The Recycled Acetate (r-Acetate) Production Process: A Step-by-Step Visual Guide

The r-Acetate production process uses chemical recycling to break down post-industrial acetate scrap to its basic molecular components. These components are then used to create new, virgin-quality material. The entire supply chain is audited via ISCC PLUS certification using a mass balance approach, which guarantees that for every kilogram of r-Acetate produced, an equivalent kilogram of waste was processed, ensuring traceable sustainability without sacrificing quality.

The Strategic Imperative: Mastering the r-Acetate Process

Your brand’s reputation depends on the authenticity of your sustainability claims. Without deep technical knowledge of the r-Acetate production process, you expose your company to significant reputational and financial risks that extend far beyond simple material selection. These risks include costly recalls, loss of consumer trust, and regulatory scrutiny.

The Business Risk of Unverified Sustainability Claims

Critical Warning: Major fashion and eyewear brands have faced public relations disasters when their “sustainable” claims were exposed as unsubstantiated marketing. Companies unable to demonstrate the technical validity of their r-Acetate sourcing risk losing consumer trust and experiencing significant stock devaluation.

The business impact of false claims is not just financial. Consumer trust, once damaged, requires years and substantial investment to rebuild. Your brand must provide detailed traceability from waste feedstock to finished frames to satisfy regulatory bodies and sophisticated consumers who demand proof of sustainability.

The B2B Strategic Value: De-risking Your Supply Chain

Research shows that 73% of global consumers will pay more for sustainable products, but 42% have lost trust in brands due to false environmental claims. Your ability to articulate the technical details of your r-Acetate sourcing is a technical fact. This means you can create marketing that is both compelling and defensible, which directly translates to market share protection and premium pricing opportunities.

Best Practice: Leading brands now demand that their suppliers provide detailed technical documentation. This includes feedstock certificates, processing technology verification, and third-party audit reports, which serve as both legal protection and powerful marketing ammunition.

Understanding the Modern Acetate Landscape

Your material selection strategy must account for the distinct performance and sustainability profiles of each acetate variant. Understanding these differences enables informed decision-making that balances environmental goals with your non-negotiable quality requirements and cost structure.

| Attribute | Virgin Acetate (Baseline) | Bio-Acetate (M49) | Recycled Acetate (r-Acetate) |

| Sustainability Profile | No recycled or enhanced bio-content. | Increased bio-based content (up to 68%). | Addresses waste via circularity. |

| Core Composition | ~42% bio-based cellulose, petroleum plasticizers. | ~68% bio-based content, plant-based plasticizers. | ~70% total sustainable content. |

| Recycled Content | 0% | 0% | ~28% certified recycled content. |

| Carbon Footprint | Highest (avg. 4.2 kg CO₂e/kg). | Lower than virgin. | Lowest (up to 56% reduction). |

| End-of-Life | Landfill or incineration. | Enhanced biodegradability. | Chemically recyclable (circular). |

| Cost Premium | Baseline cost. | 15-25% higher than virgin. | 15-30% higher than virgin. |

The Bottom Line: Recycled acetate represents the most comprehensive sustainability strategy. It combines waste stream utilization with chemical recycling technology to create virgin-equivalent materials, addressing both resource conservation and waste reduction while maintaining the performance required for premium eyewear.

The Core Technology Distinction: Chemical vs. Mechanical Recycling

Your supplier’s recycling technology directly determines the quality, consistency, and scalability of your r-Acetate supply. This technical distinction is essential for making informed sourcing decisions and avoiding quality failures that will damage your brand and your bottom line.

The Premium Standard: Chemical Recycling

Chemical recycling, like Eastman’s Carbon Renewal Technology (CRT), breaks down waste to the molecular level. This process uses temperatures over 1,000°C to completely depolymerize plastics into their constituent molecules. This means all contamination is eliminated, which directly translates to a final product that is chemically identical to virgin material.

Pro Tips: You must prioritize chemical recycling because it enables infinite recyclability without quality degradation. Unlike mechanical recycling, which shortens polymer chains and introduces impurities, this process resets the material to its original molecular state, guaranteeing virgin-equivalent performance.

The High-Risk Alternative: Mechanical Recycling

Mechanical recycling involves physically grinding, washing, and re-melting waste acetate. This is a technical fact. The functional implication is that this process introduces contamination risks and reduces polymer molecular weight. This directly translates to material degradation of 10-15% with each cycle, making it unsuitable for premium applications after only a few cycles.

Building the Business Case for r-Acetate

Adopting r-Acetate is a financial decision supported by quantifiable data and a powerful marketing narrative. You must leverage both to justify the investment and maximize your return through enhanced brand equity.

Data-Driven ROI: Carbon Footprint Reduction

Lifecycle assessments show r-Acetate frames achieve a 20-50% carbon footprint reduction compared to virgin acetate. When combined with bio-plasticizers, the total carbon savings can reach 56% for the material itself. This means you can report tangible progress toward corporate sustainability targets, which directly translates into data for mandatory ESG reporting and justifies a higher retail price.

Key Metric: Data from Ace & Tate’s 2022 Responsibility Report shows an 8% overall carbon footprint reduction for their Acetate Renew Bio frames, with the acetate material itself demonstrating a 56% reduction in carbon emissions. This is the level of specificity you must demand.

Marketing Advantage: The “Closed-Loop” Narrative

Your r-Acetate sourcing provides authentic content for marketing campaigns that resonate with consumers. The closed-loop story, where production waste becomes raw material for new frames, is a technical fact. This means you have concrete evidence of circularity, which directly translates into a brand story that is both compelling and legally defensible against greenwashing accusations.

For Example: Dick Moby’s frames made from 97% post-production waste demonstrate how production efficiency can create a powerful marketing narrative while delivering measurable environmental benefits.

The End-to-End Production Process Breakdown

Understanding the complete supply chain enables effective partner evaluation and quality assurance. The r-Acetate process involves specialized companies at each stage, creating multiple points where quality and sustainability claims must be verified.

Key Player Profile: The Chemical Recycler (e.g., Eastman)

Eastman’s Carbon Renewal Technology is the critical bridge between waste streams and new raw materials. The company’s commercial-scale gasification facilities provide the infrastructure necessary for large-scale r-Acetate production. Their ISCC PLUS certification enables mass balance tracking, which is the mechanism that validates recycled content claims.

Definition: Mass balance is a certified chain of custody model. It tracks the quantity of sustainable material through complex manufacturing processes where physical segregation is not practical, allowing recycled content to be attributed to specific outputs with auditable accuracy.

Key Player Profile: The Sheet Manufacturer (e.g., Mazzucchelli)

Mazzucchelli’s expertise is essential for converting recycled acetate flake into finished sheets suitable for eyewear. Their specialized processing knowledge ensures recycled content maintains the optical clarity and mechanical properties required for premium frames. Their own ISCC PLUS certification ensures the chain of custody is maintained from raw flake through to the finished sheets you purchase.

Stage 1: Feedstock Sourcing & Chain of Custody

Effective feedstock management is the foundation of credible r-Acetate production. Your ability to verify feedstock quality and traceability directly impacts the legitimacy of your sustainability claims and the consistency of your material supply.

Critical Warning: Many recycling claims rely on post-consumer content that cannot be effectively processed due to contamination. You must verify that your supplier’s feedstock consists primarily of post-industrial waste (clean production scraps) with a documented composition and processing history to avoid quality failures.

Stage 2: Advanced Chemical Recycling (Carbon Renewal Technology)

The gasification process is the technical core of r-Acetate. Acetate waste is shredded and fed into a high-temperature reactor, where it is converted into syngas (carbon monoxide and hydrogen). This syngas is then purified and serves as the fundamental building block for creating new, virgin-quality acetic anhydride.

Key Metric: The Carbon Renewal Technology process achieves greater than 95% conversion efficiency from waste feedstock to usable building blocks. This is a technical fact that means maximum material recovery and minimal waste, which directly translates to a more efficient and scalable circular economy.

Stage 3: Certified r-Acetate Sheet Creation

The final stage converts recycled building blocks into finished acetate sheets. Certified r-Acetate sheets combine approximately 43% bio-based cellulose and 27% recycled content, with the remainder being plasticizers and pigments. The recycled acetic anhydride ensures consistent color development and stability, allowing full access to your custom color palette without compromise.

Critical Warning: Acetate sheets must undergo a curing process lasting 6-12 months to achieve dimensional stability. Some manufacturers reduce this time to accelerate production. This creates materials that warp or crack later, which translates directly to higher production defect rates (25-40%) and erodes your profit margin. Always demand proof of adequate curing protocols.

The Supplier Vetting & Compliance Framework

You must implement a rigorous vetting process centered on verifiable certifications and technical audits. This is the only way to protect your investment and ensure the integrity of your supply chain.

The Non-Negotiable: Mandating ISCC PLUS Certification

ISCC PLUS is the only globally recognized standard for auditing recycled content through chemical manufacturing. Without this certification, any sustainability claim is unverifiable and legally indefensible. You must demand to see a supplier’s current certificate and ensure it covers the specific products you are buying.

The Bottom Line: The “mass balance” approach audited by ISCC PLUS does not guarantee specific recycled molecules are in your frame. It guarantees that an equivalent amount of recycled material entered the global supply chain to produce it. This provides a credible, auditable system that prevents greenwashing and underpins the entire circular economy for chemicals and plastics.

Actionable Checklist: Verifying ISCC PLUS Certification

- Verify Certificate: Use the official ISCC database to confirm the supplier’s certification is current and covers the correct materials.

- Demand CoC: Request a batch-specific Certificate of Conformity (CoC) with every delivery to verify recycled content claims.

- Conduct Audits: Periodically audit supplier facilities and documentation to verify ongoing compliance.

Building Your Technical Audit & Request for Quotation (RFQ)

Your RFQ must be a technical audit document. It must include specific questions and documentation requests that enable effective supplier evaluation and protect you from poor quality.

Critical Questions to Ask a Potential Partner:

- What are your specific feedstock sources, and can you provide composition data?

- What are your process’s yield rates from waste feedstock to finished product?

- Can you provide batch-specific testing data for mechanical stability, dimensional stability, and colorfastness as a condition of purchase?

Benchmarking Material Excellence: Quality Control

A head-to-head quality comparison proves that r-Acetate produced via chemical recycling is molecularly identical to virgin alternatives, providing equivalent performance across all critical quality metrics.

Technical Data Analysis: Proving Identical Performance

Laboratory testing confirms that r-Acetate materials exhibit identical mechanical properties to virgin acetate, including tensile strength and impact resistance. Chemical recycling is a technical process that resets polymer properties to virgin levels. This means there is no degradation, which directly translates to equivalent durability and stability in the final product.

Best Practice: You must demand performance validation against key eyewear standards. ISO 12870, for example, specifies tests for mechanical stability, bridge deformation, and lens retention. Your r-Acetate frames must demonstrate equivalent or superior performance to virgin acetate in all such standardized tests.

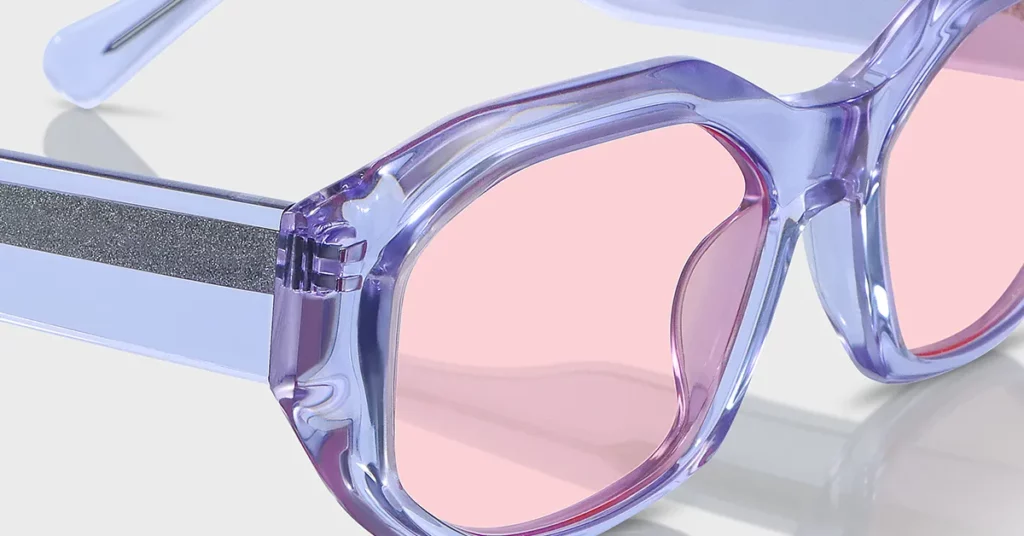

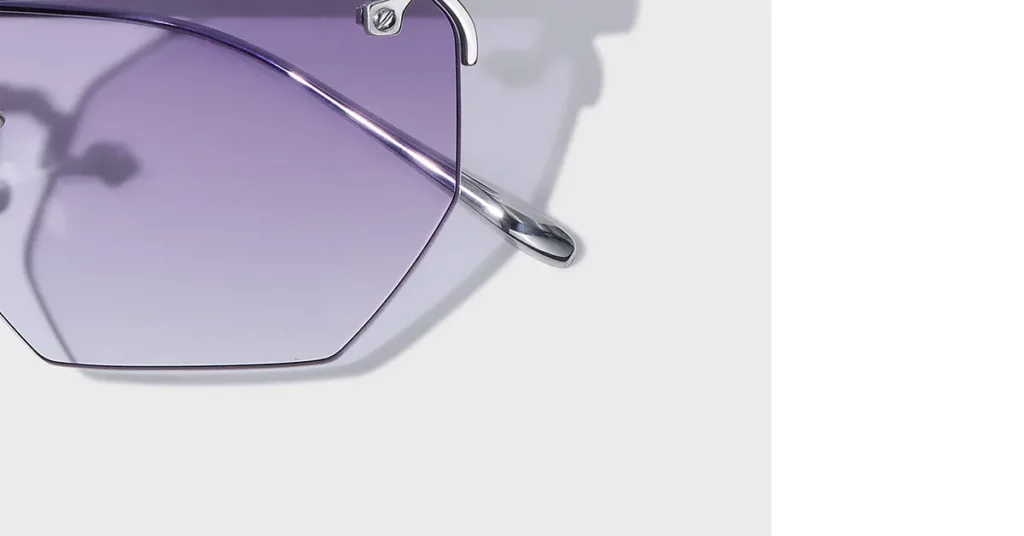

Quality Assurance: A Visual Library of Common Defects

Understanding potential defects enables effective quality control and supplier management. You must tie visual defects back to specific production failures to hold your partners accountable and protect your brand’s reputation for quality.

Root Cause Analysis:

- Brittleness: Typically caused by inadequate plasticizer, excessive heat, or contamination.

- Haze/Opacity: Often indicates moisture contamination or incorrect processing temperatures.

- Warping: Almost always results from inadequate curing time or improper storage.

Conclusion

A comprehensive understanding of the r-Acetate production process is your primary tool for de-risking sustainable material investments and selecting capable manufacturing partners. This technical knowledge allows you to differentiate authentic solutions from greenwashing, ensuring your products meet the quality standards that justify a premium price.

As a trusted handmade sunglasses eyewear manufacturer with transparent, ISCC PLUS-certified processes, Kssmi provides the expertise to integrate r-Acetate into your next collection seamlessly.

Frequently Asked Questions

1. Why should a brand mandate “chemically recycled acetate” in an RFQ?

Chemical recycling produces virgin-equivalent materials, while mechanical recycling degrades material properties. Accepting mechanically recycled acetate for premium eyewear introduces unacceptable risks of brittleness, poor finish, and color inconsistency.

2. Does “mass balance” mean my sheets may not contain recycled molecules?

Yes. Mass balance is an audited accounting method that ensures that for every kilogram of certified product sold, an equivalent kilogram of recycled feedstock entered the process. This maintains verifiable sustainability claims in a complex, efficient supply chain.

3. What is the lead time and cost for certified r-Acetate sheets?

Expect a lead time of 8-12 weeks, compared to 6-8 weeks for virgin acetate, due to feedstock and certification logistics. The cost premium typically ranges from 15-30% over virgin acetate, an investment often recovered through premium pricing.

4. How can a brand best leverage r-Acetate in marketing and ESG?

Focus on quantifiable data: specific carbon footprint reductions and waste diversion metrics. Use your ISCC PLUS certification number as proof. Highlight the technical sophistication of chemical recycling to differentiate your brand’s commitment.

5. If we provide our factory’s scrap, do we get a direct credit?

Under mass balance principles, your scrap contributes to the total certified recycled pool but does not create a direct one-to-one credit for your specific orders. However, it strengthens your brand’s circularity narrative and commitment.