The Founder’s Guide to Eyewear QC: A Step-by-Step Framework to Ensure Product Quality

Eyewear quality control is a step-by-step inspection process to find and fix defects during manufacturing. It involves physically checking frames, testing lenses, and verifying materials against an approved “Golden Sample.” This prevents catastrophic financial loss and protects your brand’s reputation by ensuring product quality before shipment.

Why QC is Your Brand’s Ultimate Insurance Policy

You need to see quality control as the single greatest lever you have for building a successful brand. Too many founders view QC as just another expense. In my two decades of teaching designers, I’ve consistently observed that this is a mistake. In reality, it is the foundational investment that protects your capital and ensures your brand can thrive in a competitive market.

Defining the Core Concepts for New Founders

Before you can manage a quality control process, you must first understand the two distinct concepts that work together to protect your product: Quality Control and Quality Assurance.

You need to understand that Quality Control (QC) is the hands-on process of inspecting your product to find defects. This means your team is physically examining frames for scratches, testing hinge functionality, and using specialized tools to verify that colors match your specifications. It is the active search for problems at key stages of production.

You must also understand Quality Assurance (QA), which is the high-level strategy your factory uses to prevent defects from ever occurring. This means it’s not about inspection, but about the entire system of production—from worker training and equipment maintenance to documented procedures. Think of it like a chef creating a meticulously clean and organized kitchen before they even start cooking; it’s the professional setup that makes a quality outcome possible.

Simple Analogy: Think of QA as the healthy diet and exercise plan that keeps you well, while QC is the regular doctor’s check-up that catches any specific health issues. Both are essential for long-term health, just as both QA and QC are critical for product quality.

Definition: A “Golden Sample” is the single, perfect product prototype that you formally approve. This sample then becomes the non-negotiable benchmark for your entire production run. It locks in your exact standards for color, materials, and finish, giving your inspectors an objective reference to compare against every other unit.

Pro Tip: Always keep at least three Golden Samples: one for the factory floor, one for your third-party inspection team, and one for your own office. This creates essential redundancy and ensures everyone is working from the same standard.

The High Cost of Failure: Real-World Risks of Skipping QC

Ignoring proper quality control has consequences that go far beyond a few customer complaints. In a world driven by online reviews, a single quality failure can permanently damage your brand before you even have a chance to get started.

| Risk Category | Specific Failure Example | The Business Impact |

| Financial Loss | An entire shipment arrives with mismatched colors or weak hinges. | You face a 100% loss on your investment, having paid for thousands of units that are completely unsellable. |

| Reputation Damage | The first batch of products generates dozens of negative online reviews. | Your new brand is immediately labeled as “cheap” or “low-quality,” creating a negative perception that is nearly impossible to reverse. |

| Legal Liability | Frames are found to contain banned chemicals like lead or fail impact tests. | You face mandatory product recalls, regulatory fines, and potential lawsuits, which can lead to your products being banned from sale. |

Most Importantly: Every dollar you invest in a proper quality control process will save you an estimated ten dollars in potential losses from defective products, customer returns, and irreversible brand damage. Effective QC is the single greatest lever you have to de-risk your investment.

Step 1: Incoming Quality Control (IQC)

The most effective QC happens before production even begins. This first stage, Incoming Quality Control (IQC), is about verifying all raw materials and components. This step prevents flawed materials from compromising your entire production run right from the start.

The Business Problem: Color Mismatches in Acetate

The Step: Verifying Raw Acetate Color.

The Action: Before any material is cut, your QC team must compare the raw acetate sheets directly against your approved Golden Sample and Pantone standard. This check must happen in the materials receiving area of the factory.

The Rationale: This prevents the most common eyewear defect—color inconsistency. It ensures the vibrant “Tokyo Tortoise” you specified doesn’t become a dull, unsellable brown, solving the problem at the source for almost no cost.

The Technical Check: A spectrophotometer provides an objective, numerical value for color, removing any subjective judgment. This instrument measures the light reflected by the material to ensure it matches your specifications with scientific precision.

Remember This: A digital color file on a screen is not a reliable standard. Always provide your manufacturer with physical color standards, like a Pantone swatch or a piece of your Golden Sample, to ensure perfect color matching.

The Business Problem: Frames with Unsafe Chemicals

The Step: Verifying Material Chemical Safety.

The Action: You must formally request lab test reports and certifications for all restricted substances. This includes checks for lead, cadmium, and nickel release, which are common issues in metal frames.

The Rationale: This protects your business from devastating outcomes like having your entire shipment seized by customs or, worse, causing skin irritation for your customers. It ensures your product is legally compliant and safe for sale in your target markets.

The Technical Check: You must review supplier reports for compliance with key regulations like REACH (for Europe) or Prop 65 (for California). Different markets have different rules, and it is your responsibility to ensure your product meets them all.

Critical Warning: Chemical testing is not instant; it often takes 7-14 days to get complete results back from a lab. You must build this timeline into your production schedule and never skip chemical verification to save time.

Step 2: In-Process Quality Control (IPQC)

In-Process Quality Control (IPQC) involves inspecting products as they are being manufactured. This allows you to catch and correct problems on the assembly line, which is far more efficient than finding them in thousands of finished units.

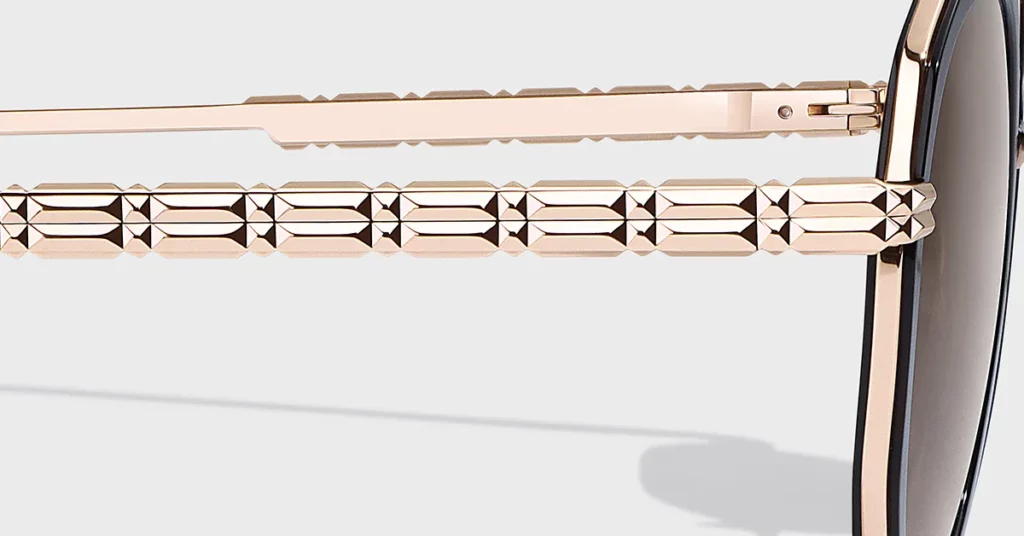

The Business Problem: Cheap-Looking Welds on Metal Frames

The Step: Inspecting Welded Joints.

The Action: Inspectors must check welding points for smoothness, consistent color, and strength immediately after the joint is created. The check should involve both visual and manual stress tests.

The Rationale: This directly impacts the perceived value and durability of your frames. Good welds are nearly invisible and strong, while poor welds look rough and can break easily. This check is a key differentiator between low- and high-quality metal eyewear.

The Business Problem: Inconsistent Acetate Polishing

The Step: Checking Polishing and Finishing Consistency.

The Action: Inspectors compare the gloss level and surface smoothness of frames coming out of polishing against the “Golden Sample” under controlled lighting. This checks both the automated tumbling and the final hand-polishing stages.

The Rationale: The surface finish creates the customer’s first impression of quality. This check ensures every frame has the same lustrous, premium feel, preventing a mix of glossy and dull frames in your inventory.

Simple Analogy: Proper polishing on an acetate frame is like the final clear coat on a luxury car. It’s the last step that creates the deep, flawless shine that signals premium quality to the buyer.

The Kssmi Visual Defect Library

Visual inspection is your most powerful and immediate QC tool. Knowing how to spot common flaws allows you to communicate effectively with your factory. Below are common pass/fail examples.

Frame Fronts & Rims

| Pass Example | Fail Example |

| Smooth, even polishing with no visible scratches. | Visible glue residue where the end piece meets the rim. |

| Consistent color and material clarity. | Bubbles or streaks within the acetate material itself. |

| Lens fits snugly and securely in the rim. | A visible gap between the lens and the rim, indicating a poor fit. |

Temples & Hinges

| Pass Example | Fail Example |

| Temples are symmetrical and level on a flat surface. | A “lazy” spring hinge that doesn’t snap back crisply into place. |

| Hinge area is clean and free of marks. | Scratches or tool marks on the hinge from improper assembly. |

| Temple tips are aligned perfectly with the temple arms. | Misaligned temple tips that are not flush with the temple arm. |

Pro Tip: Ask potential manufacturing partners for photos of their common defects and how they classify them (e.g., Minor, Major, Critical). A factory that is transparent about its flaws is demonstrating a genuine commitment to quality.

Step 3: Final Assembly & Workmanship Inspection

This stage is your last chance to inspect individual components and their functionality before the product is placed in its packaging. It focuses on how all the parts work together as a whole.

The Business Problem: Weak or Misaligned Hinges

The Step: Hinge Function and Endurance Testing.

The Action: The QC Solution is a two-part inspection of the hinge mechanism on fully assembled frames. First, you perform a functional check to ensure the opening and closing tension is smooth and consistent. Second, you conduct an endurance test, where a machine opens and closes the temples hundreds of times.

The Rationale: This matters because it simulates long-term use, revealing weaknesses that would otherwise only appear after a customer has been using the product for weeks. It prevents complaints about temples feeling “too loose” or “too tight.”

Best Practice: Do not leave hinge selection to your factory. Your tech pack should specify the exact hinge type (e.g., 5-barrel) and even the screw type (e.g., self-locking) to ensure premium durability.

The Business Problem: Lenses That Distort Vision or Fall Out

The Step: Lens Fit and Optical Distortion Check.

The Action: Inspectors verify that lenses are mounted securely without being overly stressed. They then use a polariscope to check for stress points around the edge of the lens.

The Rationale: An improperly mounted lens can create optical distortion, leading to customer headaches and complaints. The polariscope reveals this hidden stress, which is invisible to the naked eye but has a major impact on visual comfort.

The Business Problem: Asymmetrical Frames That Sit Crooked

The Step: The “Flat Surface” Symmetry Check.

The Action: An inspector simply places the glasses upside down on a flat table with the temples open. To pass, both temple tips must touch the surface evenly without any rocking.

The Rationale: This simple, five-second test instantly verifies the frame’s fundamental geometric balance. A failed test means the frame will sit crooked on a customer’s face, which is an immediate and obvious quality failure.

Step 4: The Pre-Shipment Inspection (PSI)

The Pre-Shipment Inspection (PSI) is your final go/no-go decision point. It is a comprehensive audit of a portion of your fully packaged order, conducted before the goods leave the factory and before you make your final payment.

The Business Problem: A Perfect Sample, A Flawed Shipment

The Step: Final Random Inspection.

The Action: The QC Solution is to conduct a Pre-Shipment Inspection (PSI) on a random, statistically significant sample of your fully packaged order. The Action is to use an industry-standard AQL (Acceptable Quality Limit) framework to get a reliable snapshot of the entire batch’s quality.

The Rationale: This provides an unbiased, data-driven basis for your final go/no-go decision, protecting you from approving a shipment based on a few unrepresentative “perfect” samples. It’s the only way to know the true quality of the bulk order.

Definition: AQL 2.5 is a common standard in eyewear. It means you are willing to accept the entire shipment if a statistical sampling finds no more than 2.5% of the units have major defects. For critical defects, the AQL is always 0, meaning zero tolerance.

Best Practice: Even if you have a great relationship with your factory, always use a third-party inspection service for the PSI. This ensures you receive a completely objective and unbiased report that is focused solely on protecting your interests.

Beyond the Naked Eye: Key Lab Performance Tests

Certain critical performance attributes can only be verified in a laboratory. These tests are often mandatory for legal compliance in your target market.

| Test Name | Purpose | Why It Matters for Your Business |

| Drop Ball Test | Measures lens impact resistance. | This is mandatory for the US market under FDA regulations. Failure can get your shipment seized by customs. |

| UV Protection Test | Verifies that lenses provide UV400 protection. | Ensures your product delivers on its advertised functional claims and protects your customers’ eye health. |

| Corrosion Resistance | Simulates exposure to sweat and moisture (salt spray test). | Verifies that metal frames and coatings will not corrode or degrade under normal long-term wear conditions. |

Remember This: Always request and file copies of all lab test reports. This documentation is your proof of due diligence and can be requested at any time by retailers or regulatory agencies.

The Founder’s Toolkit: How to Vet a Manufacturing Partner

Your choice of a factory is the single most important decision you will make. A great partner makes quality easy; a poor one makes it impossible. Use these questions to assess their true commitment to quality.

Questions About Their Quality System

- “Can you please provide your ISO 9001 certification?” (Tests for a formal, audited quality system).

- “Can you walk me through your QC process, from raw materials to final packaging?” (Tests for a comprehensive approach).

- “How do you train your inspectors on our specific product’s quality standards?” (Tests for process control).

- “What is your formal process when a major defect is found during production?” (Tests their problem-solving ability).

Questions About Sourcing & Transparency

- “Who are your primary suppliers for key components like acetate and hinges?” (Tests their supply chain quality).

- “Am I allowed to have my own third-party inspector on-site for a PSI?” (A “no” is a major red flag).

- “How do you ensure that rejected units are destroyed and not mixed back into my order?” (Tests their integrity).

Conclusion

Mastering this quality control framework is what transforms you from a hopeful founder into a confident brand builder. You do not need to be a manufacturing expert, but you must be an expert on your own quality standard. By implementing these steps, you build a brand that delights customers, earns their trust, and stands the test of time, all while protecting your critical initial investment.

Frequently Asked Questions

1. Can I just rely on my factory’s internal QC team?

While a factory’s internal team is a good first line of defense, they have an inherent conflict of interest. Always use an independent third-party inspector for the final Pre-Shipment Inspection to get an unbiased, objective report that protects your interests.

2. How much does a third-party inspection typically cost?

A third-party inspection typically costs between $200 and $400 for a full day’s work. This is a tiny fraction of your total product cost and provides an outstanding return on investment by preventing you from accepting a shipment of defective goods.

3. What is the most common point of failure in eyewear manufacturing?

In my experience, the two most frequent quality issues are color consistency in acetate and the functional durability of hinges. Both problems can almost always be traced back to a failure to perform proper Incoming Quality Control (IQC) on raw materials.

4. How do I create my first QC checklist if I’m not technical?

Start by using your Golden Sample as the primary reference. List out its key attributes: color, finish, hinge feel, and weight. You can then work with an experienced inspection company to help you add more technical checkpoints specific to your design.

5. What do I do if my shipment fails its Pre-Shipment Inspection?

If an inspection fails, you should immediately contact your manufacturer with the detailed report. Your options typically include having the factory rework the defective units, negotiating a discount, or, in severe cases, rejecting the entire order.