Mirrored Sunglasses Benefits: Glare, UV, Clarity

Mirrored sunglasses have a reflective coating on the lens exterior that reduces the amount of light passing through to your eyes. This metallic layer, applied via vacuum deposition, can decrease light transmission by an additional 10% to 60%, making it ideal for extremely bright conditions where standard tints fall short.

The Anatomy of a Mirrored Lens

What is a Mirror Coating?

A mirror coating is a microscopic metallic layer applied to the outer surface of a lens. Its main job is to reflect a portion of incoming light away from your eyes before it can pass through the lens material. This makes it a powerful tool for managing bright and high-glare environments.

Simple Analogy: Think of the coating exactly like a one-way mirror. From the outside, people see their own reflection, but from your perspective, you maintain clear vision looking out. This provides both visual comfort and privacy.

A point that often confuses new designers is that the mirror coating is a separate treatment applied over an existing lens color. You start with a base tint like gray or brown, and then the mirror is added as a distinct layer. This means you can create nearly any combination of base tint and mirror color your brand requires.

Most Importantly: The base tint determines the color of the world you see through the lens. The mirror coating determines the color and look that other people see when they look at you.

The Impact of Light Reduction

The practical effect of a mirror coating goes far beyond style. A mirror can reduce the amount of light that reaches your eye by an additional 10% to 60% compared to a non-mirrored lens. This is a substantial reduction that makes a real difference in comfort and performance.

For Example: The same technology that protects astronauts’ eyes from unfiltered solar radiation in space is used in your sunglasses. NASA first developed this reflective coating for helmet visors, using the same scientific principles to reflect harmful light.

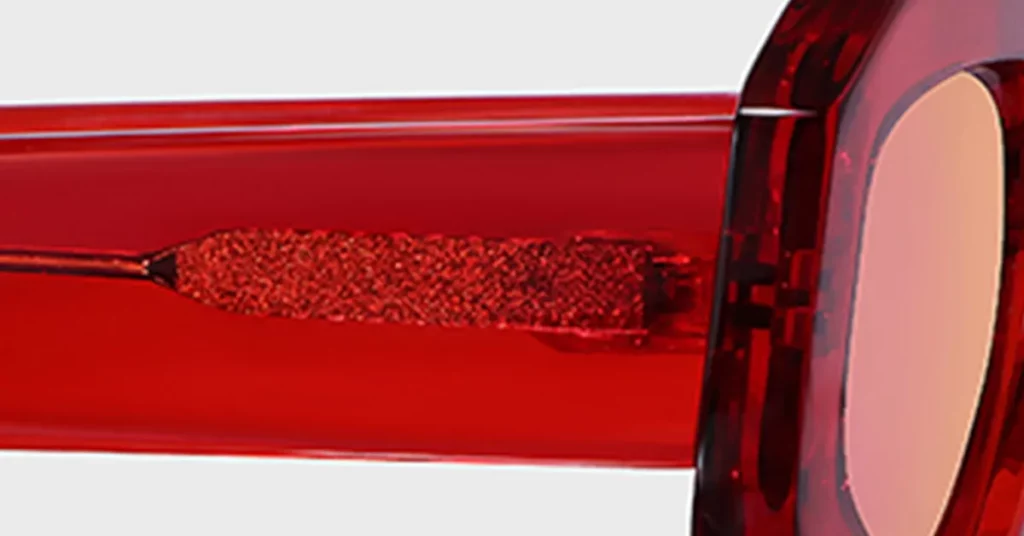

A Visual Glossary of Mirror Types

Type 1: Solid Mirror

A solid mirror, also known as a full mirror, creates a dense, completely reflective surface on the lens. This coating transforms the lens into what looks like a genuine mirror from the outside, offering the boldest aesthetic and the highest level of light reduction.

The key feature of a solid mirror is its opacity. It completely conceals the wearer’s eyes, offering maximum privacy. This makes it a popular choice for law enforcement and anyone seeking an assertive, confident style.

Best Practice: Use solid mirrors for the brightest conditions where you need maximum glare reduction. They are perfect for water sports, skiing, and desert environments where reflected sunlight can be intense.

Type 2: Flash Mirror

A flash mirror, or semi-mirrored coating, offers a more subtle take on the technology. It provides the reflective benefits of a mirror but with a lighter coating that allows the eyes to be partially visible. This creates a stylish “fashion mirror” effect.

The Bottom Line: Flash mirrors bridge the gap between a standard tint and a bold solid mirror. They are perfect for customers who want the performance benefits of a mirror without the intense look, making them great for everyday wear.

Type 3: Gradient Mirror

Gradient mirrors are technically sophisticated coatings that are densest at the top and fade to clear at the bottom. This design is achieved through precise application techniques that vary the coating’s density across the lens surface.

For Example: Gradient mirrors are ideal for drivers and pilots. The darker top portion blocks bright overhead sun, while the lighter bottom section allows for a clear, unobstructed view of the instrument panel or dashboard.

The Core Benefits: Problem & Solution

Problem: Overwhelming Brightness & Glare

Solution: Superior Light Reflection

The main value of mirrored sunglasses is their ability to manage intense brightness that standard tints can’t handle. The metallic coating reflects harsh, direct sunlight away from the eye, acting as your first and most effective line of defense against brightness overload.

Pro Tip: Mirrored lenses are essential in high-glare environments. Snow reflects up to 80% of UV rays, and water creates intense horizontal glare. In these conditions, standard tints alone often do not provide enough protection.

The immediate result of this reflection is a noticeable reduction in the need to squint. When your eyes are not constantly fighting excessive brightness, you experience far less eye strain, fewer headaches, and greater visual comfort over long periods outdoors.

Problem: Harmful UV Radiation

Solution: An Added Barrier of UV Reflection

It’s important to understand how mirrored lenses protect you from UV rays. The primary defense comes from the lens material itself, but the mirror coating adds another layer of security.

Critical Warning: Your primary UV defense is the UV400 protection built into the lens material, not the mirror itself. Always confirm that any lens you source is certified as “UV400” or “100% UV Protection” at the material level.

The Bottom Line: A quality mirrored lens provides two forms of defense. The mirror coating first reflects a portion of UV rays away. Then, the UV-absorbing chemicals in the lens material itself block the remaining radiation from reaching your eye.

Problem: Poor Visual Clarity

Solution: Enhanced Contrast & Definition

Mirrored lenses can improve what you see by manipulating the light spectrum. The interplay between the base tint color and the mirror color can be engineered to enhance contrast and visual performance for specific activities.

For Example: A bronze mirror on a brown base tint will enhance contrast and depth perception. This combination is ideal for activities like inshore fishing or driving, where telling objects apart is key.

A blue mirror on a gray base tint is engineered to cut through haze on open water. The gray base provides true color perception, while the blue mirror reflects the scattered blue light that causes visual noise in marine environments.

Remember This: The color you see is determined by the base tint, not the mirror’s external color. A blue mirror does not make the world look blue; it simply changes how others see your glasses.

Mirrored vs. Polarized Lenses: A Comparison

The Fundamental Difference

Understanding the core distinction between these two technologies is essential for making smart product choices. They solve different problems and are not interchangeable.

- Mirrored Lenses: These lenses reduce overall brightness by reflecting light. Think of them like a volume knob for light, turning down everything equally, no matter the source.

- Polarized Lenses: These lenses work by filtering a specific type of light: horizontally-reflected glare. This is the blinding light that bounces off flat surfaces like water or a wet road.

Simple Analogy: A mirrored lens is like turning down the dimmer switch on a light in a room—it reduces all light. A polarized lens is like noise-canceling headphones that target and eliminate a specific, annoying sound frequency.

| Feature | Mirrored Lenses | Polarized Lenses |

| Primary Function | Reduces overall brightness | Filters horizontally reflected glare |

| Mechanism | Reflects light away from the lens | Absorbs specific light waves |

| Best For | Extreme sun, snow, high altitudes | Water sports, driving, fishing |

| Digital Screens | No issues | Can cause distortion or blackouts |

| Ice Visibility | Does not affect it | Can make icy patches harder to see |

The Bottom Line: For the ultimate performance, many premium brands now offer lenses that are both mirrored and polarized. This combination provides the brightness reduction of a mirror with the specialized glare-filtering of polarization, offering the best of both worlds.

Deciding Factors for Your Brand

When building your lens program, ask these key questions:

- What is my customer’s main activity? A deep-water angler has different needs than a mountain climber or an urban commuter. The primary use case should always guide your technology choice.

- What is the right balance of cost and value? Both technologies command a higher price. Mirrored lenses offer a visible, aesthetic upgrade, while polarization offers a performance benefit that is felt, not seen.

- How important is a visible technology statement? A mirror coating is an obvious and bold aesthetic choice. Polarization is an invisible feature. Decide if your brand story is about visible tech or unseen performance.

Behind the Reflection: The Science

What Are Mirror Coatings Made Of?

Modern mirror coatings are not just a single film of metal. They are a complex stack of microscopic layers of metals and dielectric materials, each calibrated to create a specific optical property.

- Metals Used: Common metals include titanium for durability, nickel for its reflective properties, and chromium for resistance to corrosion.

- Dielectrics Used: Materials like silicon dioxide and titanium dioxide are used to protect the metal layers and to fine-tune the color and reflectivity of the coating.

Key Metric: The color you see in a mirror coating is not from a pigment. It is the result of an optical interference effect created by the precise thickness of these layers, controlled down to the nanometer.

How It’s Made: Vacuum Deposition

The manufacturing process used to create these coatings is called vacuum deposition or PVD (Physical Vapor Deposition). It’s a high-tech process that ensures a perfectly uniform and durable coating.

- Preparation: The lenses are perfectly cleaned and mounted inside a sealed vacuum chamber.

- Vacuum: All air is pumped out of the chamber to create a near-perfect vacuum, removing any particles that could cause defects.

- Deposition: The coating materials (like titanium or silicon dioxide) are vaporized. This vapor then travels through the vacuum and condenses onto the lens surface, one atom at a time.

The Result: This process creates an optically pure, exceptionally durable coating that is permanently bonded to the lens.

A Guide to Durability & Care

Addressing Common Failure Points

The primary weakness of a mirrored lens is that the coating is on the exterior surface. This makes it more susceptible to scratches than a standard, uncoated lens.

Critical Warning: Scratches on a mirrored surface are highly visible and cannot be repaired. Even a tiny scratch breaks the reflective surface and creates a noticeable flaw. There is no way to polish it out.

Harsh chemicals and saltwater can also degrade the coating over time. The salt, moisture, and oxygen in a marine environment are particularly damaging to the metallic layers in the coating.

The Bottom Line: Proper care is not a suggestion; it is a strict requirement if you want mirrored lenses to last. They are less forgiving of casual handling than standard lenses.

The Professional’s Care Protocol

- Rinse First, Always. Before you wipe, rinse the lenses with lukewarm water. This flushes away any abrasive particles like dust or salt that would otherwise scratch the coating.

- Use a Gentle Soap. Apply one drop of a pH-neutral soap (like standard dish soap) or a dedicated lens cleaner. Avoid anything with harsh additives.

- Wipe Gently with Microfiber. Use only a clean, soft microfiber cloth to dry the lenses. A dirty cloth can trap particles and act like sandpaper.

Common Mistake: Never use paper towels, your t-shirt, or ammonia-based cleaners like Windex. Paper contains wood fibers that scratch, and ammonia will chemically damage the coating layers.

How to Spot a Premium Mirrored Lens

When sourcing products, look for these three markers of a high-quality, durable mirrored lens:

- Backside Anti-Reflective (AR) Coating: This coating on the inner surface of the lens prevents light from behind you from reflecting into your eye.

- Hydrophobic/Oleophobic Topcoat: This is a special treatment that repels water and oil, making the lenses easier to clean and preventing smudges.

- Integrated Hard Coat: The best mirror systems include a scratch-resistant hard coat as a protective outer layer to improve durability.

Conclusion

Mirrored sunglasses offer a powerful combination of performance and style. By understanding the science behind the mirror coating, the different types available, and how they solve specific visual problems, you can make smarter decisions for your brand. This knowledge empowers you to design better products, write more compelling marketing stories, and ultimately build a more credible and valuable eyewear collection.

Frequently Asked Questions

1. Does a blue mirror make me see the world in blue?

No. The external mirror color only affects what other people see. Your visual experience is determined by the color of the base tint underneath the coating.

2. Are mirrored sunglasses more expensive?

Yes, the complex vacuum deposition process required to apply the coating adds to the manufacturing cost, making them a premium feature compared to standard tints.

3. Can I get a mirror coating on my prescription glasses?

Yes. Mirror coatings can be applied to most prescription lens materials, including single vision and progressive lenses, to add style and performance.

4. Why can I see my own eye’s reflection in my lenses?

This is called “back-glare” and it happens when light from behind reflects off the inner lens surface. Premium mirrored lenses have a backside anti-reflective (AR) coating to stop this.

4. Are mirrored lenses the same as polarized lenses?

No, they are different technologies. Mirrored lenses reflect light to reduce overall brightness, while polarized lenses use a chemical filter to block specific, intense glare from flat surfaces.