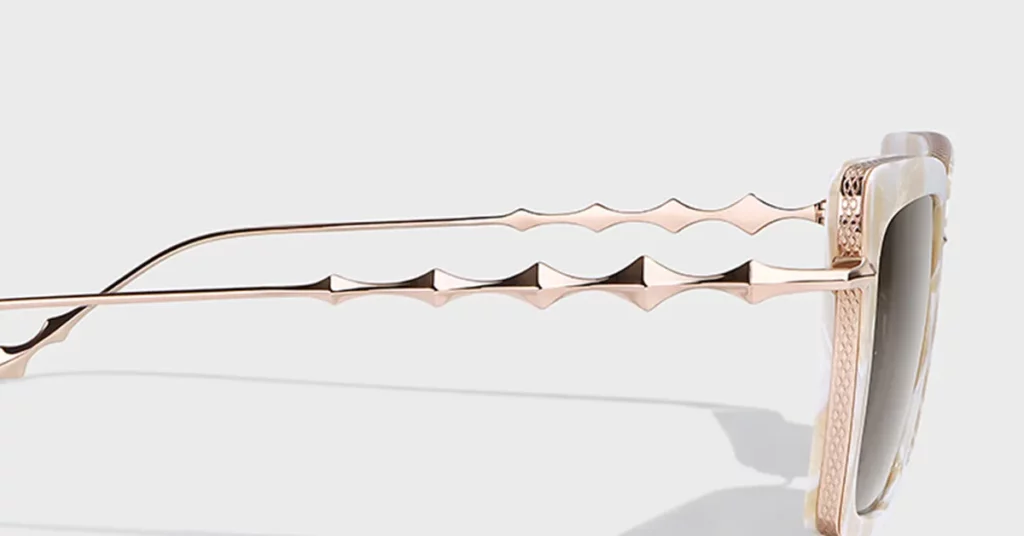

The presence of other metals in a beta titanium alloy can influence how it responds to certain color treatments. For anodizing, the alloying agents can sometimes limit the vibrancy or consistency of the final color.

The Bottom Line: For the widest and most vivid range of anodized colors, pure titanium is the superior choice. Its chemical purity allows for more consistent and brilliant results. However, beta titanium’s hard surface provides an excellent base for durable paint and PVD coatings.

The B2B Decision Matrix: Matching Titanium to Your Brand

Learning to systematically evaluate materials transforms you from a designer who simply follows specs into a strategic partner who makes recommendations that drive business goals. Focus on these steps to justify your choice.

- Define the Core Function: Start with the product’s single most important need. Is it extreme durability for kids’ frames or precise rigidity for a luxury design?

- Define the Brand Position: Your material must support your brand story. Is your brand about artisanal luxury, technical performance, or minimalist elegance?

- Align Material with Both: The best choice is the one that perfectly aligns the functional need with the brand promise, creating a cohesive and powerful product story.

| Feature | Pure Titanium (The Purist) | Beta Titanium (The Performer) |

| Flexibility | Rigid; holds its shape precisely | Highly flexible with shape memory |

| Surface Hardness | Softer surface, easier to engrave | Harder surface, more scratch-resistant |

| Weight | Ultra-lightweight | Extremely lightweight (nearly identical) |

| Welding | Requires a highly controlled process | More forgiving welding process |

| Anodized Color | Excellent for vibrant, consistent colors | Color range can be more limited |

| Ideal Design | Architectural frames with sharp lines | Thin, minimalist, or flexible frames |

The Bottom Line: The choice is a strategic trade-off. You are choosing between the absolute purity and rigidity of pure titanium versus the engineered flexibility and durability of beta titanium. Neither is better; they are different tools for different jobs.

Strategic Scenario 1: A Minimalist Luxury Brand

When your brand story is built on purity, precision, and timelessness, pure titanium is the clear choice.

- Analysis: Pure titanium’s rigidity is essential for maintaining the crisp, unwavering lines that define a high-end minimalist aesthetic.

- Application: Use pure titanium for the frame front to hold the lens shape perfectly, ensuring the geometric integrity of the design never falters.

- Justification: The 99%+ purity aligns with a brand story of uncompromising quality, while its rigidity backs up claims of lasting precision and architectural beauty.

Strategic Scenario 2: A Performance Sports Eyewear Line

When your brand serves active customers who demand comfort and extreme durability, beta titanium’s flexibility is the winning feature.

- Analysis: The shape memory and impact resistance of beta titanium are non-negotiable for customers who will subject their frames to stress.

- Application: Use beta titanium for the temple arms and bridge to provide maximum resilience where frames are most likely to bend or break.

- Justification: The engineered alloy supports a brand story of advanced technology and innovation, while its durability provides the real-world performance your customers demand.

Real-World Insights: Failures, Myths & Best Practices

Understanding the real-world limits and failure points of these materials helps you design better products and build trust with your customers.

Myth vs. Fact: Is It Unbreakable?

There is a common myth that beta titanium frames are “unbreakable.” While incredibly resilient, you must set correct expectations.

- The Myth: You can bend or twist it in any direction without consequence.

- The Fact: All materials have a fatigue limit. Even beta titanium can fail if subjected to repeated, extreme bending over a long period.

- Simple Analogy: It’s like a paperclip. You can bend it back and forth many times, but it’s not infinite. Eventually, the metal will fatigue and break.

Pro Tip: Position the material as “highly resilient” and “shape-recovering” in your marketing. This is an honest and accurate description that builds long-term trust and avoids future warranty claims from disappointed customers.

Failure Points: Why Frames Break

Even the best materials can fail if not manufactured correctly. Always look for these common weak points.

- The Weld Point: The weld at the bridge or temple is the most common point of failure. This is almost always caused by microscopic oxygen contamination during the welding process, which makes the joint brittle.

- The Material Junction: Another weak spot is where two different materials meet, such as where a flexible temple arm joins a solid hinge piece. This transition creates a stress concentration that can lead to failure.

Best Practice: Work with manufacturers who can demonstrate their expertise in oxygen-free welding. For ultimate durability, consider a “mono-block” design that uses a continuous piece of beta titanium for the temple and hinge, eliminating the weak junction point entirely.

Best Practices: Care and Maintenance

Proper care extends the life of the frame and protects your brand’s reputation. Advise your customers to follow these simple rules.

- Rinse Regularly: Always rinse off saltwater, sweat, and chemicals with fresh water to prevent any long-term buildup that could affect coatings.

- Clean Gently: The best method is the simplest. Use a solution of mild dish soap and lukewarm water, then dry with a clean, soft microfiber cloth.

- Inspect Often: Encourage users to regularly check weld points and hinge screws. Catching a small issue early can prevent a sudden and catastrophic frame failure.

Critical Warning: Be cautious with ultrasonic cleaners. While effective, their powerful vibrations can sometimes loosen hinge screws or damage delicate lens coatings over time.

Conclusion

The choice between pure and beta titanium isn’t about which is “better,” but which is the right tool for your specific design and brand goals. Pure titanium delivers unmatched purity and rigidity for architectural designs, while beta titanium offers superior flexibility and resilience for performance applications. By aligning your material choice with both your product’s function and your brand’s story, you can create eyewear that performs flawlessly and resonates with your target customer.

For a more advanced analysis of material selection strategies and supply chain considerations, explore our comprehensive A Manufacturer’s Framework for Strategic Eyewear Material Selection.

Frequently Asked Questions

1. Which material is more forgiving for a new designer?

Beta titanium is generally more forgiving for new designers. Its inherent flexibility can compensate for minor stress points in a design, whereas pure titanium’s rigidity requires more precise engineering to avoid weak spots.

2. Is there a big price difference between pure and beta titanium?

Yes, pure titanium frames are typically more expensive. This is not just due to material purity but also the more complex and difficult manufacturing process, especially the highly controlled welding required to ensure durability.

3. Can a broken titanium frame be repaired?

It is very difficult. Most opticians cannot repair a broken titanium weld. A specialized jeweler with a laser welder is often the only option, making repairs both challenging and expensive for the customer.

4. What makes premium titanium frames so expensive?

The high cost is driven primarily by the complex manufacturing process. Welding titanium in a vacuum environment requires specialized equipment and expertise. This processing and tooling cost is a much larger factor than the raw material expense itself.

5. Can you be allergic to beta titanium?

It’s highly unlikely. Reputable manufacturers use nickel-free alloys for beta titanium, making it hypoallergenic. However, pure titanium remains the only option that is guaranteed to be 100% free of any potential allergens.