What Is Acetate in Sunglasses: Composition, Benefits, Care

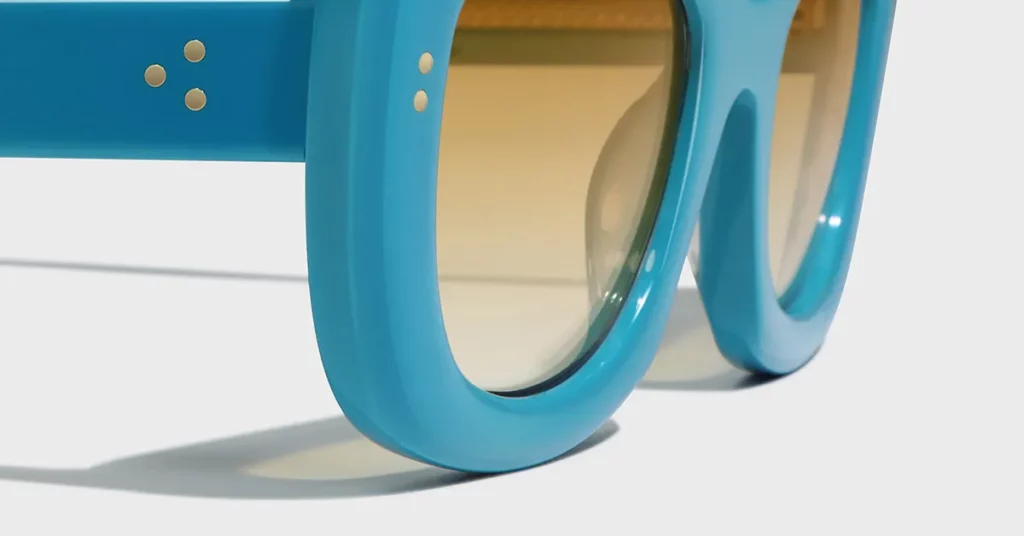

Acetate sunglasses are made from cellulose acetate, a plant-based bioplastic created from renewable wood pulp and cotton fibers. This premium material provides superior color depth, hypoallergenic qualities, and exceptional strength compared to standard injection-molded plastics. The process involves cutting frames from layered acetate blocks, resulting in embedded colors that will never fade.

What is Acetate? A Guide to the Premium Material

Understanding acetate starts with seeing it as a premium eyewear material. This sophisticated bioplastic is a major upgrade from typical plastic frames, offering special properties that have made it the top choice for luxury eyewear brands for over 70 years.

Understanding Cellulose Acetate

A Plant-Based, Semi-Synthetic Bioplastic

The core fact is that cellulose acetate is a plant-based plastic polymer derived from natural, renewable resources. This means it begins with cellulose, a natural fiber from cotton and wood pulp, which is then combined with acetic acid to create the acetate material. This bio-based origin makes acetate fundamentally different from petroleum-based plastics, building a more sustainable foundation.

Best Practice: When evaluating frame materials, always ask about the base polymer source. Acetate’s plant-based origin is a key quality differentiator from fully synthetic alternatives.

Not a Petroleum-Based Plastic

Unlike most plastics that are injected into a mold, acetate is built from a solid block of organic material. This distinction is important because it impacts both the environmental footprint and the manufacturing method. While standard plastic frames depend on fossil fuel derivatives, acetate frames hold onto their plant-based heritage through the entire production process.

Derived from Wood Pulp and Cotton

The journey from a plant to premium eyewear begins with wood pulp and cotton linters. Wood pulp gives the main cellulose structure, while cotton linters—the short fibers left on cotton seeds—add more cellulose content. These natural materials undergo a chemical process to become the acetate polymer, but their renewable source remains the core of the material’s sustainability credentials.

Also Known as Zyl or Zylonite

In the industry, you’ll often hear cellulose acetate called zyl or zylonite. These alternative names are common, with “zyl” being especially popular among frame designers and manufacturers. Knowing this terminology helps you understand technical sheets and professional conversations about eyewear materials.

First Used for Eyewear in the 1940s

Designers began using acetate in the late 1940s because it opened up new possibilities for style, color, and texture. This marked a major shift in eyewear design, moving past the limits of older plastics that were known for cracking and color fading. The material’s success in that era cemented acetate as the gold standard for premium frames.

The Anatomy of an Acetate Frame

Modern acetate frames are a product of sophisticated engineering. Each part is designed to maximize the material’s special properties. Understanding these elements helps you appreciate the craftsmanship behind quality acetate eyewear and spot superior construction.

The Frame Front (Cut from One Block)

The frame front is carved from a solid sheet of acetate by a CNC machine. This subtractive process is totally different from injection molding, where liquid plastic is poured into a mold. By cutting from a solid block, the frame’s layered color structure and consistent material density are perfectly preserved.

Simple Analogy: Think of it as the difference between carving a sculpture from a block of marble versus casting one from melted plastic. The carved approach maintains the material’s inherent integrity and artistic detail.

The Temples (Reinforced with a Metal Core)

“Temple shooting” is the process of inserting a metal wire core into the acetate temples by heating and forcing it in. This reinforcement is absolutely essential. This is because pure acetate temples would be too flexible. The metal core gives the necessary rigidity while letting opticians make precise adjustments for a custom fit.

Most Importantly: The metal wire core makes the temple strong and adjustable. This feature is what distinguishes premium acetate frames from mass-market alternatives and allows for a truly customized fit.

The Bridge and Nose Pads

The bridge is the part of the frame that rests on your nose, supported by the nose pads. In acetate frames, these parts can either be integrated directly into the frame front or added as separate components. The bridge often needs specialized bending to create the correct curvature for a comfortable, secure fit.

Hinges and Rivets

Hinges are attached to the frame front and temples using either heat insertion or rivets. Quality acetate frames use precision-engineered hinges that must be perfectly aligned and securely fastened. The process requires careful temperature control to avoid damaging the acetate while ensuring a durable connection.

Pro Tip: You can often see the metal wire core through a translucent acetate temple. This visibility is not a flaw; it is a sign of quality, showing that the manufacturer has invested in proper reinforcement for strength and adjustability.

The Designer’s Advantage: Why Choose Acetate

Acetate’s superiority over other plastics is clear when you look at its special properties. These traits give direct benefits to both the designers creating the eyewear and the people wearing the final product.

Benefit 1: Unmatched Color Richness

The most striking advantage of acetate is its approach to color and pattern. Instead of a surface coating, acetate’s coloration is part of the material itself, creating a depth and richness that is impossible to get with other methods.

- Embedded Color: The colors are built into the material in layers, giving it a three-dimensional quality. This layered structure creates what experts call “dimensional color,” where hues seem to have depth and movement as light passes through the material.

- No Fading or Peeling: Because the color is part of the material and not painted on, it will never chip, peel, or fade. This permanence is key to keeping the frame looking new over years of wear. Painted plastic frames show wear, but acetate holds its color integrity.

- The “Marble” Analogy: Think of it like the difference between a marble countertop and a laminate one. With acetate, the color and pattern run through the entire material. This is why acetate commands a premium—the color is authentic, not a thin surface decoration.

Benefit 2: Naturally Hypoallergenic

Acetate’s plant-based makeup makes it naturally compatible with skin. This addresses a common issue found in both metal frames and synthetic plastics, making it a safe choice for more customers.

- Plant-Based Origin: Because acetate is a plant-based material, it is hypoallergenic, which means it is very unlikely to cause an allergic reaction. The natural cellulose base is seen as non-threatening by the body.

- Ideal for Sensitive Skin: This makes acetate frames a great choice for people with sensitive skin or allergies to certain metals or plastics, like the nickel often found in metal frames.

- Health-Conscious Appeal: Its hypoallergenic nature makes it comfortable for long periods, which is perfect for everyday use. This benefit is very appealing to customers who prioritize health-conscious products.

Benefit 3: Strong, Durable, and Flexible

Acetate’s mechanical properties are a major step up from injection-molded plastics. The material’s mix of strength and flexibility creates frames that handle daily stress while keeping their shape and comfort.

- Stronger Than Plastic: Acetate is known for being stronger, more durable, and more flexible than regular plastic, which is often brittle and can break easily. This strength comes from its fibrous structure.

- Custom-Fit Adjustability: Acetate is a thermoplastic, which means it can be heated and molded to create a custom fit. An optician can easily adjust the temples and bridge for perfect comfort.

- A Long-Term Investment: The ability to adjust the fit over time means acetate frames have a much longer lifespan than non-adjustable ones. This longevity justifies the initial price, making it a smart investment.

Benefit 4: A Lightweight and Luxurious Feel

The tactile experience of wearing acetate frames adds to their premium feel. The material’s density and smooth surface create a distinctive feel that people connect with quality and craftsmanship.

- Comfortable for All-Day Wear: Despite its strength, acetate is a surprisingly lightweight material. This makes it comfortable to wear for long periods without creating pressure points.

- A Substantial, Warm Feel: High-quality acetate has a certain ‘heft’ and warmth to it. It feels more like a natural material (which it is) than a cold, sterile plastic.

- Luxury You Can Feel: The moment you pick up a pair of acetate frames, you can feel the difference. That substantial, smooth feel is a key indicator of a premium product and communicates quality instantly.

Acetate vs. The Alternatives

Understanding how acetate stacks up against other materials helps you make smart decisions. This comparison shows why acetate earns its premium price and customer loyalty.

Acetate vs. Injection-Molded Plastic

The core differences between acetate and standard plastic frames become obvious when you look at their key attributes.

| Feature | Acetate Frames | Injection-Molded Plastic |

| Material Origin | Plant-based (wood pulp & cotton) | Petroleum-based synthetic polymer |

| Manufacturing | Cut from layered blocks | Liquid injected into molds |

| Color Integration | Embedded within the material | Sprayed onto the surface |

| Durability | High strength & flexible | Brittle & prone to cracking |

| Feel & Finish | Premium luster & substantial weight | Hollow feel & dull surface |

| Adjustability | Heat-adjustable by an optician | Very limited adjustment |

| Cost | Higher production cost | Lower manufacturing cost |

The Bottom Line: You are choosing between craftsmanship and mass production. Acetate offers lasting color, custom-fit comfort, and a premium feel that injection-molded plastic cannot match. The higher cost reflects a genuine difference in quality and longevity.

Acetate vs. Other Popular Materials

Nylon/TR90: Craftsmanship vs. Sport Performance

Nylon frames are known for being tough, flexible, and resistant to heat and cold, making them perfect for sports. Acetate, on the other hand, is chosen for its rich colors and glossy finish. Choose acetate for fashion-focused designs where appearance matters most, and select nylon for activewear where impact resistance is the priority.

Metal Frames: Color Richness vs. Minimalist Style

While metal frames give a sleek, minimalist look, they cannot offer the endless color and pattern options of acetate. Metal excels in creating ultra-lightweight frames, but acetate provides superior design flexibility and a warmer appearance. The choice often comes down to personal aesthetic preference.

The Art of Creation: How Acetate Frames Are Made

Understanding how acetate frames are made reveals why they command a higher price. The process involves many specialized steps that separate handcrafted acetate from mass-produced plastic.

Stage 1: Creating the Raw Acetate Block

The journey begins by creating the foundational material. This first stage determines the frame’s color, stability, and performance.

- The Paste: It all starts with cellulose from cotton and wood pulp. Organic dyes are mixed with the raw material and acetone to create a paste-like substance. This is where unique color patterns are born.

- The Curing: The acetate blocks are then dried for several weeks to let solvents evaporate. This curing process is vital for the final quality, as it prevents the frame from shrinking or warping over time.

- The Result: This process creates the famous layered look of acetate. The final block contains rich, embedded color patterns that run through the entire material.

Critical Warning: Inadequate curing time is the main cause of frame deformation. Quality manufacturers allow several weeks for the acetate to fully stabilize before it is cut.

Stage 2: Cutting with CNC Machines

Modern acetate production uses computer-controlled machinery to achieve the precision needed for professional eyewear. This stage turns raw blocks into perfectly shaped frame components.

- The Slicing: Cured blocks are first sliced into sheets, called plates. The typical thickness is 6.0mm for frame fronts and 4.0mm for temples.

- The Carving: A CNC machine then carves the frame front, eye sockets, and other details from the acetate sheet. This ensures total consistency and allows for complex shapes.

Stage 3: Shaping and Reinforcing

After cutting, the flat components must be shaped into three-dimensional forms. This stage combines heat-forming with mechanical reinforcement.

- The Curve: The frame front is heated and pressed in a mold to create its facial curve. This curve is essential for proper lens mounting and a comfortable fit.

- The Reinforcement: A metal wire core is “shot” into the heated temples. This wire provides essential strength and allows an optician to make fine adjustments for a perfect fit behind the ear.

Stage 4: Tumbling and Polishing

Achieving acetate’s signature high-gloss finish requires a long polishing process. This stage is often cut short in lower-cost production, which results in a poor-quality surface.

- The Tumbling: The cut frame parts are placed in barrels filled with wood chips and polishing compounds. This tumbling action gradually smooths all surfaces.

- The Duration: This is a 48-72+ hour process. The frames are tumbled for days to smooth all rough edges and build a deep, lustrous shine.

Simple Analogy: This is similar to how river rocks are smoothed by water over many years. This patient process is what gives acetate frames their perfectly smooth, warm feel.

Stage 5: Final Assembly & Hand-Finishing

The last stage brings all the parts together and adds the final touches that define artisanal eyewear.

- The Hand-Polish: After tumbling, each frame is hand-polished by a skilled technician on a buffing wheel. This creates the final high-luster, glossy finish.

- The Assembly: Hinges are attached, temples are connected with tiny screws, and lenses are cut and mounted. This requires precise alignment to ensure the glasses function perfectly.

A Mark of Quality: How to Verify Acetate

Distinguishing high-quality acetate from lesser alternatives requires knowing what to look for. These tips will help you make informed decisions and avoid common quality issues.

The Visual & Tactile Test

You can quickly identify quality acetate with a few simple tests. These checks reveal the manufacturing quality and material characteristics that determine a frame’s performance.

- The Luster: High-quality acetate has a deep, liquid gloss. Low-quality acetate has a superficial shine that looks plasticky. The shine should appear to come from within the material itself.

- The Color: You should be able to see depth and layers in the color. In cheaper frames, the pattern will look flat or printed on. Look at the edge of the frame to see the pattern’s cross-section.

- The Feel: Good acetate has a certain density and smoothness. It feels solid and substantial. Cheap plastic feels light, hollow, and brittle in your hands.

- The Construction: There should be no seams or molding lines on an acetate frame because it’s cut from a solid block. All edges should be perfectly smooth and rounded.

Sourcing as a Quality Signal

Certain regions have earned reputations for producing high-quality acetate, reflecting their local expertise.

- Italian Acetate (e.g., Mazzucchelli): Known as the master of color blending. Italian producers excel at creating rich, complex color combinations and unique patterns.

- Japanese Acetate (e.g., Takiron): Known for being denser and harder. This high-density material holds its shape exceptionally well and can be milled thinner without losing strength.

- Chinese Acetate: Often associated with lower-cost production. While quality has improved, it can be less consistent. Remember This: Always judge a frame on its own merits, not just its country of origin.

Common Defects to Avoid

Understanding potential defects helps you spot problems and avoid frames that will fail. These issues often come from cutting corners in manufacturing.

- Frame Warping: If the acetate is not cured long enough, the frame may shrink or change shape over time. This is a serious defect that can cause lenses to pop out.

- A Dull Finish: A dull or uneven finish is a clear sign that the polishing process was rushed. A quality frame will have a consistent, deep gloss across all surfaces.

- Poorly Set Hinges: Hinges should be smoothly and securely embedded. If they look crooked or feel loose, it’s a sign of low-quality manufacturing.

A Guide to Acetate Frame Care

Proper maintenance will extend the life of your acetate frames and preserve their appearance. Following these simple rules helps avoid common causes of damage.

Best Practices for Cleaning

- Do: Clean with lukewarm water and mild soap. Use a pH-neutral soap to remove oils and dirt without harming the finish.

- Do: Dry with a soft microfiber cloth only. Other materials like paper towels or your shirt contain abrasive fibers that can cause tiny scratches.

- Do: Use two hands to take glasses on and off. This distributes stress evenly and prevents the hinges from misaligning over time.

- Do: Store in a protective hard case. This is the best way to protect your investment from impacts, scratches, and being crushed.

Critical Mistakes to Avoid

- Don’t: Leave frames in extreme heat. Never leave your acetate glasses on a car dashboard, as the high heat can cause the frame to lose its shape permanently.

- Don’t: Use harsh chemicals. Alcohol can damage the finish, and chemicals like acetone will literally dissolve the acetate material, destroying your frames.

- Don’t: Lay your glasses lens-down. Always place them with the lenses facing up to avoid scratching the lens surface and any special coatings.

Conclusion

Acetate stands as a top-tier eyewear material, blending plant-based origins with premium performance. Its value comes from a detailed manufacturing process that results in unmatched color depth, hypoallergenic comfort, and lasting durability. Choosing acetate is an investment in long-lasting style and quality, giving you a frame that is both beautiful and built to last. For your next project, use its story of craftsmanship to create a truly premium product.

Frequently Asked Questions

1. Is Acetate Better Than Plastic for Sunglasses?

Yes, acetate is considered superior to standard plastic. It is stronger, more flexible, and holds its rich, embedded color far better than surface-painted plastic frames.

2. Why Are Acetate Sunglasses More Expensive?

Acetate frames cost more because the production is complex and labor-intensive. The process involves carving from material blocks and extensive hand-polishing, unlike plastic frames which are quickly injected into a mold.

3. How Can I Tell if My Sunglasses Are Real Acetate?

Look for a deep, rich gloss and layered colors that appear to run through the material. Real acetate feels substantial and smooth and will have no molding lines or seams.

4. Can You Fix Warped or Bent Acetate Sunglasses?

Yes, an optician can gently heat an acetate frame to adjust its shape. This adjustability is a key benefit, allowing for a custom fit and restoration if the frame gets bent.

5. Is Acetate Environmentally Friendly?

Yes, acetate is a more sustainable choice than petroleum-based plastics. It is made from renewable, plant-based resources like wood pulp and cotton fibers.