Why Do Sustainable Materials Have Higher MOQs? A Manufacturer’s Explanation

Sustainable materials have higher MOQs due to specialized production economics. Limited raw material suppliers enforce large minimum purchases (300-500kg), while complex, certified processes require high-volume runs to amortize fixed setup and compliance costs. These factors create real cost pressures that manufacturers must pass on.

The Business Impact & Financial Risk of High MOQs

High minimum order quantities present significant operational challenges that extend far beyond a simple purchasing decision. You must view this as a core business variable where your sustainability goals collide with financial realities. This forces compromises that can directly slow your growth and limit your market responsiveness.

The Barrier to Entry and Innovation

Sustainable eyewear MOQs create an immediate financial hurdle. This differential is not arbitrary; it reflects the underlying economics of specialized production. You must analyze this difference as a primary input in your financial planning.

| Attribute | Standard Acetate | Sustainable Bio-Acetate | Strategic Implication for Your Brand |

| Typical MOQ | 100–200 units/style | 300–500 units/style | Higher upfront capital required, limiting collection breadth. |

| Replenishment Lead Time | 6–8 weeks | 12–16 weeks | Increased risk of stockouts and missed sales opportunities. |

The Bottom Line: A higher MOQ forces you to launch with fewer styles, limiting your ability to test the market and identify winning designs. Instead of an 8-10 piece collection, you might only afford 3-4, which directly reduces your brand’s initial market appeal and data-gathering capability.

The Strain on Cash Flow and Hidden Costs

High MOQs create immediate cash flow pressures that can cripple a growing brand. Committing to 4 sustainable styles at a 500-unit MOQ and a $15 manufacturing cost immediately ties up $30,000 in inventory. This is capital that cannot be deployed for marketing, technology, or market expansion.

Key Metric: For every $1 your brand ties up in excess inventory, you lose approximately $0.15-$0.25 annually in opportunity cost. This calculation must account for storage, insurance, and the returns you could have generated from investing that capital elsewhere.

Beyond the initial investment, high MOQs generate ongoing holding costs. Warehousing can run $0.50-$1.50 per frame per month, and administrative complexity multiplies. These hidden labor and system costs can consume an additional 5-8% of your inventory’s value annually.

The Amplified Risk of Obsolescence

Sustainable eyewear faces a unique obsolescence risk. Fashion cycles typically run 18-24 months, but the 12-16 week production lead times for sustainable materials significantly compress your selling window. This forces you into a “big bet” mentality where each product decision carries amplified financial risk.

Critical Warning: A 20% obsolescence rate on your sustainable inventory effectively increases your cost basis by 12-15%. This can completely erase the margin advantages you expected from your premium, eco-conscious positioning. Unsold sustainable stock often recovers only 20-40% of its original cost in liquidation channels.

A Manufacturer’s Cost Breakdown: The “Why” Behind the MOQ

Manufacturing MOQs exist because production economics demand sufficient volume to cover high fixed costs and achieve operational efficiency. You must understand these fundamentals to evaluate whether a manufacturer’s requirements are based on sound economics or are simply inflated.

The Core Calculation: The Production Break-Even Point

Every production run begins with fixed costs that are constant regardless of quantity. For acetate frames, this includes machine setup, tooling preparation, and quality system initialization, which collectively cost $800-$1,200 before the first frame is ever made. The break-even calculation divides these fixed costs by the contribution margin per unit.

Definition: Contribution margin is the revenue per unit minus the variable costs per unit. The aggregate contribution margin from all units in a run must cover the total fixed costs for that run to be profitable.

Fixed Cost Amortization and Labor Efficiency

The power of amortization explains why larger runs yield lower per-unit costs. A $1,200 setup cost amortizes to $4.00 per frame on a 300-unit run. That same cost amortizes to just $2.00 per frame on a 600-unit run. This is a direct, quantifiable efficiency gain that we can pass on to you.

This effect is magnified by labor dynamics. In my two decades on factory floors, I’ve consistently observed that a production line only hits peak efficiency on day 3 or 4. Key Metric: Labor efficiency improves 15-25% from day one to day four. Short runs prevent us from achieving this peak, forcing higher per-unit labor costs that must be offset by a higher MOQ.

The Sustainability Premium: Deconstructing Eco-Material Cost Drivers

Sustainable materials have higher MOQs because of specialized supply chains, complex production, and certification costs that do not exist for conventional materials. Understanding these drivers is the key to effective negotiation and strategic planning.

Sourcing Specialized Raw Materials

Conventional acetate is a commodity with dozens of global suppliers. Bio-acetate production, however, is concentrated among just 5-7 major suppliers worldwide. This lack of competition means suppliers can dictate terms, including higher MOQs. They require minimum orders of 300-500kg, enough for 800-1,200 frames, because their own equipment is specialized for niche production runs.

Critical Warning: A manufacturer claiming “flexible MOQs” on sustainable materials without a clear explanation of their supply chain strategy may be absorbing costs that will reappear later in the form of quality compromises or unexpected price increases. Demand transparency on their raw material sourcing.

Production Complexity and Certification Costs

Custom bio-acetate colors require complex chemical formulations that cannot be adjusted mid-production. The equipment requires 4-6 hours of cleaning between colors to prevent contamination, a process that generates 15-25kg of transition waste. These costs are only economically viable when amortized across a large batch.

Furthermore, proving sustainability is an auditable expense. ISCC PLUS and GRS certifications require chain-of-custody documentation and third-party verification, adding $200-$400 in direct administrative costs per batch. This is a fixed cost that must be spread across a sufficient number of units. Best Practice: Factor $0.20-$0.50 per frame into your planning for certification and traceability overhead.

A Strategic Framework for Managing High MOQs

Effective MOQ management requires financial modeling that goes beyond a simple per-unit price. Your approach must balance immediate cash flow impacts with the long-term strategic benefits of building a resilient, sustainable brand.

Calculate the Total Cost of Ownership (TCO)

Your TCO model must include the initial material cost, holding costs (at 15-25% of inventory value annually), obsolescence risk, and the opportunity cost of your capital. A comprehensive TCO analysis reveals the true financial impact of different MOQ levels and often shows that a higher per-unit price on a smaller run is superior to a lower price on a large one.

Consolidate SKUs to Share Components

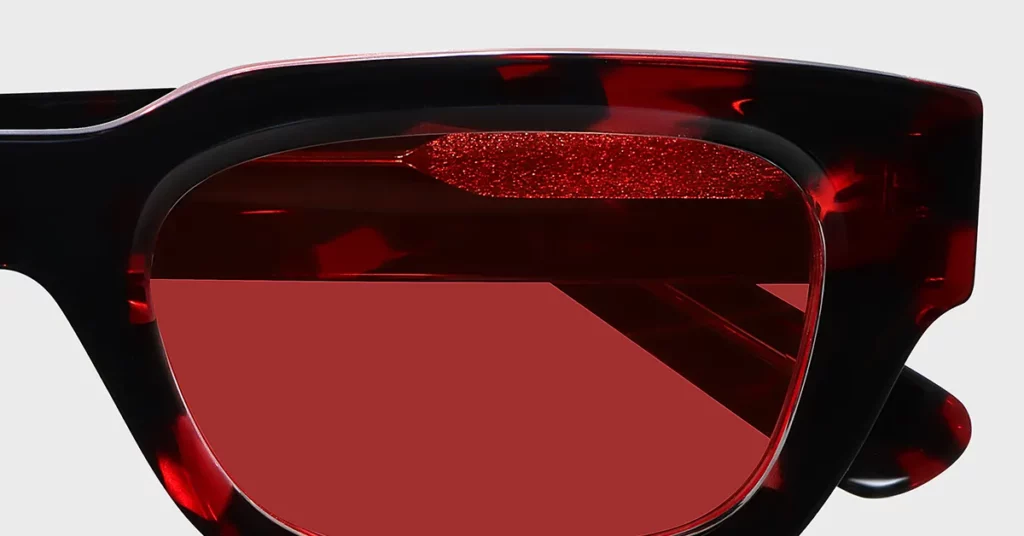

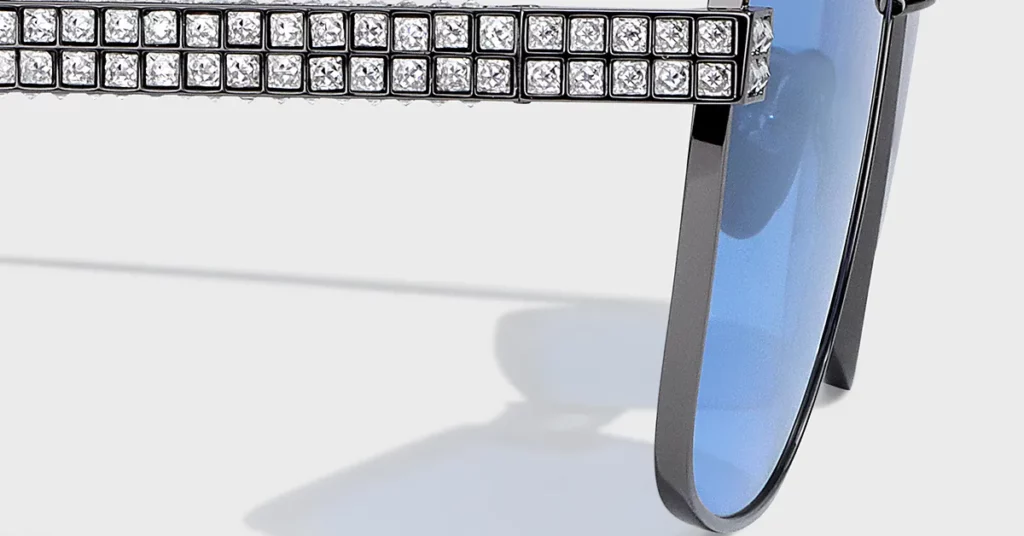

Strategic product design can dramatically reduce your effective MOQs. Prioritize creating design families that share common acetate colors, hardware, and lenses. This allows you to meet a supplier’s 500kg material MOQ while producing 4-5 different frame styles from that single batch, effectively reducing your per-style commitment.

Pro Tips: Design your collection around 3-4 core acetate colors that can support multiple frame styles. Then, introduce aesthetic variety through different shapes, finishes, and hardware combinations rather than relying on dozens of unique material colors.

Leverage Ready-Stock and Negotiate Smartly

Many manufacturers, including Kssmi, maintain ready-stock inventories of popular sustainable materials. This allows for lower MOQ runs, typically 100-200 units, perfect for market testing. You can validate a design with ready-stock material and then commit to a higher MOQ for a custom color once demand is proven.

Best Practice: When a standard MOQ is too high, propose a surcharge for a smaller run. A transparent manufacturer will be able to calculate the precise premium needed to cover the inefficiency of a below-MOQ run. This transforms the conversation from a “no” to a negotiation about price.

A Vetting Framework for a True Strategic Partner

Identifying a manufacturer who understands sustainable materials requires you to evaluate their policies, transparency, and flexibility. A true partner offers creative solutions, not just rigid requirements.

Demand a Line-Item Cost Breakdown

Always demand a detailed quotation that itemizes material costs, labor, setup fees, and overhead. A transparent manufacturer can show you exactly how fixed costs drive their MOQ. This separation of fixed and variable costs reveals where negotiation is possible. A partner unable to provide this lacks the sophisticated cost controls necessary for a long-term relationship.

Assess Their Willingness to Explain Their Rationale

A strategic partner will openly explain their MOQ rationale and even show you their own supplier’s requirements. They invest time in educating you because they view you as a partner in growth, not just a purchase order. Critical Warning: A manufacturer who is evasive about the “why” behind their MOQs is likely inflating them for their own convenience or profit.

Look for Flexibility and Pilot Programs

The best partners offer “low MOQ” pilot programs or test runs. These programs demonstrate a commitment to building a long-term relationship. A typical structure might offer a 150-unit run at a 15% price premium, with a commitment to standard pricing once your orders reach a sustainable volume. This is the hallmark of a partner invested in your success.

Conclusion

Understanding why sustainable materials require higher MOQs transforms this challenge from a barrier into a strategic planning opportunity. The premium reflects real production economics. By recognizing these fundamentals, you can build accurate financial models, negotiate intelligently, and select partners who offer transparency and flexibility.

The brands that win in sustainable eyewear will be those that develop sophisticated strategies to manage these realities, building competitive advantage through authentic, profitable sustainability. As a premier handmade eyewear manufacturer, Kssmi is structured to be that transparent, strategic partner for your brand’s growth.

Frequently Asked Questions

1. How does the MOQ for a custom-colored bio-acetate compare to a standard color?

Custom bio-acetate colors require 300-500kg MOQs (for 800-1,200 frames) due to setup costs and waste. Standard colors from ready-stock often have MOQs as low as 100-200kg because the material is already produced.

2. What production stage most impacts recycled acetate’s high MOQ?

The raw material extrusion stage has the highest MOQ impact. Recycled acetate requires specialized processing and batch consistency, demanding 300-500kg minimum production runs before any material can be converted into frame blanks.

3. What is the benchmark cost increase for sustainable acetate?

Certified sustainable acetate typically costs 15-35% more than standard acetate. Bio-acetate commands a 20-30% premium, while recycled acetate adds 15-25%, not including the additional per-unit costs for certification and traceability.

4. How do factory certifications influence MOQ policies?

Certifications like B Corp or SA8000 add fixed overhead costs for audits, documentation, and premium labor standards. These fixed costs must be amortized over larger production volumes, which indirectly supports higher MOQ policies to maintain profitability.

5. For a startup, what is more cost-effective: high MOQ on one SKU or low MOQ on multiple?

Launching multiple SKUs at a lower MOQ is almost always more cost-effective for a startup, even with higher per-unit costs. This strategy preserves cash flow, enables market testing, and reduces obsolescence risk, creating a total cost advantage of 10-20%.